Method for extracting Mg, K, B and Li from mixed brine by utilizing natural energy

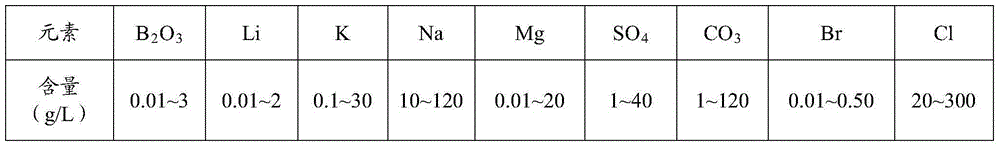

A technology of mixing brine and natural energy, applied in the direction of boron oxide, lithium carbonate;/acid carbonate, magnesium carbonate, etc., can solve the problem of low social and economic development level, difficult to determine the processing method, long distance transportation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0062] The composition of brine after secondary freezing and nitration (namely brine H) is Na + 3.94%, K + 4.89%, Mg 2+ 0.10%, Li + 0.42%, (CO 3 2- +HCO 3 - ) 0.13%, Cl - 12.27%, SO 4 2- 0.21%, B 2 o 30.81%, and the water alkali that is frozen and precipitated when preparing dew A in the first step is measured according to the ratio of the amount of Li in brine H to the amount of alkali in the mixed alkali as 1:0.5~1:3, and the solid-liquid separation is obtained after the temperature rise reaction. Crude lithium carbonate ore and brine I. The composition of brine I is Na + 6.92%, K + 4.06%, Mg 2+ 0.05%, Li + 0.10%, (CO 3 2- +HCO 3 - ) 0.68%, Cl-12.33%, SO 4 2- 2.19%, B 2 o 3 0.68%. The solid phase composition is Na + 8.56%, K + 1.90%, Mg 2+ 0.16%, Li + 10.24%, CO 3 - 44.60%, Cl-3.27%, SO 4 2- 10.60%, B 2 o 3 8.28%, and the lithium secondary yield was 60.91%.

[0063] In the tenth step, the brine I is introduced into the cooling pool, and bor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com