Porcelain solar panel and manufacturing method thereof and puncher and positioning module applied in method

The technology of a ceramic solar panel and a positioning module, which is applied in the field of solar components, can solve the problems of high cost of the ceramic solar panel and difficult process of digging holes in the separator, and achieves the effects of avoiding deformation, being easy to observe, and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

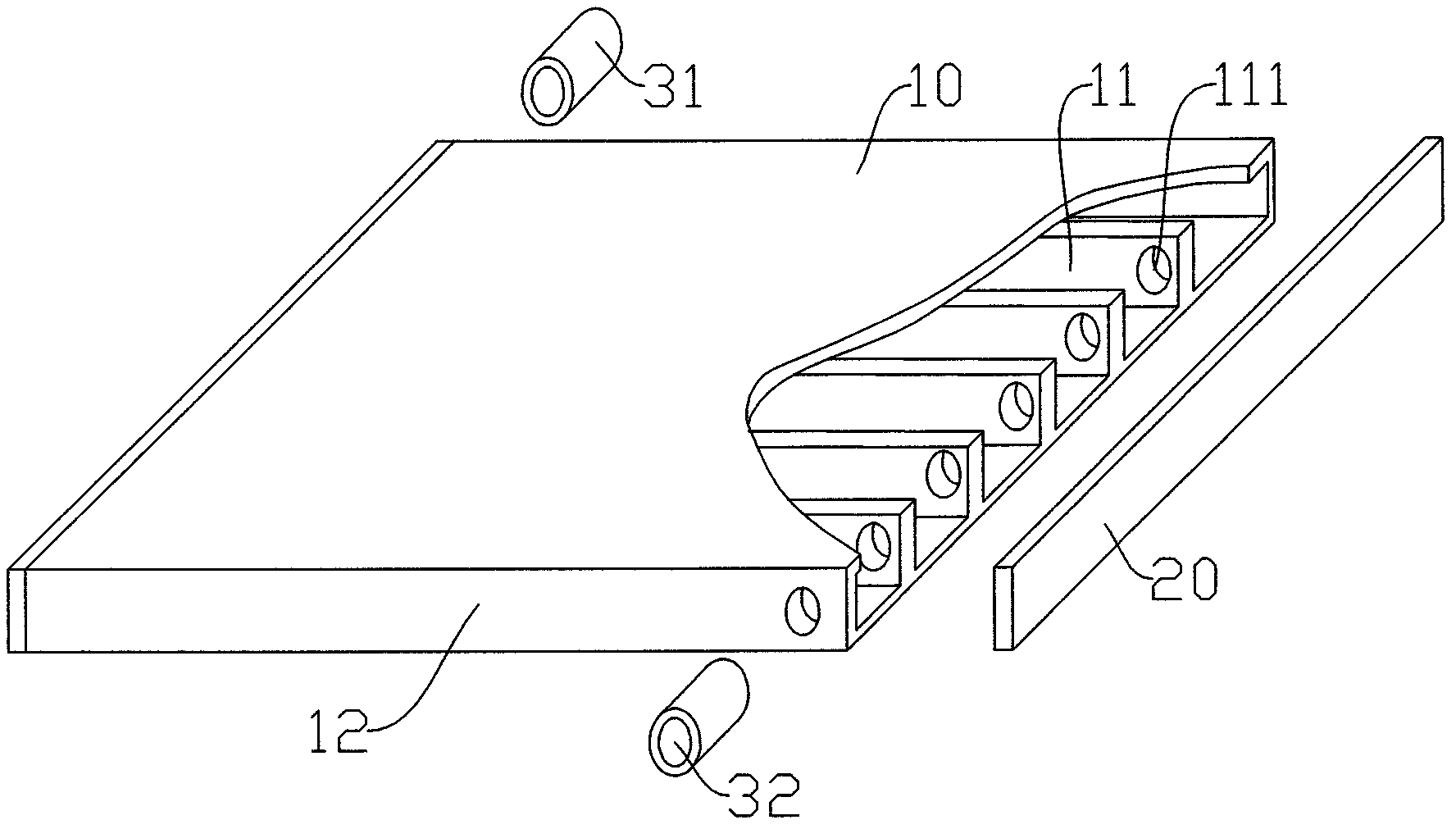

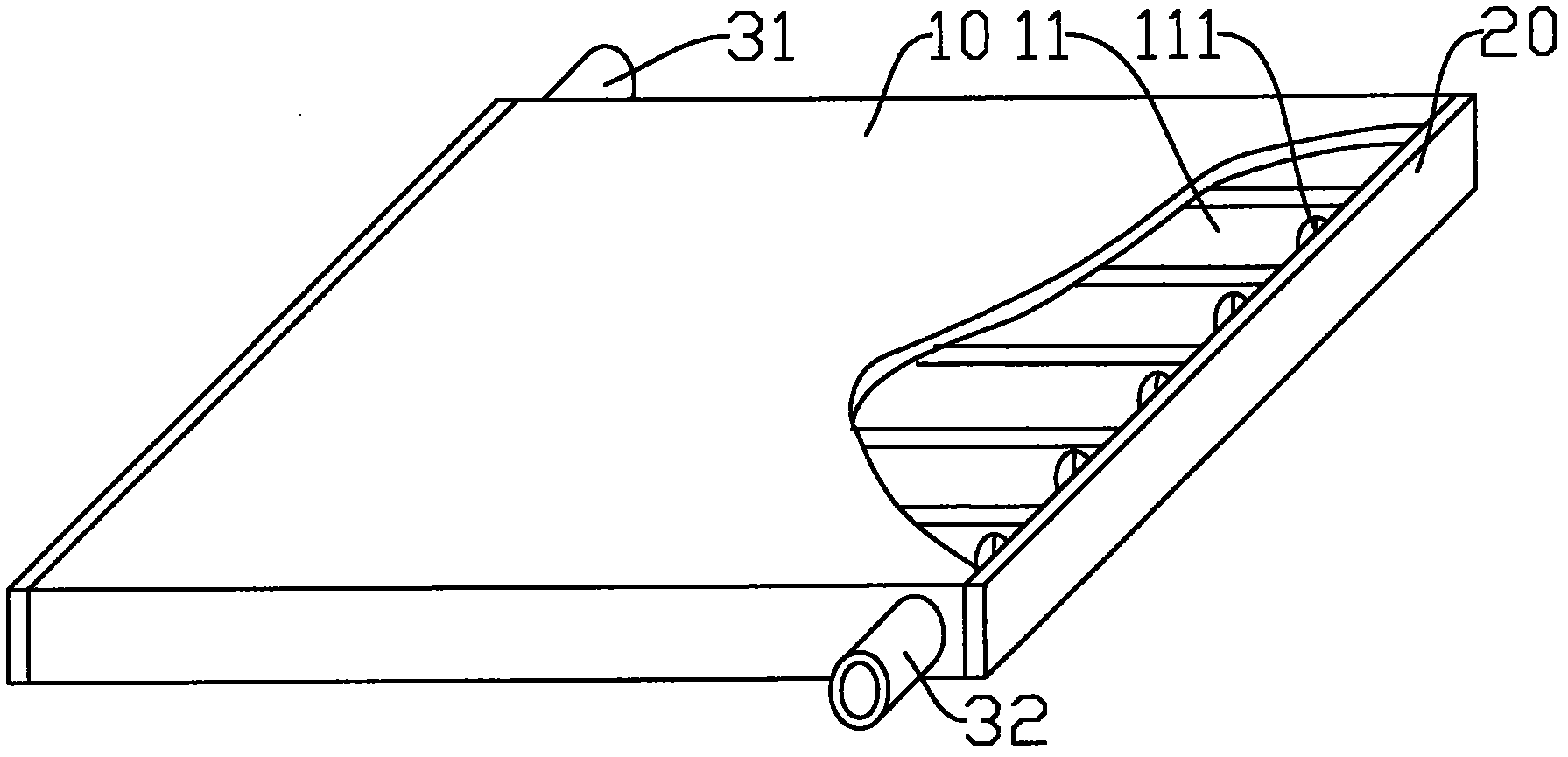

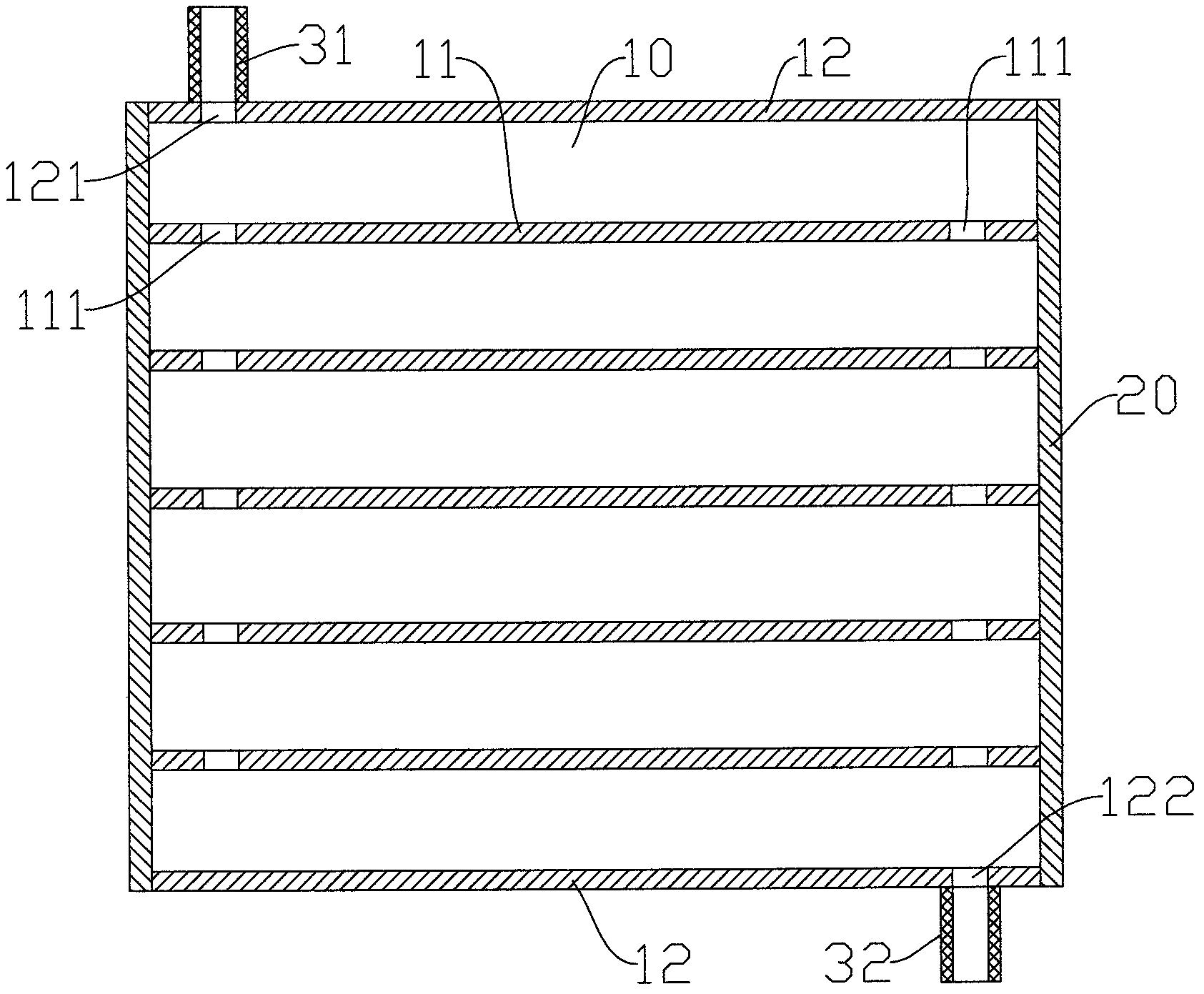

[0027] Examples, see Figure 1 to Figure 3 Shown: a ceramic solar panel, including a hollow body 10 . The hollow body 10 includes two side plates 12, and the two side plates 12 are respectively provided with a water inlet hole 121 and a water outlet hole 122. Apparently, the water inlet hole 121 and the water outlet hole 122 are respectively located on different sides in the longitudinal direction of the hollow body 10 . For example, the water inlet hole 121 is on the left side, and the water outlet hole 122 is on the right side, or vice versa. At the same time, at least one partition 11 is arranged longitudinally inside the hollow body 10 . That is, the partition plate 11 partitions the interior of the hollow body 10 into several closed cavities.

[0028] Both ends of the partition 11 are provided with throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com