Stabilized soil applicable to intertidal zone sludge stable layer

A technology of solidifying soil and stabilizing layer, which is applied in the field of solidifying soil and can solve problems such as hindering the construction of infrastructure in coastal areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

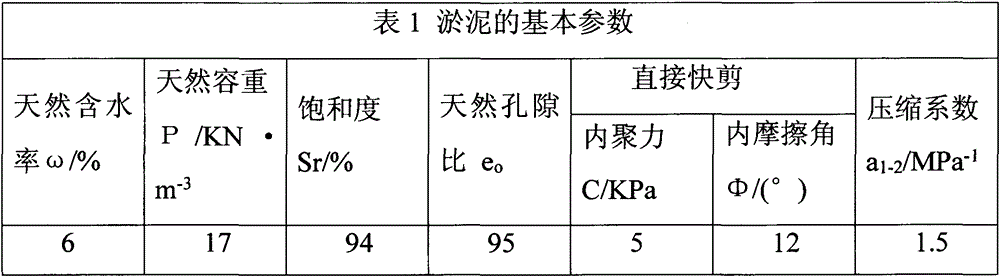

[0013] In the following examples, the tailings sand is phosphorus tailings sand, the fineness modulus is 2.8, and the composite zone II is graded; cement: Conch Group P·042.5 cement; mineral powder: S95 grade, fly ash is third-grade ash; gypsum is half water gypsum. The test silt was taken from the tidal flat silt at a depth of 1.5 meters underground in Xuwei New District, Lianyungang. The basic parameters of the silt are shown in Table 1.

[0014]

Embodiment 1

[0016] Dry the tailings sand first, so that the water content is controlled below 5%. The effective calcium oxide content of slaked lime in the curing agent should be between 60-80%. Component A is based on mineral powder: cement: fly ash: lime: Gypsum=50%: 25%: 12%: 10%: 3% by weight is accurately prepared.

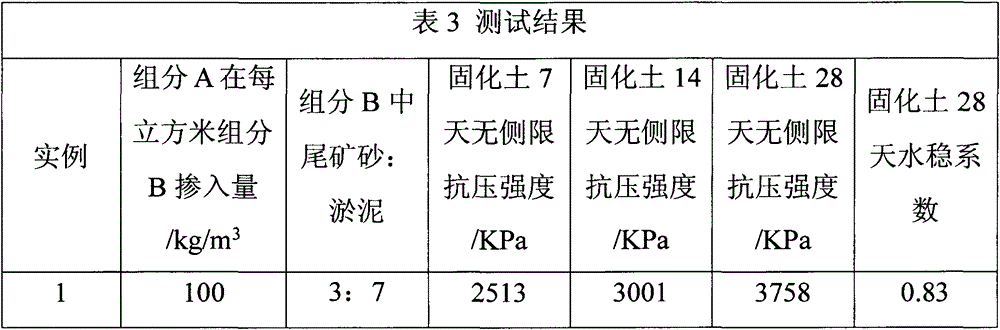

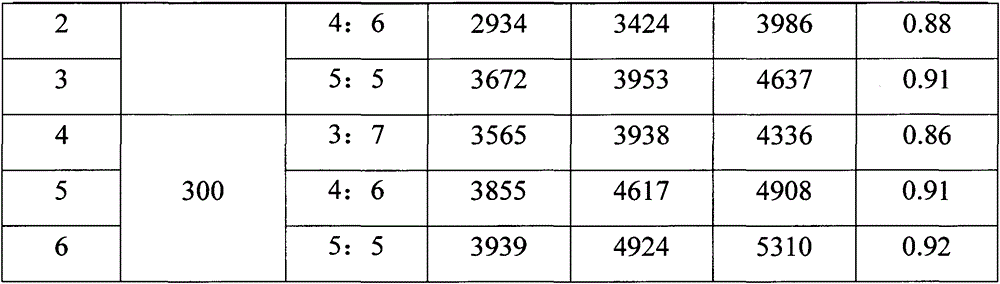

[0017] After mixing the components of curing agent A in the above proportions evenly, add 100kg and 300kg of component A to each cubic component of component B, and the mass ratios of tailings sand and silt of component B are 3:7 and 4 respectively. : 6, 5: 5, fully stirred evenly, according to the unconfined compressive strength test method (T0805-94) in the "Test Regulations for Highway Engineering Inorganic Binder Stable Materials" to prepare the solidified soil specimen and test the results. After static compaction molding, unloading, and demoulding to obtain the test piece, put it in a sealed humidity box and a constant temperature room for heat preservation, moistu...

Embodiment 2

[0021] Dry the tailings sand first, so that the water content is controlled below 5%. The effective calcium oxide content of slaked lime in the curing agent should be between 60-80%. Component A is based on mineral powder: cement: fly ash: lime: Gypsum = 30%: 40%: 10%: 15%: 5% by weight is accurately prepared.

[0022] After mixing the components of the curing agent A in the above ratio evenly, add 100kg and 300kg of component A to each cubic component of component B, and the mass ratios of tailings sand and silt of component B are 1:5 and 1 respectively. : 4, 1: 1, fully stirred evenly, according to the unconfined compressive strength test method (T0805-94) in the "Highway Engineering Inorganic Binder Stable Material Test Regulations" to prepare the solidified soil specimen and test the results. After static compaction molding, unloading, and demoulding to obtain the test piece, put it in a sealed humidity box and a constant temperature room for heat preservation, moisturizin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com