Solder strip of double-sided reflective structure and manufacturing method thereof

A technology of reflective structure and manufacturing method, applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of no reflective function and low power on the back of double-sided modules, and achieve the effect of reducing spacing, improving conversion efficiency, and increasing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

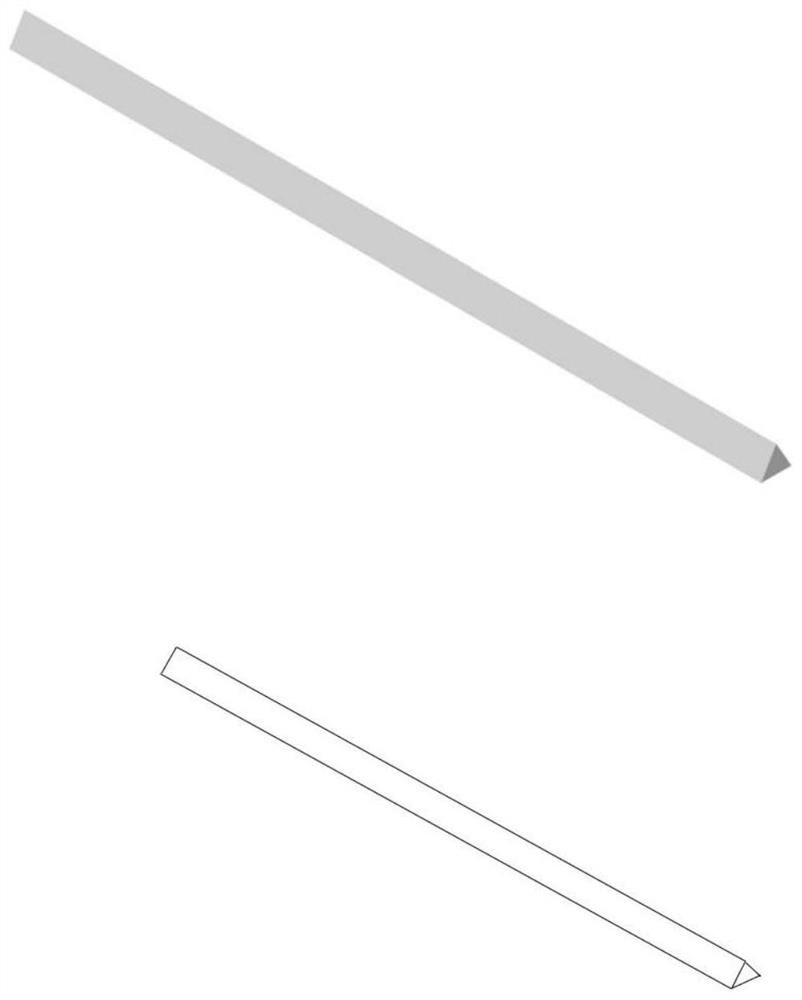

[0027] Conventional reflective ribbon such as figure 1 As shown, the cross-section is triangular. Compared with the flat ribbon, when the sun shines on the surface of the triangular ribbon, the triangular ribbon can reflect most of the light to the surface of the battery sheet, thereby increasing the battery life. The use of light, and the flat ribbon, when the sun shines on the surface of the ribbon, the light will be reflected out of the module, and the light will not be effectively used.

[0028] In the process of making photovoltaic modules, the role of the ribbon is to connect the cells together to form a conductive current loop. Therefore, the ribbon needs to be connected to the positive and negative electrodes of the battery. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com