Nonwoven fabric bag with handles

A technology of non-woven bags and handles, which is applied in the field of non-woven bags with handles, which can solve the problems of labor and time required for manufacturing, difficulty in purchasing easily, and increased manufacturing costs, so as to achieve reduced manufacturing costs and excellent portability , The effect of shortening the effort and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

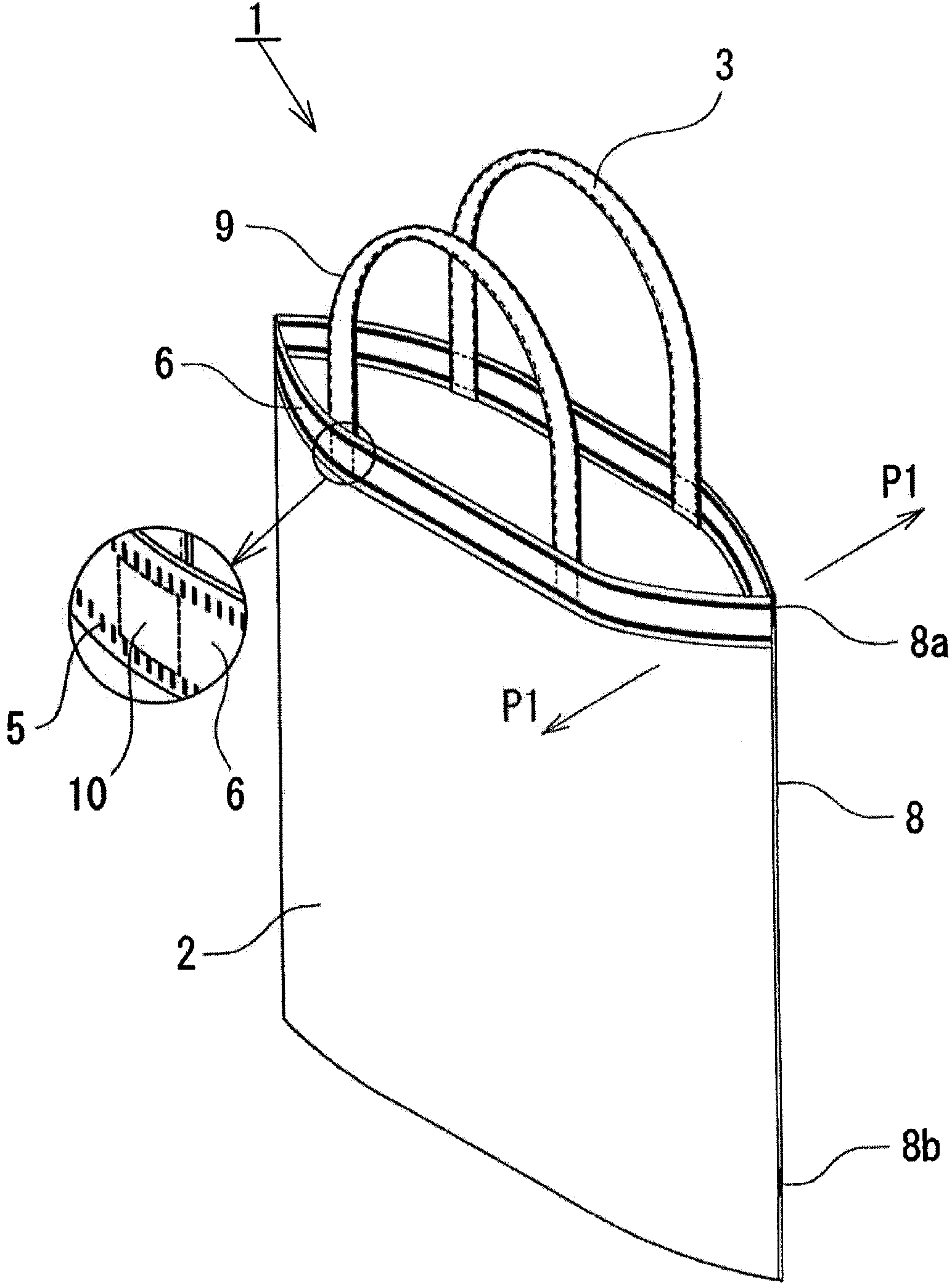

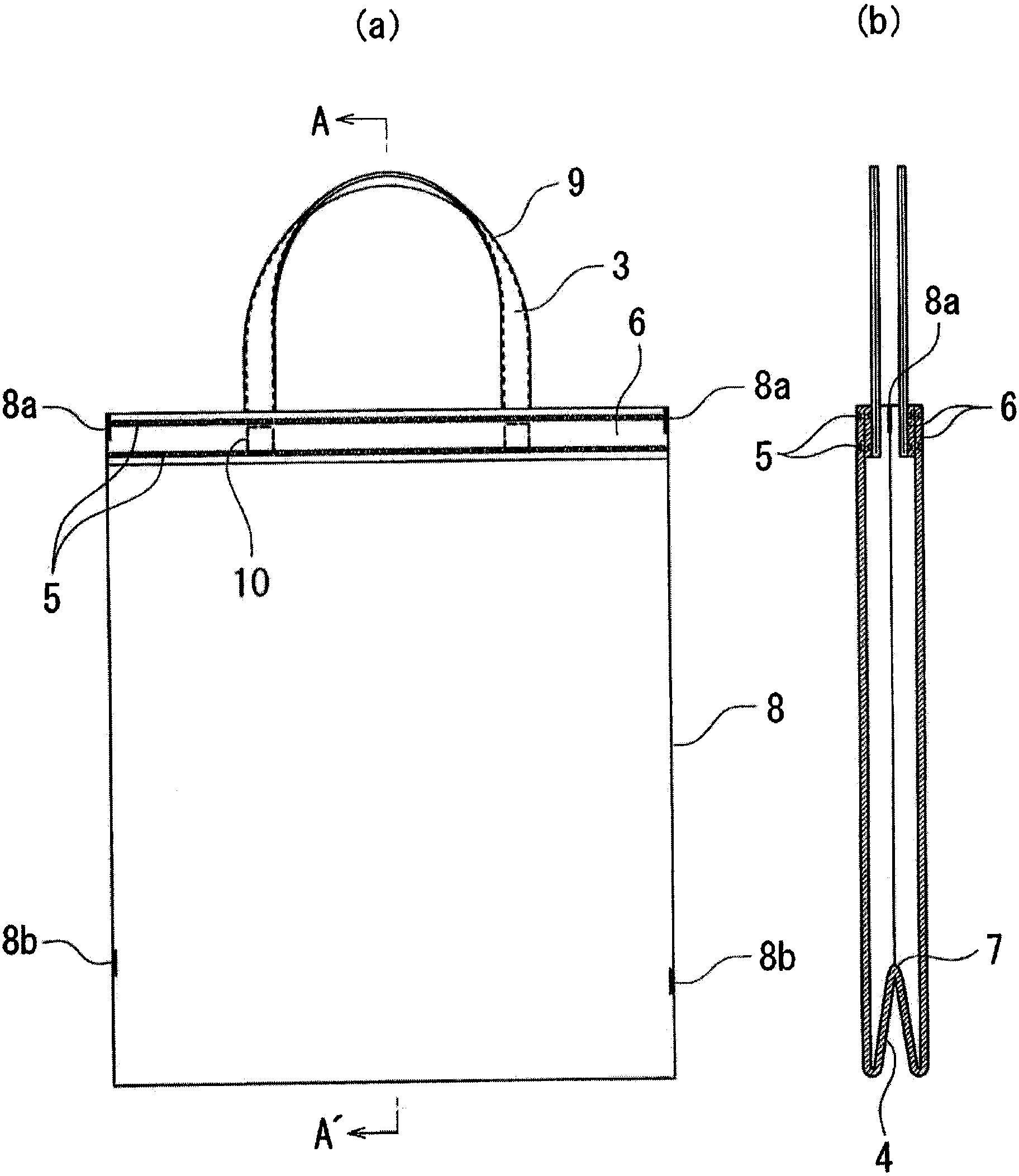

[0082] The non-woven bag 1 with a handle of embodiment 1 is equipped with a bag body 2 and a handle 3 made of polyester yarn or polypropylene yarn (refer to figure 1 ), the bag bottom 4 can be folded (refer to figure 2 ).

[0083] Fold a 76cm×112cm rectangular non-woven fabric sheet in half so that the short sides overlap each other, fold the sheet including its crease 7 inwardly (valley fold) 7.5cm, and seal it by pulse heat (basic condition: heater (a pair of cylinders: each cylinder has a diameter of 0.9mm), heating (sealing) time of 4 seconds, voltage of 220V, and instantaneous current of 45A) The side edges 8 of the bag are bonded together.

[0084] The bag body 2 has a length of 76 cm and a height of 45 cm. The bottom of the bag 4 is approximately elliptical with a minor axis of 15 cm and a major axis of 30 cm. The edge of the opening is bent inward by 3.5 cm, and the distance from the edge of the opening is 0.5 cm and 3.0 cm. Ultrasonic sealing is performed on the tw...

Embodiment 2

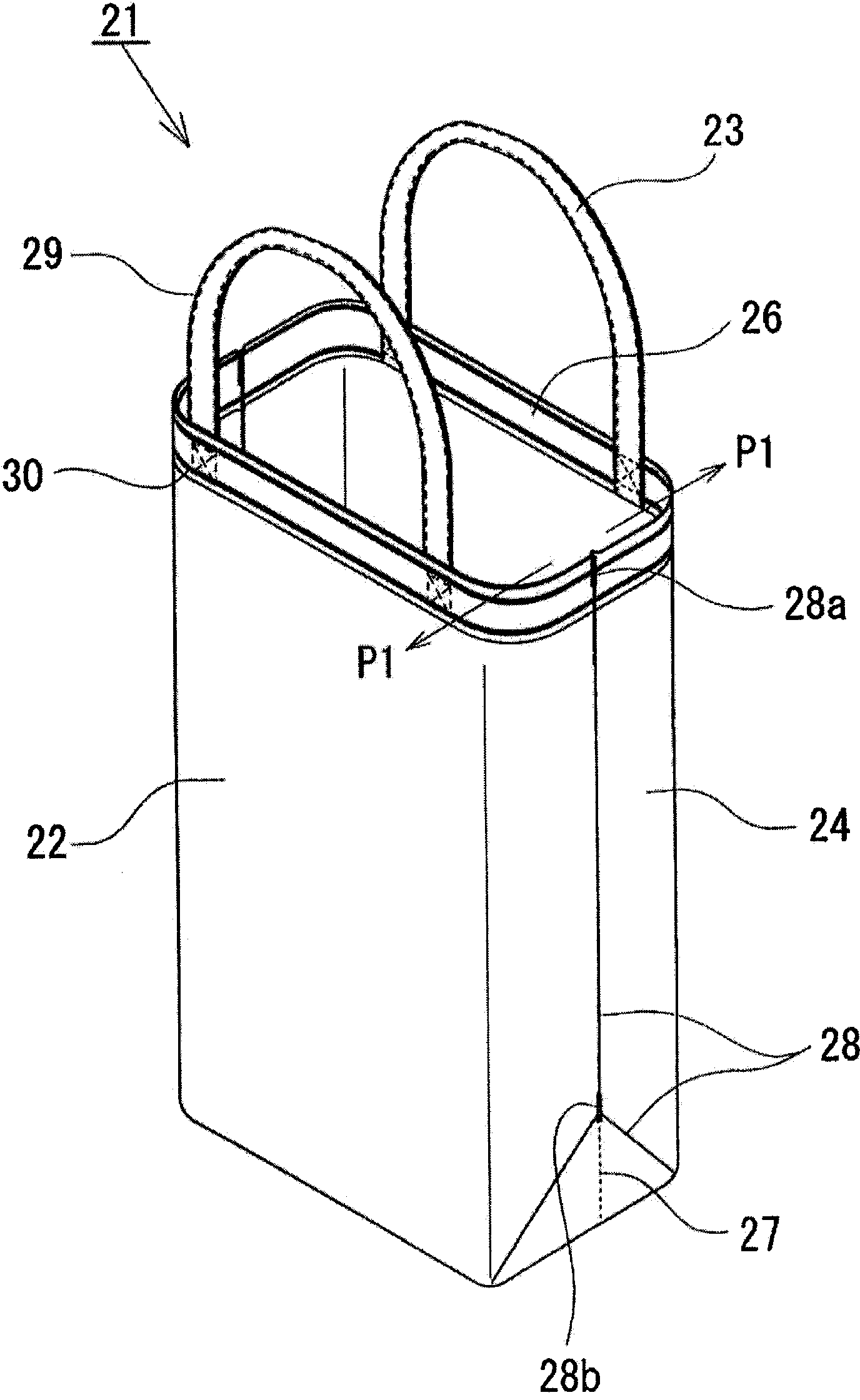

[0088] The non-woven fabric bag 21 with a handle made of non-woven fabric of embodiment 2 is equipped with a bag body 22 and a handle 23 made of polyester yarn or polypropylene yarn (refer to image 3 ), the sides can be folded (see Figure 4 ).

[0089] A rectangular non-woven fabric sheet of 76 cm x 112 cm is folded in half so that the short sides overlap each other, and the sheet including the crease 27 is folded inward by 7 cm and cut off, and then sealed by pulse heat (basic conditions: heater ( A pair of cylinders: the diameter of each cylinder is 0.9mm), the heating (sealing) time is 4 seconds, the voltage is 220V, and the instantaneous current is 45A) to join the side edges 28 of the bag.

[0090] The front and back of the bag body 22 have a width of 22 cm, a left and right side width of 14 cm, and a height of 45 cm. The bag bottom 24 is roughly rectangular in shape. Ultrasonic sealing (basic conditions: voltage 220V, current 1A, speed 4m / min) of the 2 parts in a knu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com