Polyolefin resin foam sheet and method for producing same

A polyolefin-based resin and polyethylene-based resin technology, applied in the field of polyolefin-based resin foam sheets, can solve the problems of reduced impact absorption and achieve good impact absorption and good reprocessing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

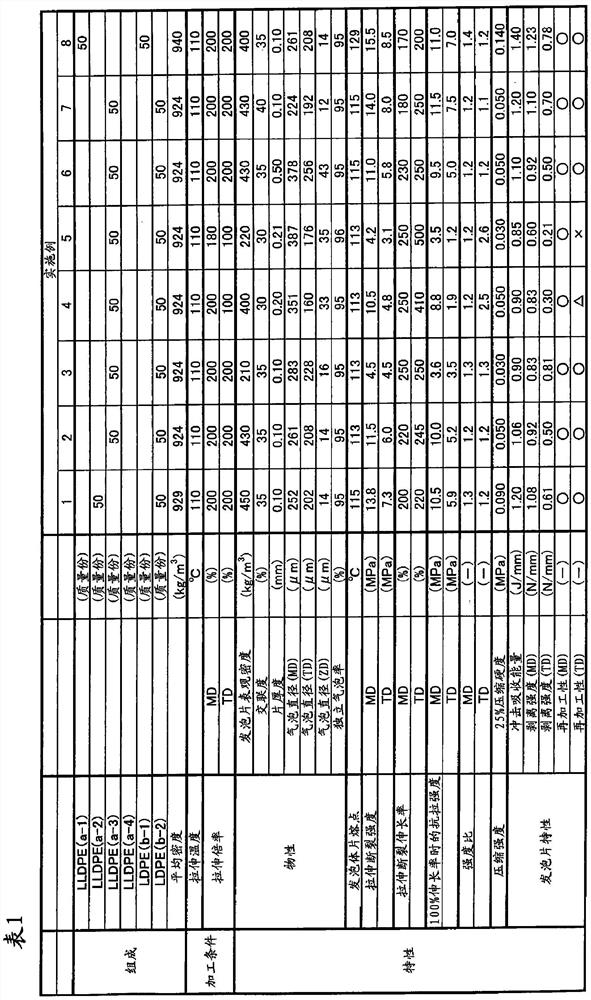

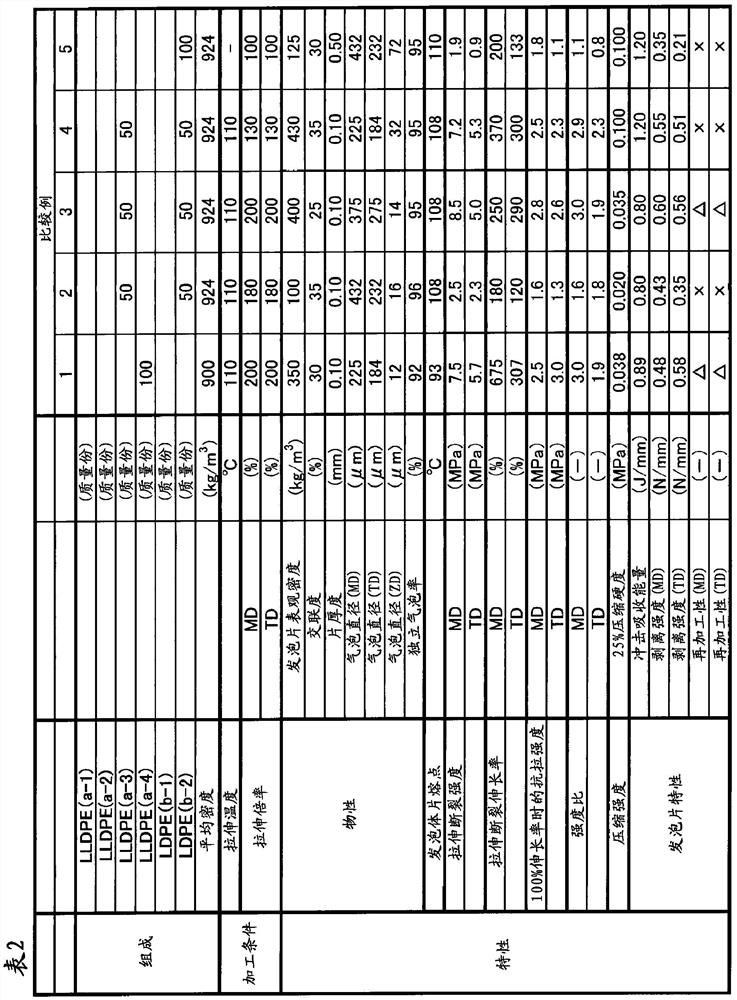

Embodiment 1

[0095] 50 parts by mass of LLDPE (a-2) and 50 parts by mass of LDPE (b-2) as a polyolefin resin, 2.5 parts by mass of azodicarbonamide as a thermally decomposable foaming agent, and 0.5 parts by mass of a phenolic antioxidant The parts were supplied to an extruder and melt-kneaded at 130°C. The foamable composition obtained by kneading the supplied components was extruded from an extruder to obtain a foamable sheet having a thickness of 0.50 mm. Next, the foamable sheet was irradiated with electron beams at 7.5 Mrad from both sides, and the foamable sheet was crosslinked to obtain a crosslinked foamable sheet. The crosslinked foamable sheet was continuously fed into a foaming furnace whose upper surface was maintained at 240° C. by an infrared heater and a lower surface by a salt bath, and the sheet was heated and foamed to obtain a foamed sheet. The melting point of the foamed sheet was 115°C. Next, after being temporarily cooled, the foam sheet was obtained by stretching a...

Embodiment 2

[0097] 50 parts by mass of LLDPE (a-3) and 50 parts by mass of LDPE (b-2) as a polyolefin resin, 2.5 parts by mass of azodicarbonamide as a thermally decomposable foaming agent, and 0.5 parts by mass of a phenolic antioxidant The parts were supplied to an extruder and melt-kneaded at 130°C. In addition, the conditions of the method described in Example 1 were followed, and a foamed sheet was obtained by stretching at the stretching ratios in the MD and TD directions described in Table 1. The melting point of the foamed sheet was 113°C. The obtained foam sheet was evaluated according to the above-mentioned evaluation method. The results are shown in Table 1.

Embodiment 3

[0099] 50 parts by mass of LLDPE (a-3) and 50 parts by mass of LDPE (b-2) as a polyolefin resin, 4.5 parts by mass of azodicarbonamide as a thermally decomposable foaming agent, and 0.5 parts by mass of a phenolic antioxidant The parts were supplied to an extruder and melt-kneaded at 130°C. The foamable composition obtained by kneading the supplied components was extruded from an extruder to obtain a foamable sheet having a thickness of 0.50 mm. Others were subjected to electron beam irradiation and foaming according to the conditions of the method described in Example 1, and stretched at the stretching ratios in the MD and TD directions described in Table 1 to obtain a foamed sheet. The melting point of the foamed sheet was 113°C. The obtained foam sheet was evaluated according to the above-mentioned evaluation method. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com