A 10kw wind turbine blade

A technology of wind turbines and blades, which is applied to wind turbine components, wind turbines, engines, etc. It can solve the problems of low utilization rate of wind energy and high cost per kilowatt-hour of electricity, and achieve slow stall characteristics, reduce wind resistance, and enhance cohesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

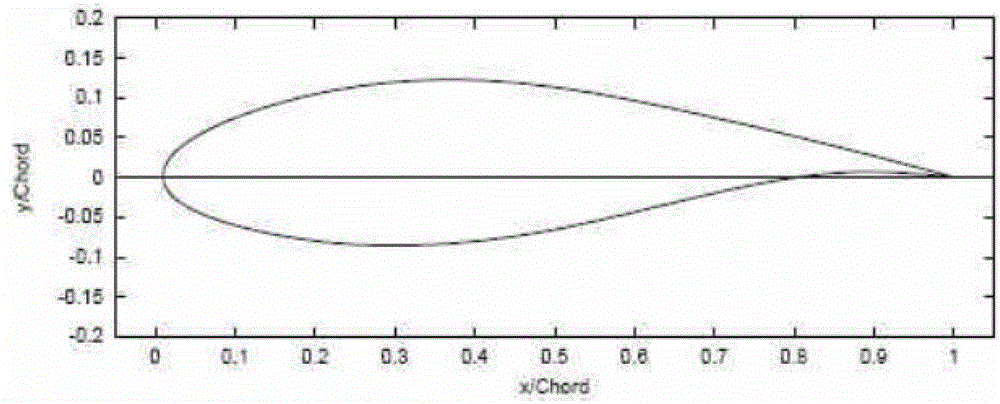

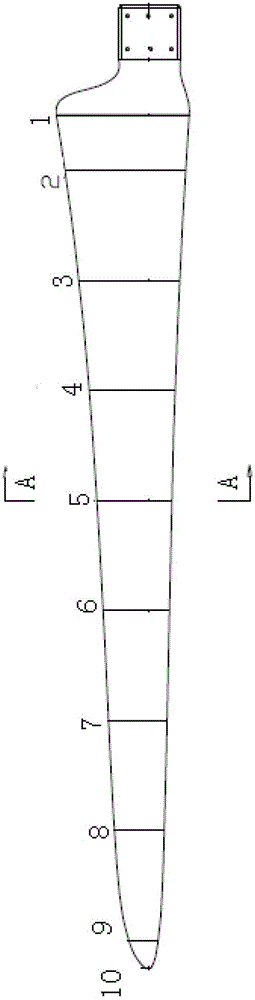

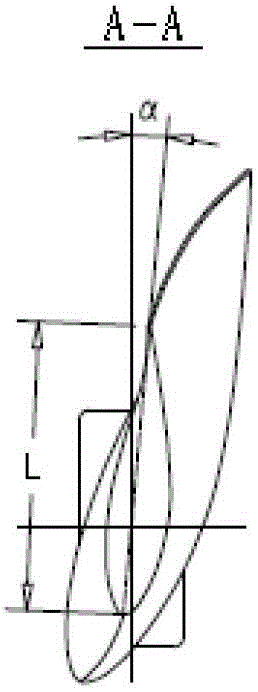

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings. The blade that the present invention selects and is used for optimizing is Dutch DU93-W-210 airfoil, and its cross-sectional shape is as follows figure 1 Its aerodynamic coefficients are shown in Table 1. Among them, the design principle of DU93-W-210 airfoil is: the outer airfoil has high lift-to-drag ratio, high maximum lift, gentle stall characteristics, insensitivity to roughness and low noise.

[0034] Table 1 DU93-W-210 airfoil aerodynamic coefficient

[0035] α

Cl

CD

-180.0

0.0000

0.0101

-170.0

0.4397

0.0510

-160.0

0.8794

0.1688

-150.0

0.7457

0.3492

-140.0

0.6721

0.5705

-130.0

0.5892

0.8057

-120.0

0.4769

1.026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com