Light bolt fastening piece as well as manufacturing method and mold thereof

A bolt fastener, lightweight technology, applied in the direction of threaded fasteners, bolts, manufacturing tools, etc., can solve the problems of unguaranteed delivery cycle, high price, huge demand for light bolt fasteners, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

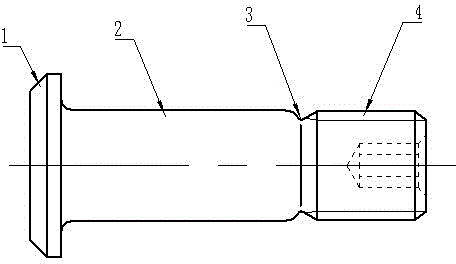

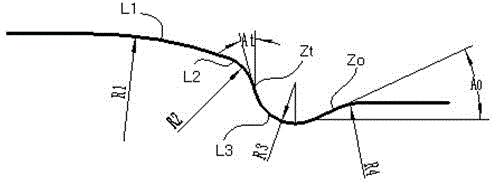

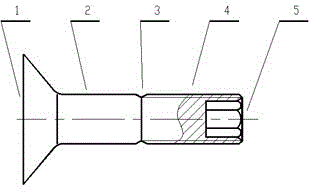

[0026] The present invention will be further elaborated below in conjunction with the accompanying drawings. Such as figure 1 As shown, the present invention provides a lightweight bolt fastener, which is composed of a bolt head 1 , a polished rod section 2 , a transition section 3 and a threaded section 4 . The transition part 3 starts from the large-diameter polished rod section 2 and is connected with the root of the small-diameter threaded section 4 in a transition trend of gradually decreasing outer diameter. In the present invention, the generatrix of the light bolt transition part 3 (that is, the transition line from the proximal end of the maximum clamping length on the polished rod section to the beginning of the complete thread on the threaded section) is designed to be a smooth curve approximately sinusoidal, by the first Arc section L1, second arc section L2, front cone section Zt, third arc section L3, and rear cone section ZO are formed by a smooth transition fr...

Embodiment 2

[0031] The difference between this embodiment and embodiment 1 is that

[0032] The angle between the front cone section or its extension line and a straight line perpendicular to the bolt axis is the front cone section inclination angle At, and its angle range is 24 °; the rear cone section or its extension line is parallel to The included angle between a straight line in the axial direction of the bolt is the inclination angle A0 of the rear cone section, and the angle range thereof is 45°.

Embodiment 3

[0034] The difference between this embodiment and embodiment 1 is that

[0035] The included angle between the front cone section or its extension line and a straight line perpendicular to the bolt axis is the front cone section inclination angle At, and its angle range is 15 °; the rear cone section or its extension line is parallel to The included angle between a straight line in the axial direction of the bolt is the inclination angle A0 of the rear cone section, and the angle range thereof is 25°.

[0036] In summary, the present invention provides four technical measures, so that the inclination angle of the cone section is relatively small, the transition portion is relatively short, the length of the bolt is reduced, the transition portion is a smooth curve approximately sinusoidal, and the structure is more reasonable; the bolt tail The hexagonal plum blossom-shaped wrench hole has a large wrenching torque and relatively short wrench hole, which facilitates installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com