Novel heating mantle

A heating cover, a new type of technology, applied in textiles and papermaking, lamination devices, lamination, etc., can solve the problems of unevenness, slow heating of the heating cover, etc., achieve the effect of fast temperature rise and drop, increase vehicle speed, and realize temperature edge compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

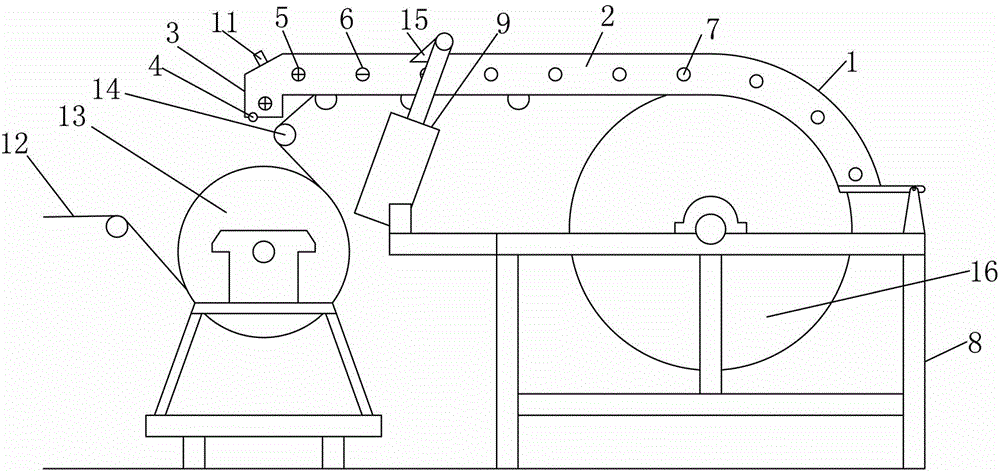

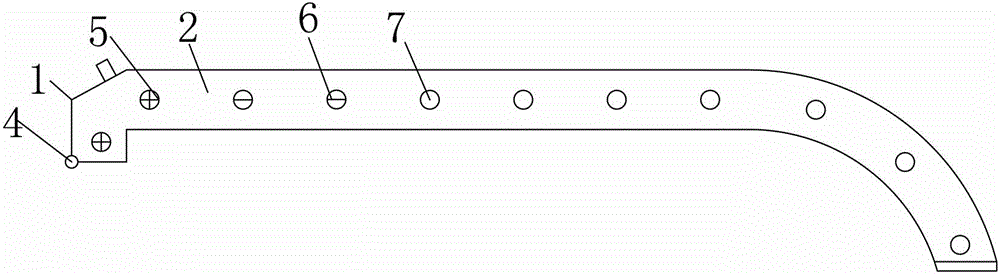

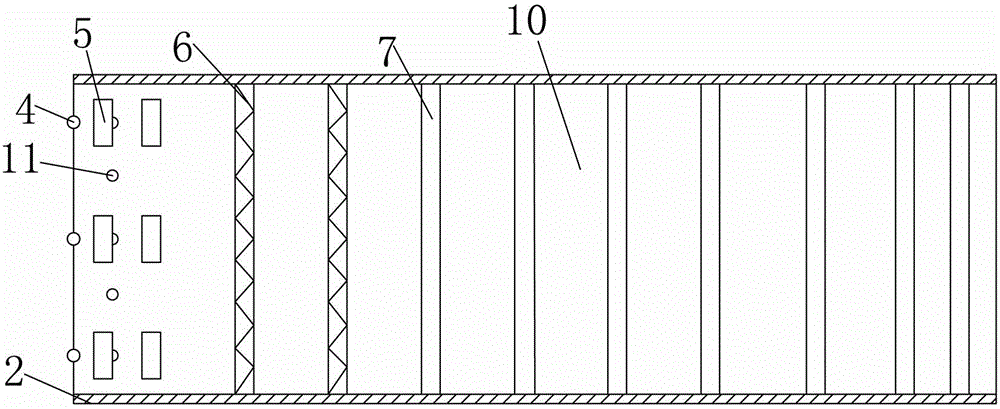

[0010] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0011] Depend on Figure 1 to Figure 3 Given, the present invention includes a frame and a heating cover body whose right end is rotatably fixed on the frame. The front and rear sides of the heating cover body 1 are provided with heat preservation side plates 2, and the left part of the side section of the heating cover body 1 is linear, and the right part is linear. Semi-circular, the left end of the heating cover body 1 has a "7"-shaped bend 3 downward, and a plurality of thermocouples 4 are arranged longitudinally at the port of the bend 3, and the heating cover body 1 on the right side of the thermocouple 4 is horizontally spaced There are multiple groups of gold heating short tubes 5 arranged at vertical intervals and corresponding to the thermocouples 4. The heating cover body 1 on the right side of the gold heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com