Strain gauge integrated three-dimensional turning force sensor

A sensor, turning force technology, applied in the direction of instruments, measuring force, measuring/indicating equipment, etc., can solve the problems of inability to test static force, charge leakage, high assembly accuracy, achieve simple and reliable assembly and maintenance, reduce mutual influence and Coupling, the effect of good temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

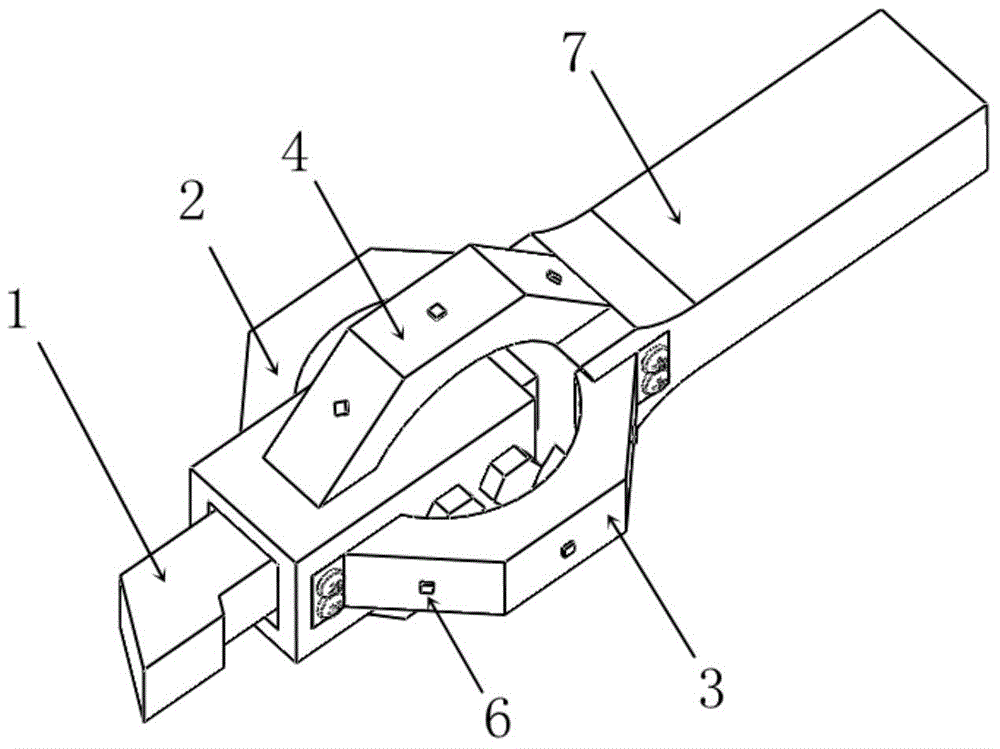

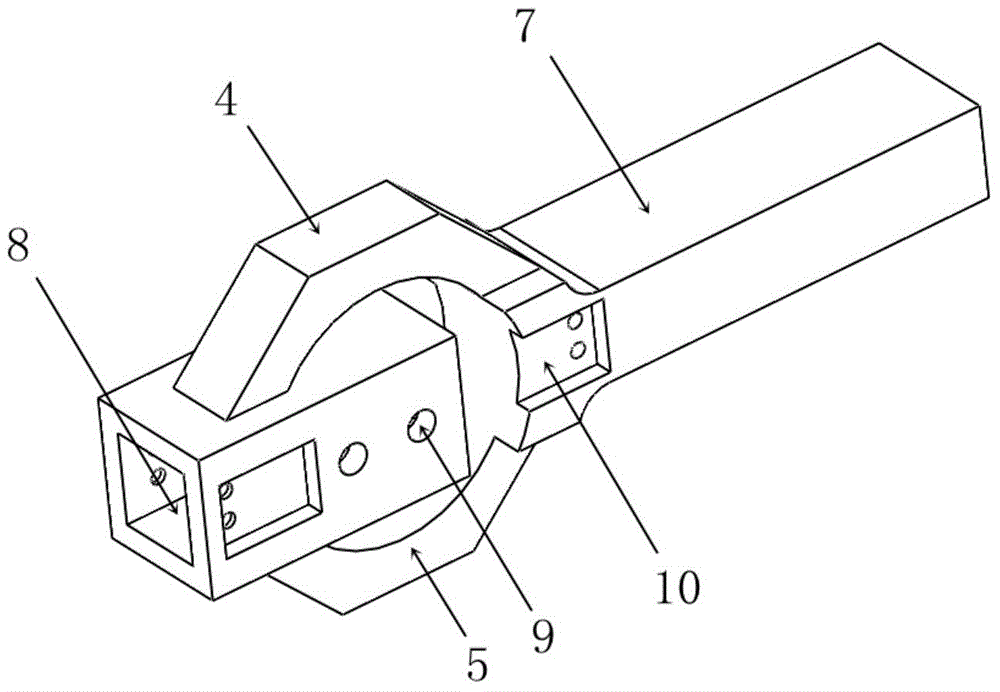

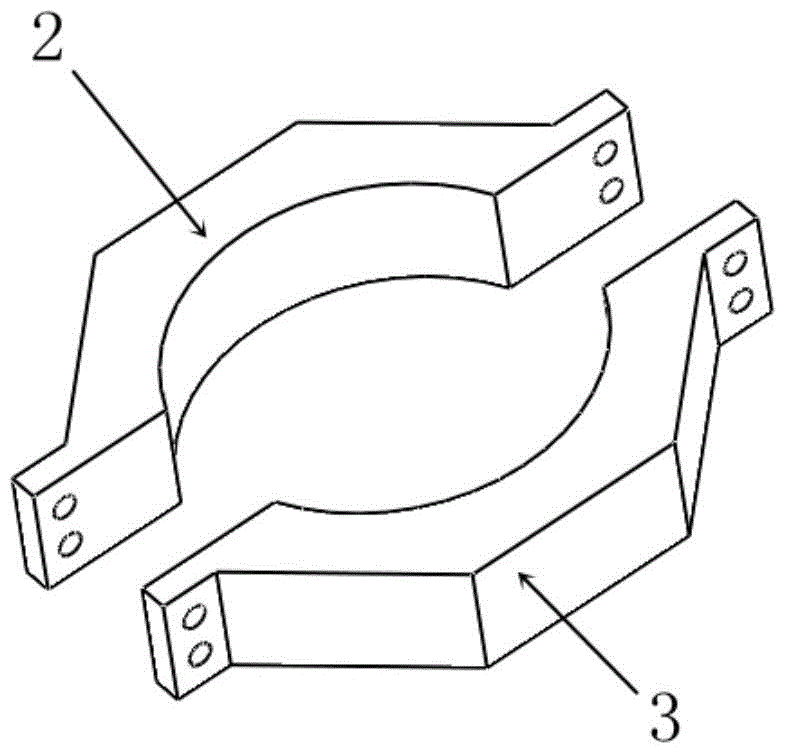

[0022] refer to figure 1 , figure 2 and image 3 , a strain gauge integrated three-dimensional turning force sensor, including a sensor main structure 7, a turning tool 1 is installed in the head turning tool slot 8 of the sensor main structure 7, and the turning tool 1 is fixed by bolts. The first vertical octagonal half-ring 4 and the second vertical octagonal half-ring 5 are respectively arranged on the upper and lower parts of the middle part of the sensor body structure 7, and the first vertical octagonal half-ring 4 and the second vertical octagonal half-ring 5 form a vertical octagonal ring , as an elastic body structure in the vertical direction; the front and rear sides of the middle part of the sensor main structure 7 are respectively provided with grooves 10 for connecting the first horizontal octagonal half-ring 2 and the second horizontal octa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com