Series-parallel hydraulic drive hybrid power vehicle power assembly system

A hybrid vehicle and powertrain technology, applied in hybrid vehicles, fluid hybrid vehicles, motor vehicles, etc., can solve the problems of high manufacturing cost, complex structure and shape, and difficult control, and achieve a reasonable matching effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

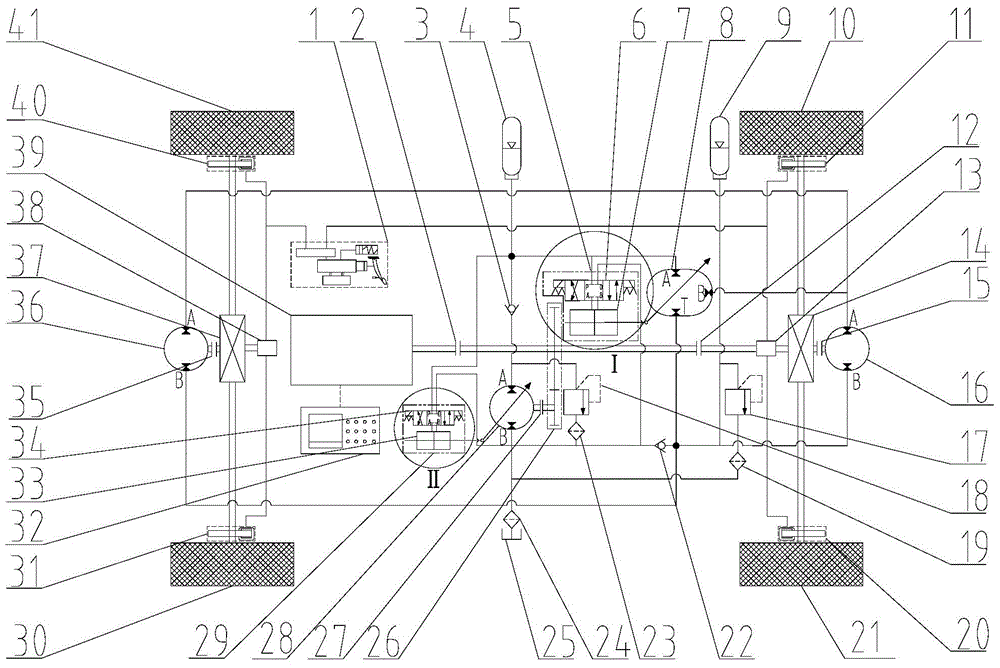

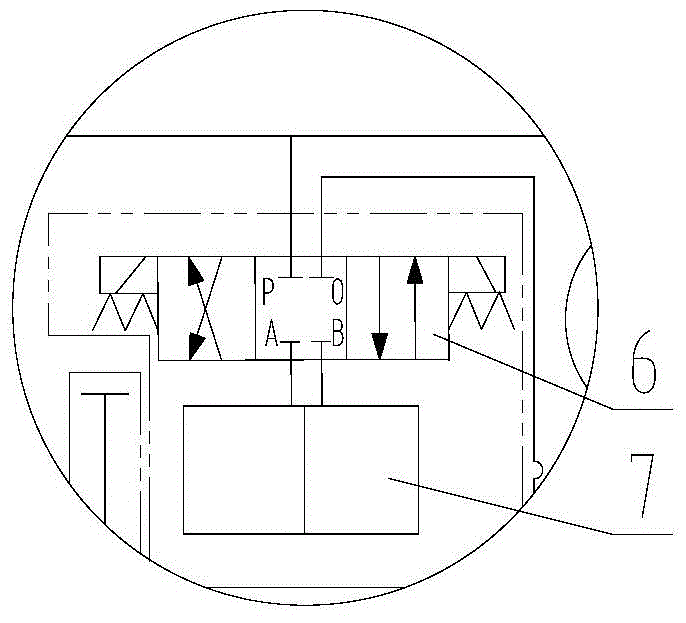

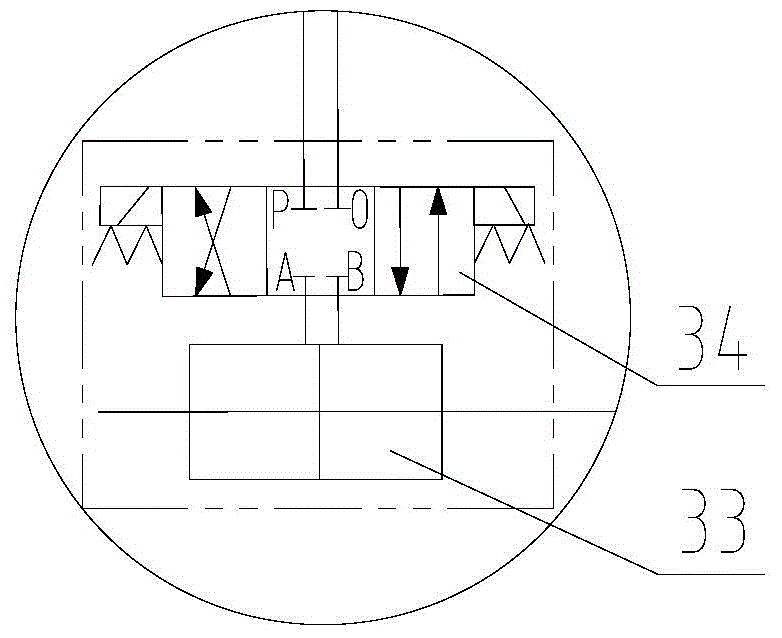

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] The powertrain system of the hybrid hydraulic drive hybrid vehicle of the present invention comprises a front axle load wheel transmission part, a rear axle load wheel transmission part, a vehicle general controller, an engine, a brake controller, a transmission shaft and a hydraulic transmission system; The output terminal of the dynamic controller 1 is respectively connected with the front axle friction brake I11 and the front axle friction brake II20 of the front axle load wheel transmission part, and the rear axle friction brake II31 and rear axle friction brake I40 of the rear axle load wheel transmission part. The output end is connected with the transmission shaft, and the vehicle master controller 32 is by receiving the torque value of the front axle torque sensor 13 of the front axle load wheel transmission part and the rear axle torque se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com