Fault treatment system of numerical control machine tool

A technology of numerical control machine tools and processing systems, applied in the field of numerical control machine tools, can solve problems such as the inability to take control measures for numerical control machine tools, the difficulty of collecting fault characteristics of numerical control machine tools, and the difficulty of determining the types of faults, etc., to achieve accurate and reasonable diagnosis results, improve operating efficiency and enterprise The economic benefits and the effect of reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

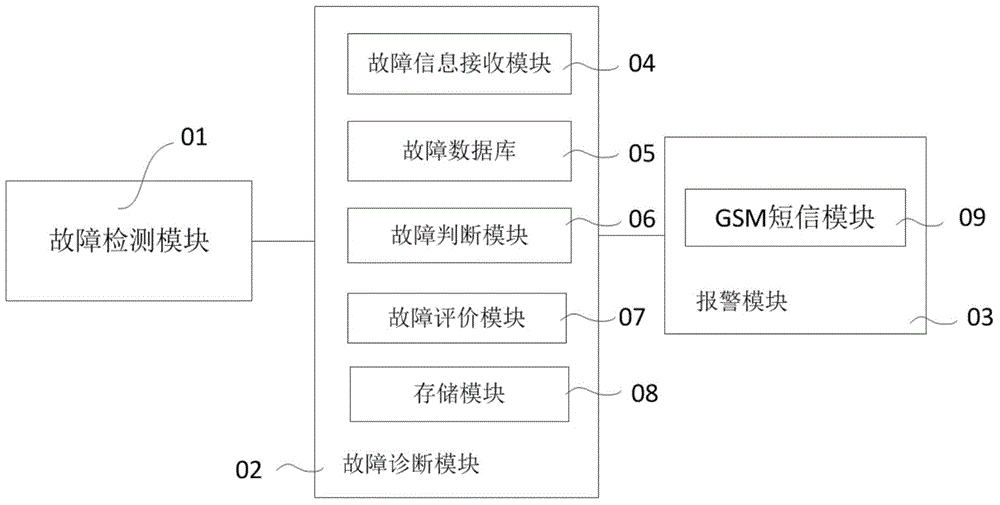

[0022] Such as figure 1 As shown, the CNC machine tool fault processing system of this embodiment includes a fault detection module 01, a fault diagnosis module 02, and an alarm module 03.

[0023] The fault detection module 01 is used to send fault characteristic information to the fault diagnosis module when the CNC machine tool fails. Preferably, the fault detection module 01 in this embodiment is a vibration sensor, a speed sensor, a sound sensor and / or a temperature sensor arranged on a numerically controlled machine tool. In this embodiment, the collected fault characteristic information includes the current status information of the various components of the CNC machine tool and the status information of the machine to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com