Connection method of high-temperature lanthanum chromite heating element

A technology of heating elements and wiring methods, which is applied in the direction of heating elements, ohmic resistance heating parts, etc., can solve the problems of screwing nuts and sliding teeth, easy damage of components, poor contact, etc. The effect of local heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

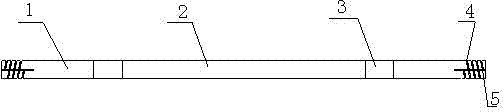

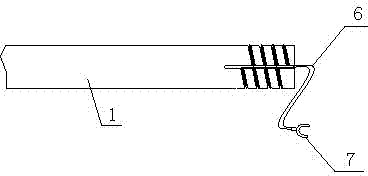

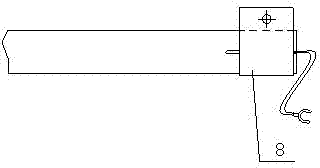

[0019] Embodiments, referring to the accompanying drawings, the blank of the lanthanum chromate high-temperature heating element is a cylindrical lanthanum chromate heating element blank of equal diameter. The heating element blank is composed of the cold end 1 of the heating element, the hot end 2 of the heating element, and the transition end 3 of the heating element. The overall length of the blank is 650 mm, the outer diameter is 18 mm, and the length of the cold end is 160 mm. The production process of the wiring method is as follows: the produced blank is dried and then processed. First draw the outline of the groove to be processed on the blank with a saw blade, and then soften the outline to be processed with a cotton rope dipped in deionized water. After the deionized water completely penetrates into the blank, use a steel wire Cut out a straight groove 5 longitudinally. The length of the straight groove is 25mm, the width is 1.5mm, and the depth is 0.5mm. shaped gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com