Silicon wafer micro-crack detection device based on solar cell piece and using method thereof

A technology for solar cells and detection devices, which is applied in measuring devices, optical testing of flaws/defects, and material analysis through optical means. Reduce and other problems, to achieve the effect of strengthening the lighting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

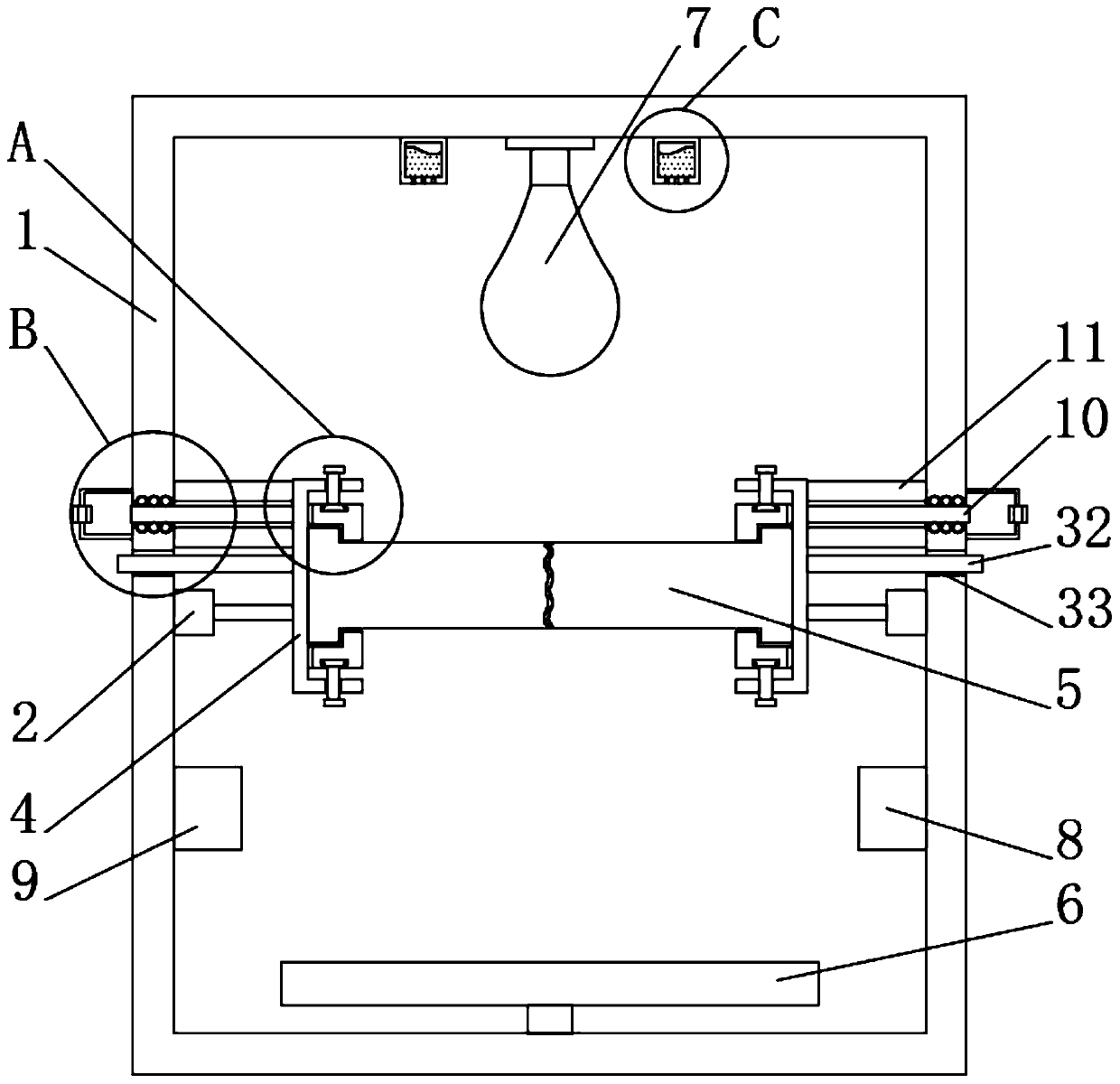

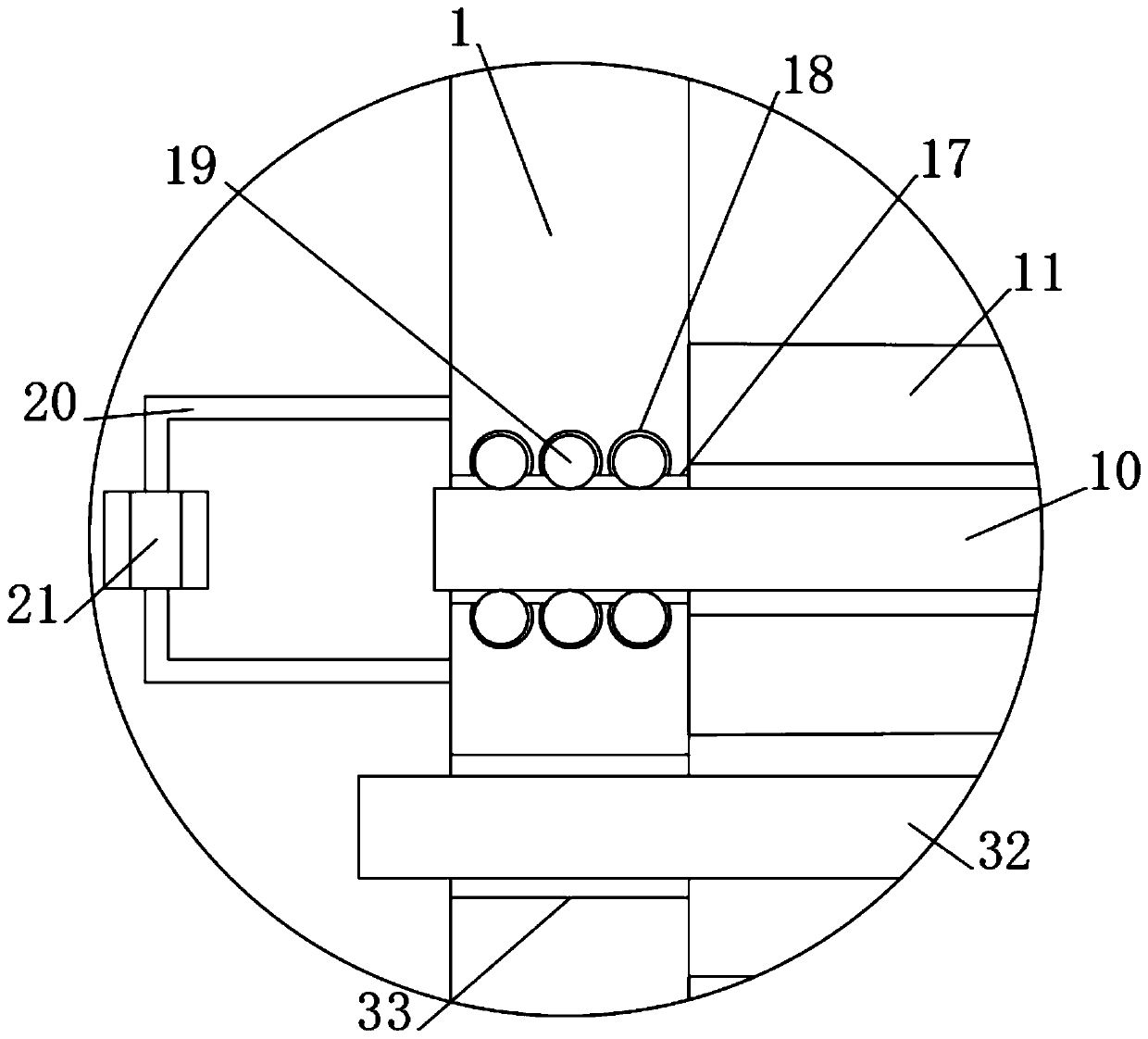

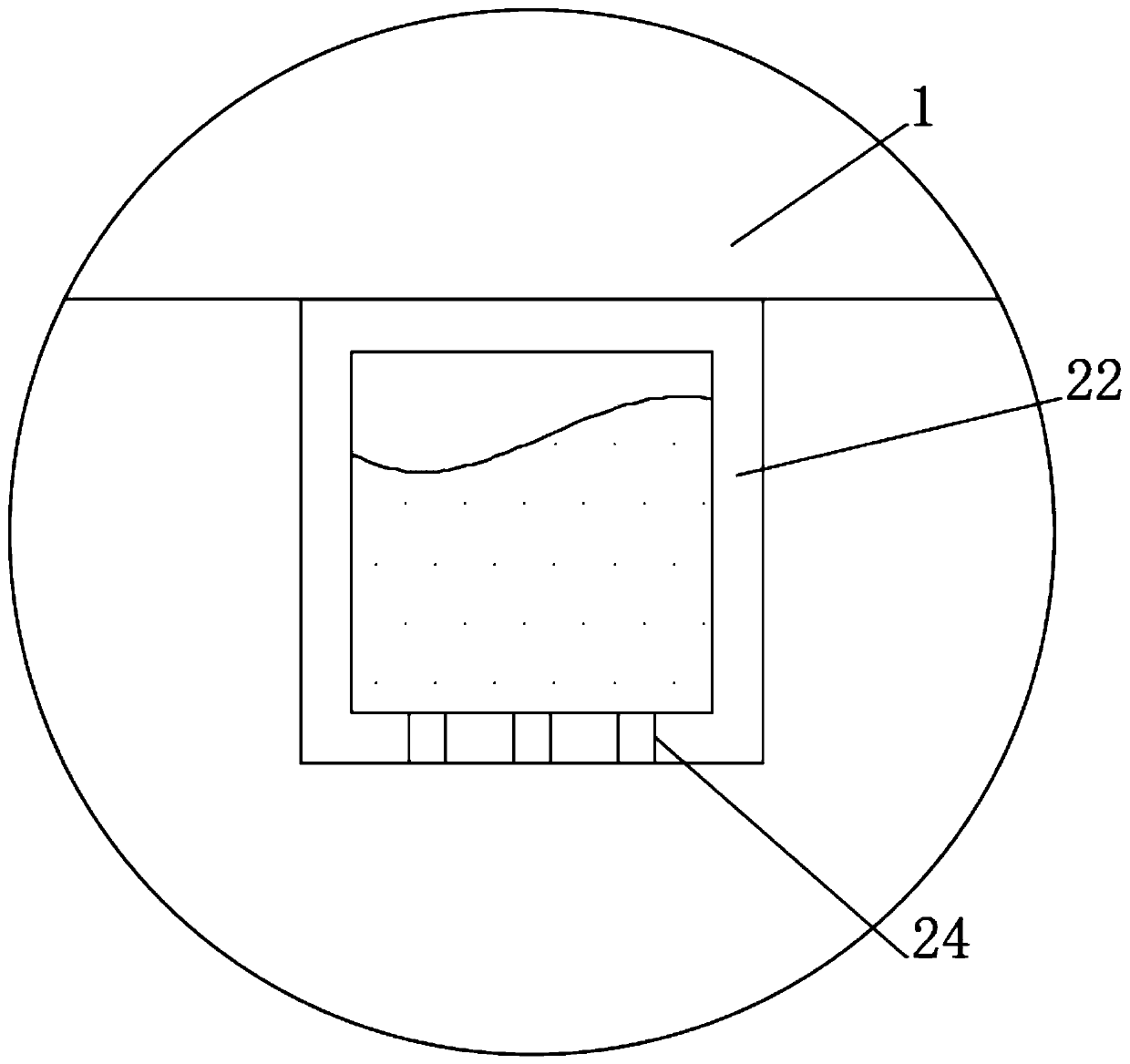

[0036] see Figure 1-2 , a micro-crack detection device based on solar cell silicon wafers, comprising a detection equipment main body 1, cylinders 2 are installed on the left and right inner walls of the detection equipment main body 1, the output ends of the two cylinders 2 are fixedly connected with clamping equipment 4, two A silicon wafer 5 is arranged between the clamping equipment 4, a photoelectric sensor 6 is installed at the inner bottom of the detection equipment main body 1, an LED light 7 is installed on the upper inner wall of the detection equipment main body 1, a power supply 8 is installed on the right inner wall of the detection equipment main body 1, and the detection equipment A controller 9 is installed on the left inner wall of the main body 1, a movable plate 10 is fixedly connected to the ends of the two holding devices 4 away from each other, an annular bag 11 is fixedly connected between the holding device 4 and the inner wall of the main body 1 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com