a voltage transformer

A technology of voltage transformers and secondary windings, applied in the direction of inductors, transformers, transformer/inductor coils/windings/connections, etc., can solve the problems of different degrees of tightness, increase core loss, and affect product performance. Reach the effect of reducing turn length, saving silicon steel sheets, and reducing overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The content of the present invention will be further described in detail below.

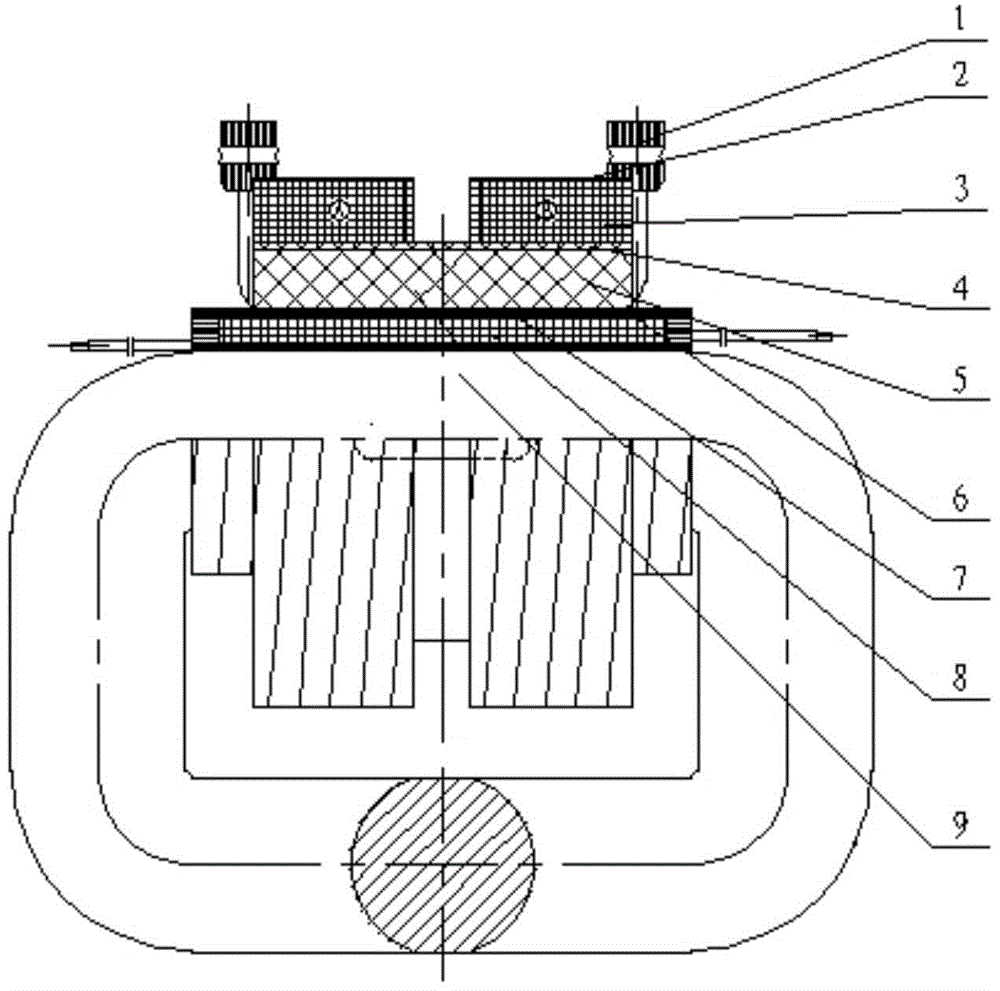

[0015] A voltage transformer, comprising a seamless annular iron core, a secondary winding, an insulating layer, a shielding layer, an epoxy resin mixed adhesive layer, a coil bobbin, and a primary winding are sequentially outsourced, and it is characterized in that the primary winding and the secondary The winding method of the winding is: on the seamless annular iron core, use the secondary numerical control winding machine to wind the secondary winding, and cover the secondary winding, insulating layer, shielding layer and epoxy resin mixed adhesive layer as a whole. A coil bobbin, on which a numerical control parallel winding machine is used to wind a primary winding, and the primary winding is rectangular or pagoda-shaped;

[0016] The seamless annular iron core is a hollow cylindrical iron core with an annular cross-section formed by coiling a cold-rolled grain-oriented silicon steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com