A free-fall winch braking device applied to a dynamic compaction machine

A technology of free fall and braking device, applied in the direction of hoisting device, brake type, brake components, etc., can solve the problem of difficulty in manufacturing the hoist, and achieve the effects of easy heat dissipation, compact overall structure, and increased braking force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

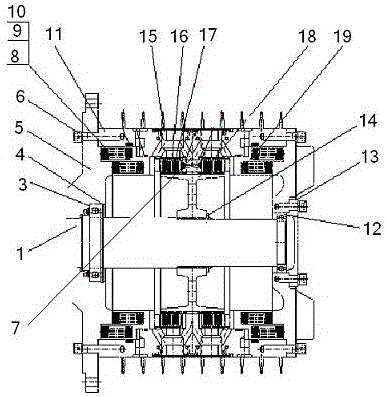

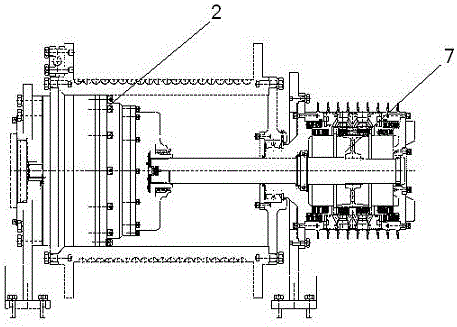

[0015] The present invention will be described in detail below in conjunction with the drawings and embodiments.

[0016] The present invention is a free-falling hoist brake device applied to a dynamic compaction machine, comprising: a free-falling dynamic compaction machine hoist 2, a brake 7; the inner brake pad 17, the outer brake pad 16, and the bearing I3 of the brake 7 Bearing Ⅱ12, circlip Ⅰ4, and circlip Ⅱ14 are arranged on both sides. This arrangement can increase the braking torque by two times. Compared with the one-sided arrangement, the diameter of the same braking torque is greatly reduced. A series of problems caused by the excessively large diameter of the brake pad; the transmission shaft 1 is radially supported by the bearing Ⅰ3 and the bearing Ⅱ12, and the elastic retaining ring Ⅰ4 is stuck in the groove of the supporting seat 5; the spline sleeve 18 is connected with the inner spline Drive shaft 1 is connected; circlip Ⅱ14 is stuck in the slot of drive shaft 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com