System for reusing purified dilute acid

A technology of dilute acid, purification and recycling, which is applied in the field of dilute acid purification and reuse system, can solve the problems of difficulty in work, waste of water resources, and water resources cannot be recycled, and achieves the effect of increasing economic benefits and reducing waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

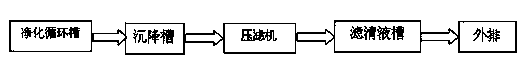

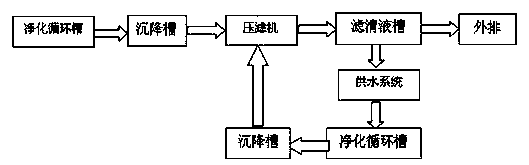

[0012] Such as figure 2 As shown, a purification dilute acid recycling system includes a purification circulation tank, a settling tank, a filter press, and a filtrate tank. It is characterized in that it also includes a water supply system, and the smelting flue gas is cooled and purified in the purification circulation tank. When dilute acid is produced, the dilute acid settles after being neutralized with milk of lime in the settling tank, and then enters the filter press to filter into a filter cake, and the filtrate filtered out of the filter press enters the filtrate tank ; At the back of the filtrate tank, add an anti-corrosion tower-free water supply system to allow the filtered water after pressure filtration to return to the purification circulation tank; the tower-free water supply system is used to supplement tap water to reduce the concentration of dilute acid, so that It will not lead to saturation of the circulating fluid concentration. The towerless water sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com