Lithium ion battery negative electrode material sintering and charging equipment

A technology for lithium ion batteries and negative electrode materials, applied in electrode manufacturing and other directions, can solve the problems of easy generation of dust, uneven pressing, slow speed, etc., to reduce adverse effects, ensure stability, and improve the effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

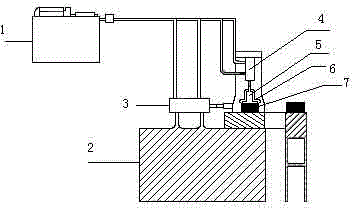

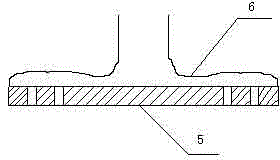

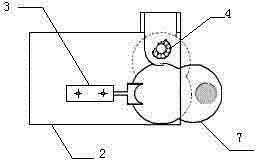

[0017] The following is based on figure 1 , figure 2 , image 3 The present invention is further analyzed, such as figure 1 , figure 2 , image 3 As shown, a lithium-ion battery anode material sintering and charging equipment is composed of a hydraulic station 1, a support bracket 2, a horizontal push cylinder 3, a lifting cylinder 4, a tablet press 5, and a crucible 7. The horizontal push cylinder 3 is arranged on the top of the support bracket 2; the crucible 7 is arranged on the other end of the top of the support bracket 2, and its geometric center is on the same horizontal line as the axis of the horizontal push cylinder 3; a lifting cylinder 4 is arranged directly above the crucible 7; The sheet 5 is connected to the shaft end of the lift cylinder 4; the sheet 5 is provided with a small hole; the sheet 5 material contacts the bread with a breathable cloth 6; the diameter of the sheet 5 is smaller than that of the crucible 7.

[0018] During work, the pressing shee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com