Gas-liquid-solid three-phase separator

A three-phase separator, gas-liquid-solid technology, applied in the direction of sedimentation separation, separation method, dispersed particle separation, etc., can solve the problem of ineffective collection of liquid-solid-liquid separation, large fluctuation of gas-liquid-solid, poor solid-liquid separation effect, etc. problem, achieve the effect of preventing crushing, improving separation effect and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

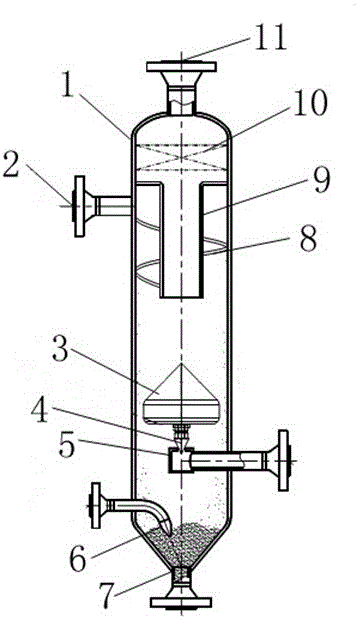

[0052] The gas-liquid-solid three-phase separator of this embodiment includes a feed inlet, a gas discharge end and a solid-liquid discharge end, and the feed inlet, gas and solid-liquid discharge ends are all arranged on the cylinder; the feed inlet is arranged tangentially On the cylinder body; the gas discharge end includes a gas riser and a gas outlet, the gas riser is connected to the gas outlet, and a wire mesh mist catcher is also arranged between the gas riser and the gas outlet, and the outer wall of the gas riser is provided along the The outer wall of the gas riser pipe spirals downward to the spiral guide plate, and the spiral guide plate communicates with the feed inlet, so that the inner wall of the cylinder, the outer wall of the gas riser pipe and the spiral guide plate together form a spiral channel.

[0053] The solid-liquid discharge end includes a liquid outlet, a sand discharge port and a liquid discharge valve assembly; the sand discharge port is set at th...

Embodiment 2

[0056] The gas-liquid-solid three-phase separator of this embodiment includes a feed inlet, a gas discharge end and a solid-liquid discharge end, and the feed inlet, gas and solid-liquid discharge ends are all arranged on the cylinder; the feed inlet is arranged tangentially On the cylinder body; the gas discharge end includes a gas riser and a gas outlet, the gas riser is connected to the gas outlet, and a wire mesh mist catcher is also arranged between the gas riser and the gas outlet, and the outer wall of the gas riser is provided along the The spiral guide plate spirals downwards on the outer wall of the gas riser tube. There is a gap between the spiral guide plate and the inner wall of the cylinder. form a spiral channel.

[0057] The solid-liquid discharge end includes a liquid outlet, a sand discharge port and a liquid discharge valve assembly; the sand discharge port is set at the bottom of the cylinder, the liquid outlet is located at the upper end of the sand discha...

Embodiment 3

[0060] The gas-liquid-solid three-phase separator of this embodiment includes a feed inlet, a gas discharge end and a solid-liquid discharge end, and the feed inlet, gas and solid-liquid discharge ends are all arranged on the cylinder; the feed inlet is arranged tangentially On the cylinder body; the gas discharge end includes a gas riser and a gas outlet, the gas riser is connected to the gas outlet, and a wire mesh mist catcher is also arranged between the gas riser and the gas outlet, and the outer wall of the gas riser is provided along the The spiral guide plate spirals downwards on the outer wall of the gas riser tube. There is a gap between the spiral guide plate and the inner wall of the cylinder. form a spiral channel.

[0061] The solid-liquid discharge end includes a liquid outlet, a sand discharge port and a liquid discharge valve assembly; the sand discharge port is set at the bottom of the cylinder, the liquid outlet is located at the upper end of the sand discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com