Plastic material and preparation method thereof

A technology of plastic materials and formulations, applied in the field of plastic materials, can solve problems such as uneven foaming, achieve good foaming effects, improve reactivity, and protect body joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

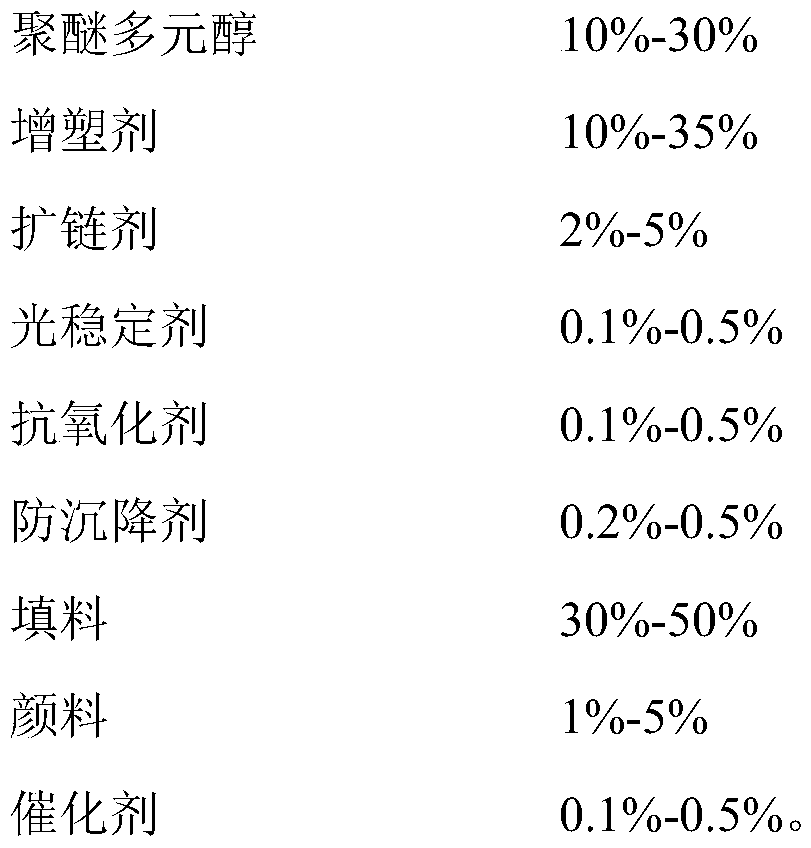

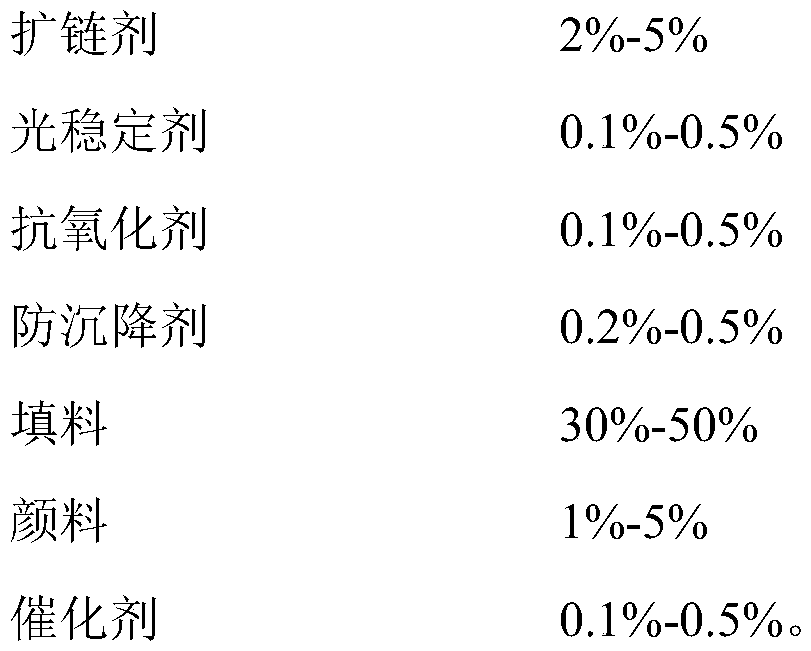

[0028] A plastic material, prepared by mixed reaction of component A containing polyether polyol and component B containing isocyanate; wherein, the raw material composition and weight percentage of component A are:

[0029]

[0030]

[0031] The raw material composition and weight percent of B component are:

[0032] Mixed polyether polyol 60%-75%

[0033] Diphenylmethane diisocyanate 25%-40%.

[0034] This kind of catalyst is a compound catalyst of organic amine catalyst and metal catalyst, which can improve the reaction activity and speed up the reaction rate, and at the same time, it can react to produce a pore structure, so that the plastic material has excellent performance.

[0035] The preparation method of above-mentioned plastic material, comprises the following steps:

[0036] (1) The preparation method of component A containing polyether polyol: according to the above raw materials, according to their weight ratio, first add liquid materials such as polyeth...

Embodiment 2

[0040] (1) Preparation of component A containing polyether polyol: According to the formula amount, first add liquid materials such as polyether polyol and plasticizer, start stirring, and then add chain extender, light stabilizer, antioxidant, anti-settling agent , fillers and pigments are added according to weight percentage, stirred evenly, and heated to 70-80°C, stirred for 1 hour, then cooled to below 60°C, added catalyst, stirred for 0.5 hour, and then grinded the above materials with a grinder.

[0041] (2) The preparation method of component B containing isocyanate: According to the formula amount, first add polyether polyol, start stirring, heating device, when the temperature rises to 75-80°C, vacuumize and dehydrate and degas for 1 hour. Then lower the temperature to below 60°C, add diphenylmethane diisocyanate, and react at 80-85°C for 3 hours.

[0042] (3) The application and preparation method of a catalyst in plastic materials; the A component containing polyeth...

Embodiment 3

[0047] A plastic material, comprising a component A containing polyether polyol and a component B containing isocyanate, wherein the component A is composed of the following components in weight percentage: 28% polyether polyol, 10% plasticizer, 5% chain agent, 0.5% light stabilizer, 0.5% antioxidant, 0.5% anti-settling agent, 50% filler, 5% pigment, 0.5% catalyst; B component is composed of the following components by weight percentage: mixed polyether polyol 60%, diphenylmethane diisocyanate 40%; the catalyst is a complex product of an organic amine catalyst and a metal catalyst.

[0048] The preparation method of above-mentioned plastic material, comprises the following steps:

[0049] 1) Mix the polyether polyol and plasticizer in the formulated amount and stir, then add the chain extender, light stabilizer, antioxidant, anti-settling agent, filler, and pigment in the formulated amount, stir evenly, and heat up to 70 ℃, stirred for 1 hour, then lowered the temperature to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com