Bauxite environmental protection sound-absorbing board

A technology of bauxite and sound-absorbing panels, which is applied in the direction of sound insulation, noise-absorbing devices, building components, etc. It can solve the problem of unsatisfactory use of the overall strength and bending resistance of the sound-absorbing panels, broken or shattered sound-absorbing panels, and sound-absorbing panels. Breaking and falling off, etc., to achieve good adhesion, fast demoulding speed, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with embodiment the present invention will be further described:

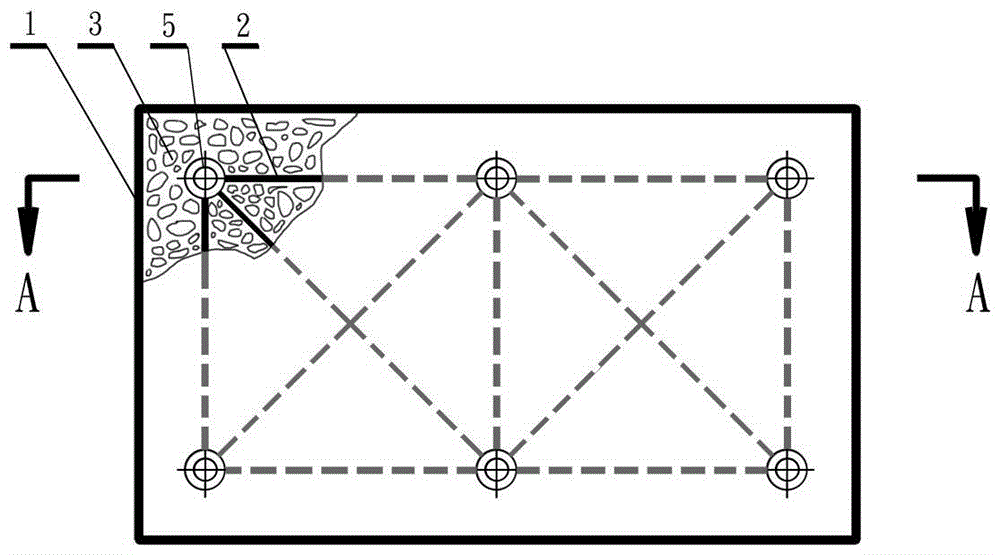

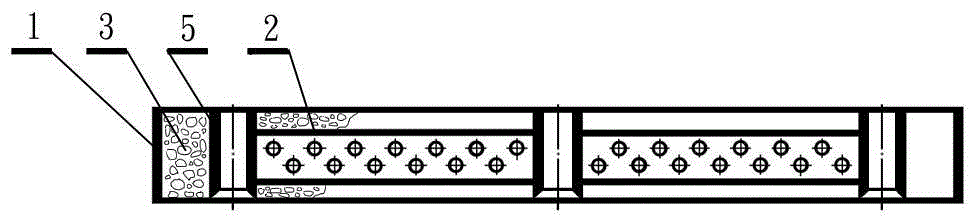

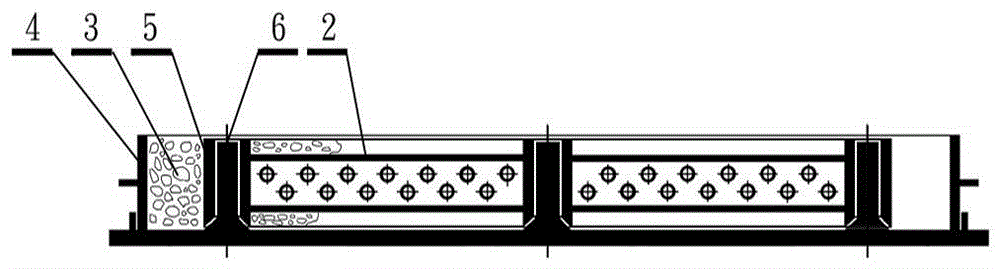

[0035]The bauxite environmental protection sound-absorbing board is a rectangular plate-shaped object 1, which is composed of a built-in frame 2 and a bauxite composite foaming agent 3. The built-in frame 2 is designed with 6 short steel pipes 5; the built-in frame 2 is laid flat On the mold 4, after the short steel pipe 5 in the built-in frame 2 is inserted into the column 6, the bauxite composite foaming agent 3 is used to cast it on the periphery of the built-in frame 2, and the built-in frame 2 is completely embedded in the bauxite composite foaming agent 3 After 6 days of standing and curing, the semi-finished bauxite environmental sound-absorbing panel is taken out of the mold and transported to the tunnel kiln for roasting. The roasting temperature is controlled at 600-700°C , the roasting time is controlled at 6 hours, and after cooling, it is packaged as a finished product o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com