Soil solidifying agent with high water-resistance and application thereof

A soil curing agent and water-based technology, applied in the field of construction chemistry, can solve the problems of poor soil adaptability, insufficient water resistance, and high cost, and achieve the effects of improving saturation/compactness, facilitating popularization and use, and improving social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

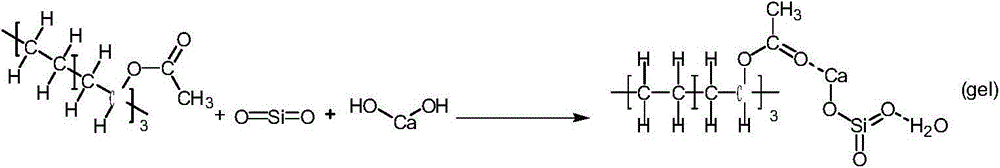

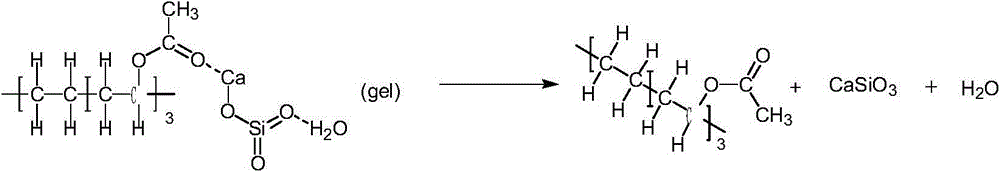

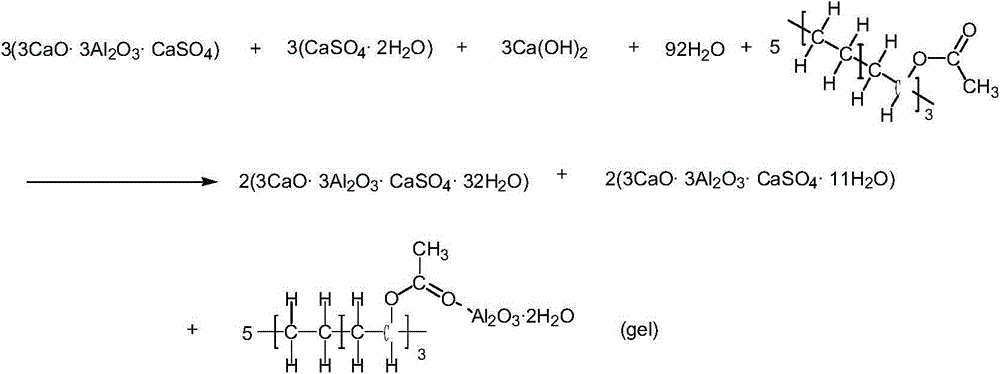

Method used

Image

Examples

Embodiment 1

[0031] VAE (vinyl acetate content 75%) 50%, aluminum dihydrogen phosphate 5%, 1% vinyl acetate solution 42%, aluminum oxide 3% with an average particle size of 60nm.

Embodiment 2

[0033] VAE (vinyl acetate content 70%) 53%, aluminum dihydrogen phosphate 3%, 1% vinyl acetate solution 42%, aluminum oxide 2% with an average particle size of 80nm.

Embodiment 3

[0035] VAE (vinyl acetate content 75%) 55%, sodium aluminate 2%, 1% vinyl acetate solution 41%, aluminum oxide 2% with an average particle size of 100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

| Splitting tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com