Automobile lamellar product

A layered and product technology, applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of insufficient rigidity, easy to break failure, poor impact resistance, etc., and achieve excellent impact absorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

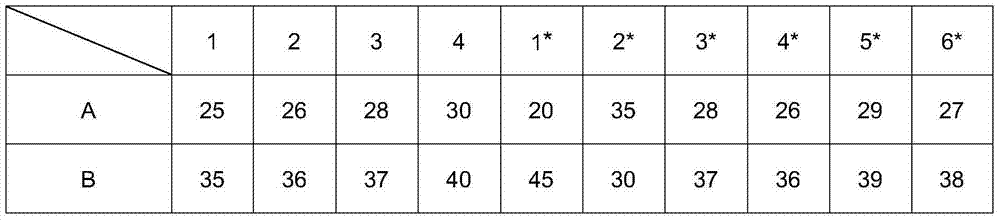

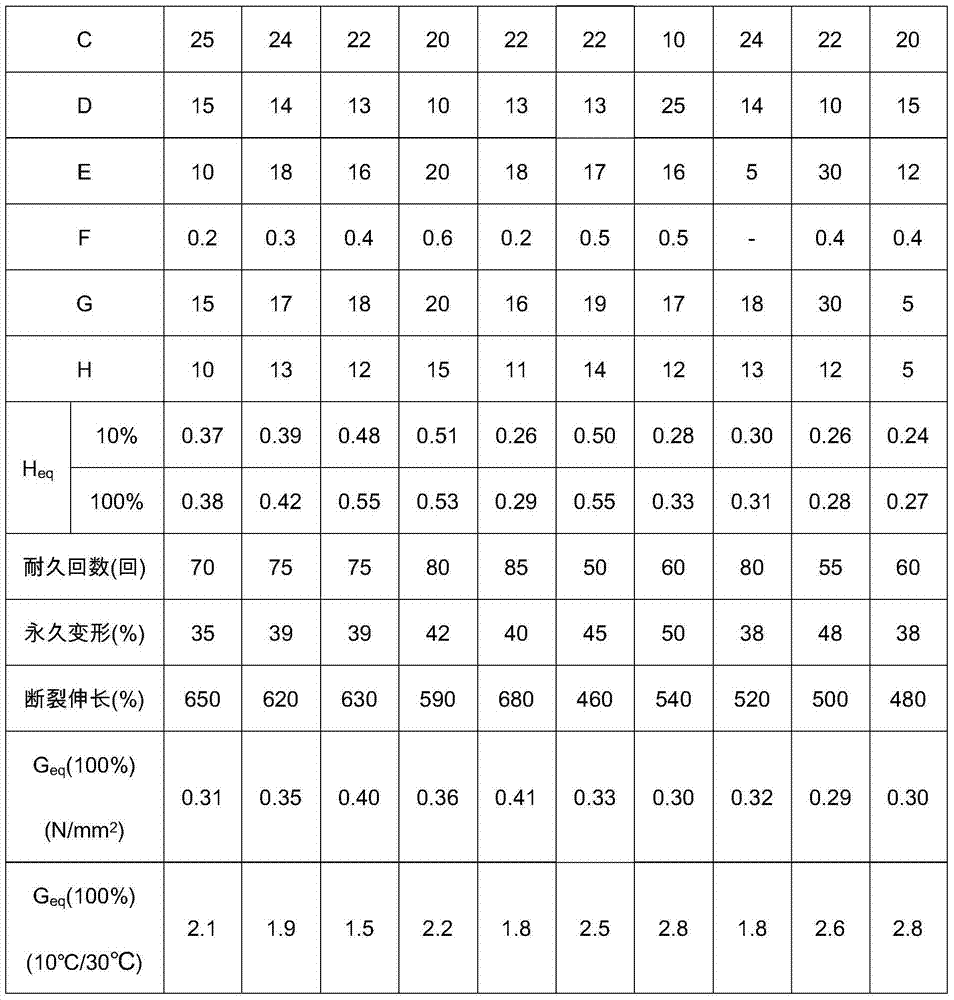

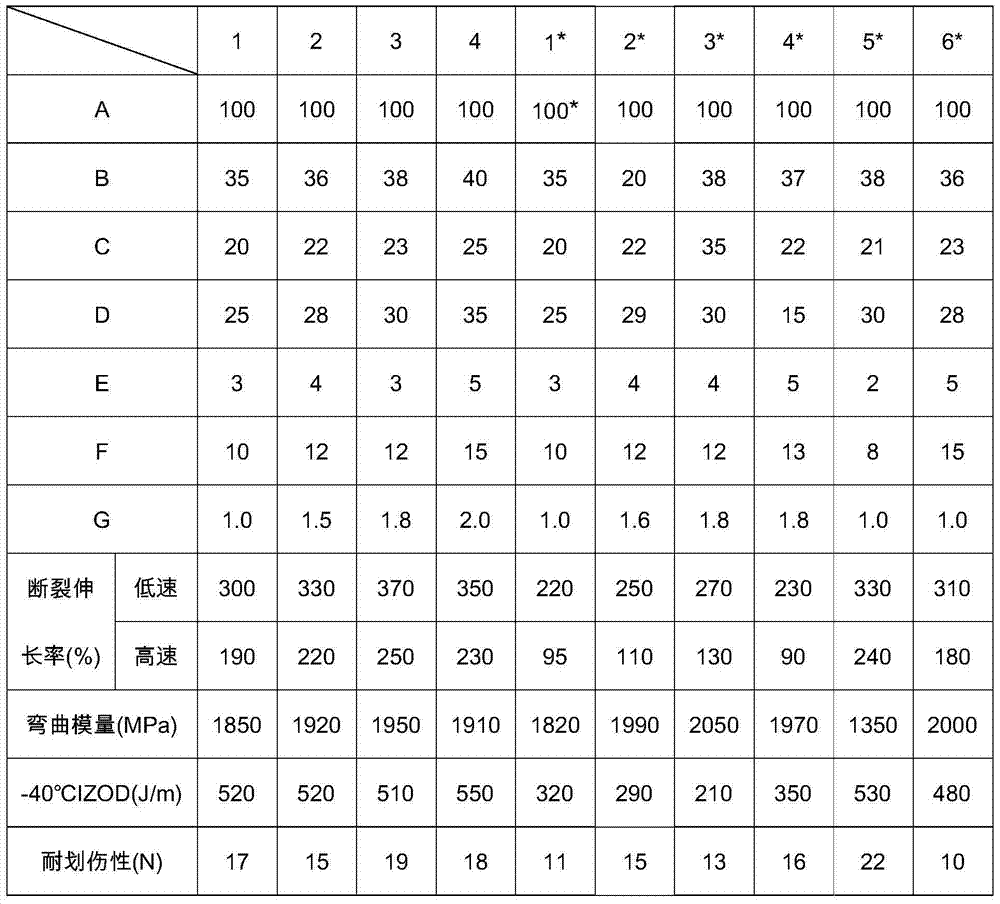

[0016] According to the distribution ratio of each group given in Table 1, ingredients are prepared and dried to 100℃ for standby;

[0017] Step 1: First, mix the polystyrene-polyisobutylene block copolymer, polystyrene-polyisobutylene-polystyrene block copolymer and chlorinated butyl rubber, and then add half of the inorganic filler and hydrogenated petroleum Resin and paraffin oil are one-third of the proportion, and then melt-mixed in a plastic mill, the mixing temperature is 150°C, and the mixing time is 3 minutes;

[0018] Step 2: Then add dicumyl peroxide for further melt mixing and crosslinking, and the mixing time is 5 minutes;

[0019] Step 3: Add the homopolypropylene resin and the remaining inorganic fillers to the mixed product, increase the temperature of the plastic mill to 180°C, melt and mix for 10 minutes, and take out the obtained mixed product;

[0020] Step four: heating the mixed product of step three to 180° C. and hot-press forming under a pressure of 6 MPa to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com