Suspended-cable steel-concrete composite-structured submerged floating tunnel and construction method therefore

A combined structure and suspended in water technology, which is applied in basic structure engineering, water conservancy engineering, underwater structures, etc., can solve the problems of cumbersome construction methods and large amount of steel materials, and achieve simple construction methods, reduced usage, and stable driving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

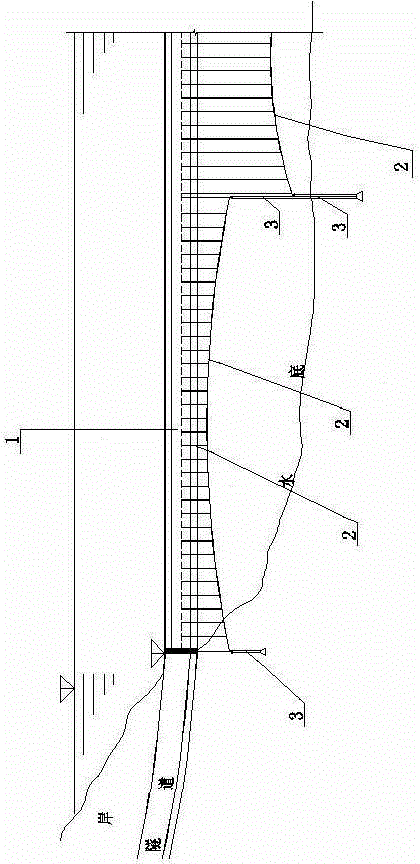

[0024] Such as figure 2 As shown, the tunnel body of this suspension steel-concrete composite structure suspended tunnel in water is a steel-concrete composite shell with an outer contour diameter of 10 to 15 meters. 3 are connected, relying on the tension of the suspension cable and the buoyancy of the structure to stabilize the floating tunnel 1 in the water, control the displacement and deformation of the tunnel within the allowable range, and ensure the structural safety of the tunnel and smooth driving. The steel-concrete composite shell is formed by sprinkling fine stone concrete 6 between the inner steel plate 5 and the outer steel plate 4. The two steel plate layers are used as the outermost layer and the inner shell of the floating tunnel body, and the pressure between the two steel plate layers is The fine stone concrete 6 is sprayed with a spray gun as the inner lining to form a steel concrete composite shell; in this embodiment, the tunnel cylinder is a single cyl...

Embodiment 2

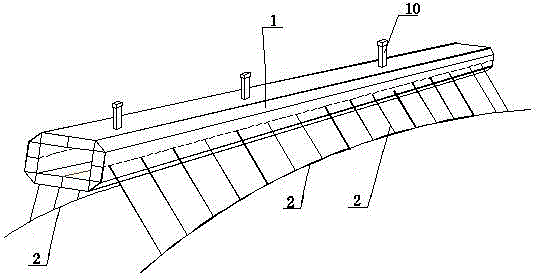

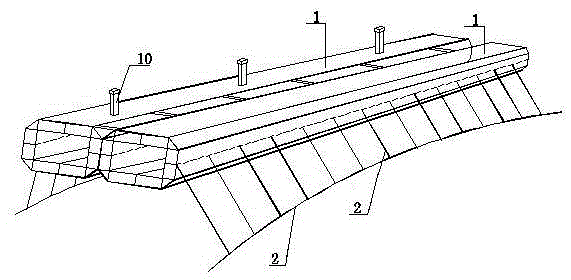

[0033] combine image 3 , Figure 4 As shown, the tunnel body of this suspension steel-concrete combined structure floating tunnel in water is composed of two barrels arranged side by side, and the two barrels are connected to each other by high-strength bolts 8 at the side walls. A supporting frame 7 is provided in the tunnel body, and the supporting frame 7 is formed by connecting a longitudinal diaphragm and a transverse diaphragm. A secondary channel 14 and a gap are formed between the support frame 7 and the housing, and the support frame constitutes a driving lane 13, which is two lanes. The conveying pipeline is laid in the secondary passage 14, and a partition is laid on the conveying pipeline to form a passage. A secondary channel at the side wall of the tunnel body is an emergency evacuation channel, and the secondary channel is provided with an evacuation port 11; the upper part of the tunnel body is provided with an automatic drainage device 9 and a vent 10, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com