Control method for separating cyclopentadiene from C5 fraction by utilizing dimerization method

A technology for cyclopentadiene and carbon five fractions, which is applied in chemical instruments and methods, purification/separation of hydrocarbons, hydrocarbons, etc., and can solve problems such as difficulty in obtaining optimal reaction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

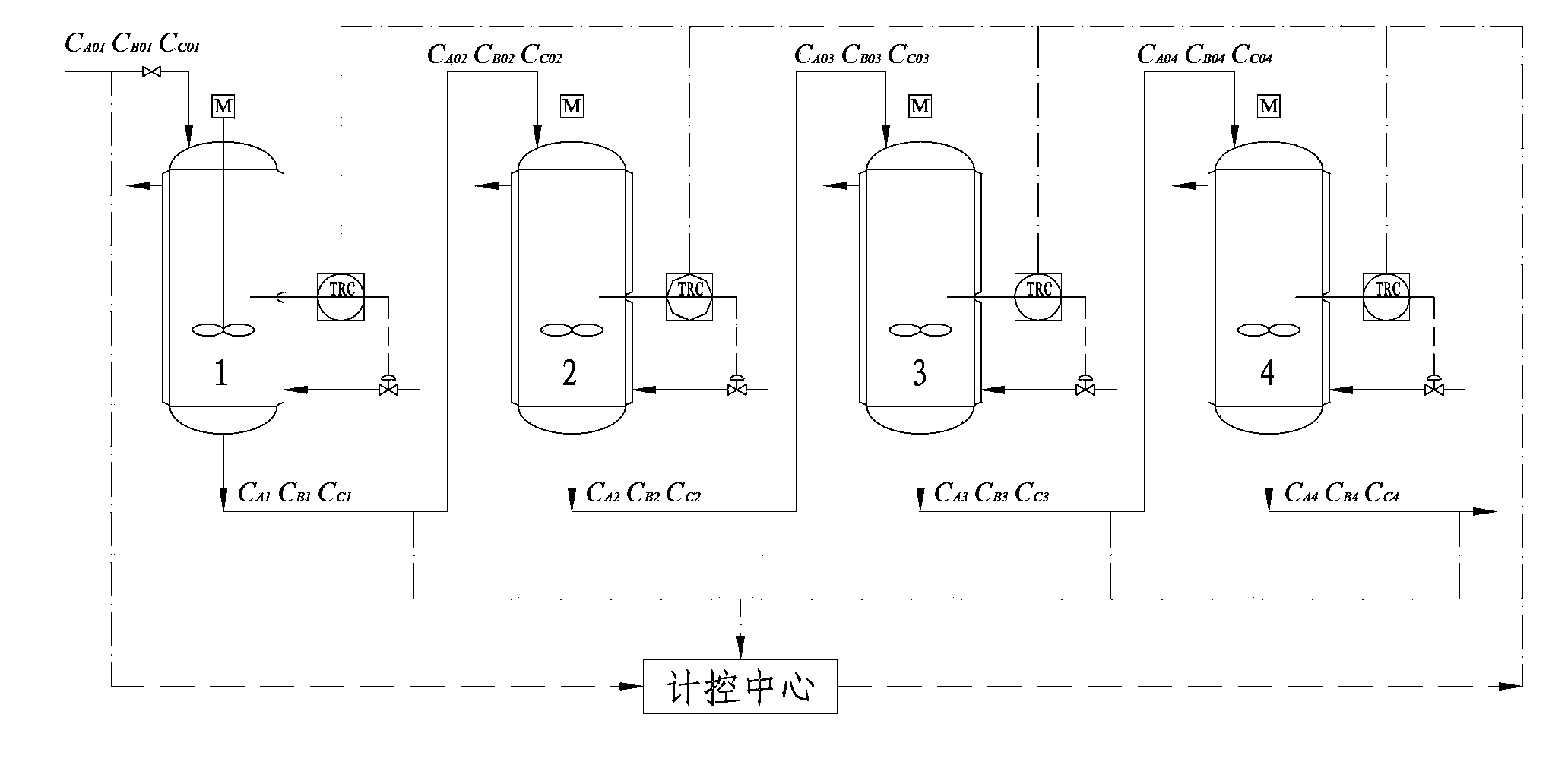

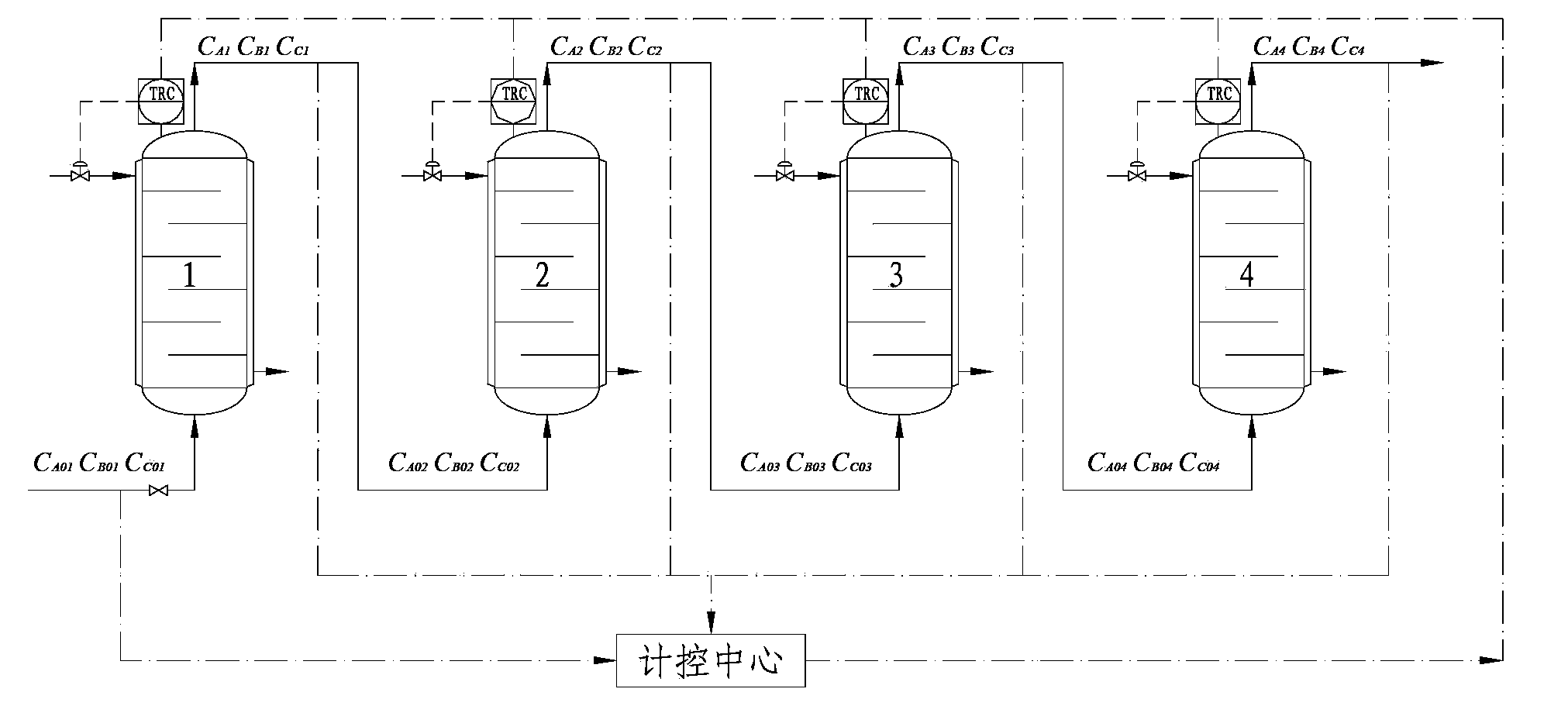

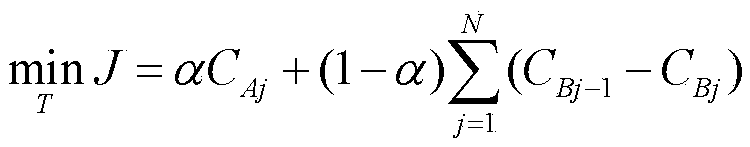

Method used

Image

Examples

Embodiment 1

[0047] The total C5 feed is 165.148 kmol / h, a total of 11,424 kg / h, of which

[0048] Cyclopentadiene 50.183kmol / h

[0049] Isoprene 49.893 kmol / h

[0050] Dicyclopentadiene 0.000 kmol / h

[0051] Three-stage CSTR reactor is used, each reactor has an effective volume of 20m 3 , Volume flow 17.85 m 3 / h, the residence time per kettle is 1.120 hours. The optimized control results are shown in Table 1.

[0052] Table 1. Optimization results of cyclopentadiene dimerization in CSTR reactor

[0053]

Embodiment 2

[0055] The total carbon five feed is 270.957 kmol / h, totaling 18750kg / h, of which

[0056] Cyclopentadiene 75.922 kmol / h

[0057] Isoprene 73.267 kmol / h

[0058] Dicyclopentadiene 2.168 kmol / h

[0059] Adopt 4 PFR reactors, each reactor has an effective volume of 32 m 3 , Volume flow 29.28 m 3 / h, the residence time per kettle is 1.093 hours. The optimized control results are shown in Table 2.

[0060] Table 2. Optimization results of cyclopentadiene dimerization in PFR reactor

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com