Evaporative crystallization device for extracting ammonium salt by utilizing vapor recompression technique

A steam recompression, evaporation and crystallization technology, applied in evaporation, solution crystallization, evaporator accessories, etc., can solve the problem that the evaporator can no longer provide steam heat source for the preheater, consume energy, etc., to achieve pressure and temperature rise, Guaranteed normal operation, enthalpy increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

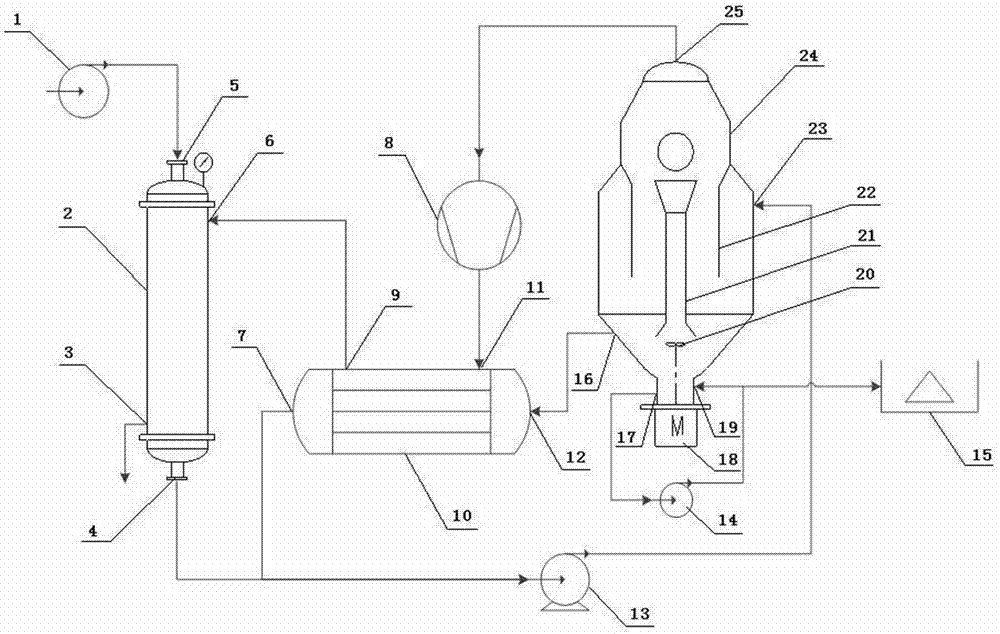

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 Shown, the evaporative crystallization device utilizing vapor recompression technology of the present invention to extract ammonium salt comprises feed pump 1, preheater 2, circulation pump 13, crystallization tank 24, magma pump 14, centrifuge 15, evaporator 10 and Steam compressor 8. The upper part of the preheater 2 has a first solution inlet 5 and a first steam inlet 6 , and the lower part has a first solution outlet 4 and a condensate outlet 3 . The upper part of the crystallization tank 24 has a second solution inlet 23 and a secondary steam outlet 25, and the lower part has a second solution outlet 16, a magma outlet 17 and a magma inlet 19. The evaporator 10 is horizontally arranged with a third solution inlet 12, a third solution outlet 7, a third steam inlet 11 and a third steam outlet 9, and the third steam inlet 11 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com