Rotary push type casing cleaning brush

A cleaning brush and push-type technology, which is applied in the direction of brushes, bristles, and cleaning hollow objects, etc., can solve the problems of unclean cleaning of casings, easily damaged casings, and difficulty in meeting food standards, so as to avoid dead ends, corrosion, The effect of prolonging the useful life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order for those skilled in the art to better understand the technical solutions of the present invention, the present invention is further described below with reference to the accompanying drawings.

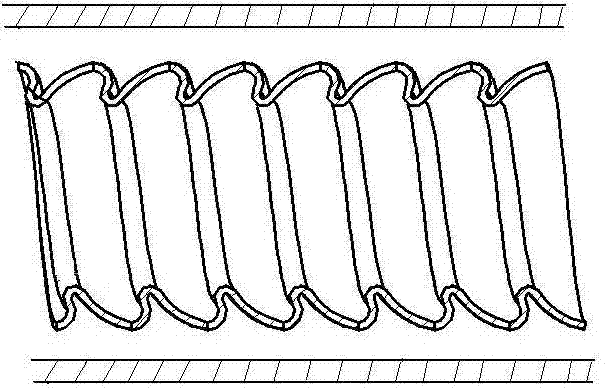

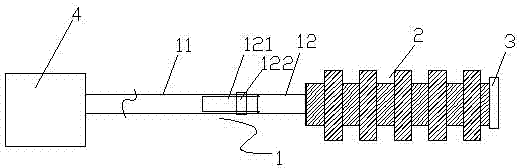

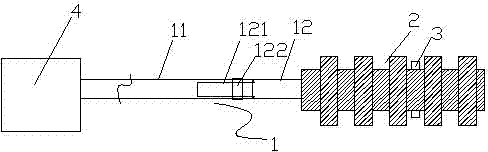

[0014] specific examples, such as Figures 1~3 As shown, the present invention provides a rotary push-type casing cleaning brush, suitable for figure 1 Cleaning of cannulae of the type shown. A rotary push-type casing cleaning brush includes a hose 1 for transmitting torque, the hose 1 includes a torque tube 11 and a flexible shaft 12, the torque tube 11 and the flexible shaft 12 are detachably connected, and the specific connection method is a plug-in connection, The front end of the flexible shaft 12 is provided with bristles 2 for cleaning the inner wall of the casing. The bristles include long bristles 21 and short bristles 22 that are threadedly distributed at the front end of the hose and are suitable for cleaning the inner wall of the casing. When the cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com