Preparation method of CuO/CoTiO3 composite air-sensitive film

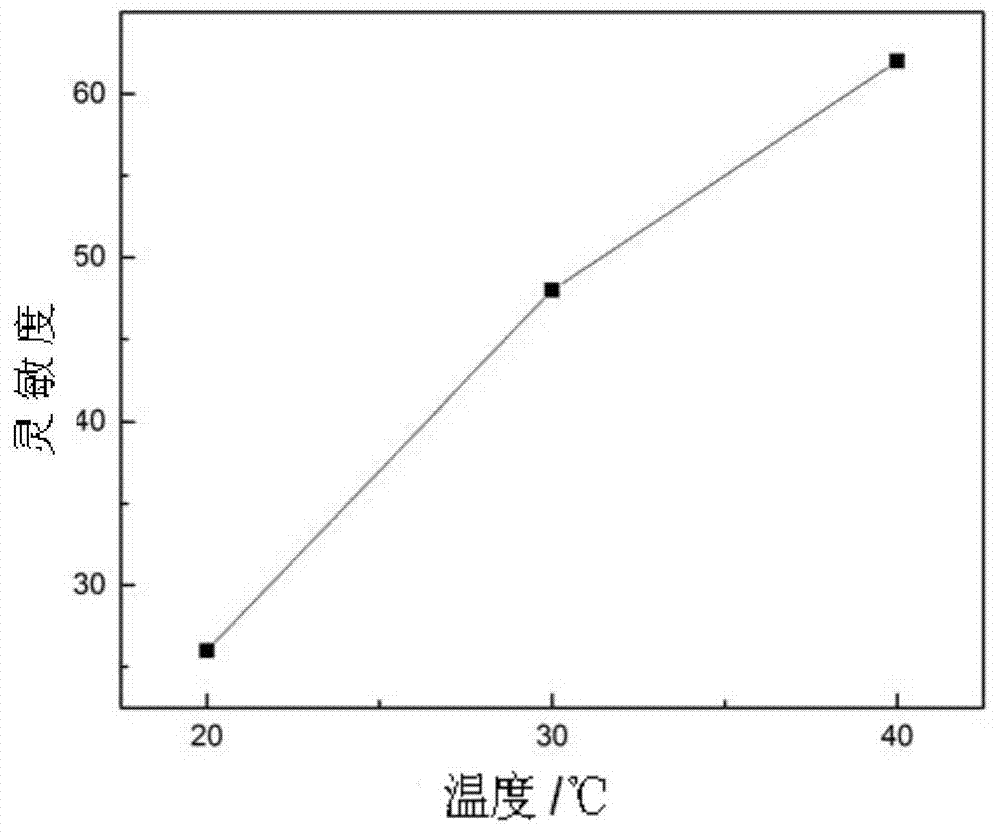

A thin-film and gas-sensing technology, which is applied in the field of preparation of CuO/CoTiO3 composite gas-sensing thin film, can solve the problem of high working temperature of the sensor, and achieve the effects of improving sensitivity, lowering working temperature and uniform distribution of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1) To analyze pure TiO 2 and Co 3 o 4 As raw material, mixed with binder respectively, pre-fired at 50MPa, 200°C to prepare TiO 2 Target and Co 3 o 4 target, and the TiO 2 Target and Co 3 o 4 Put the target material into the two RF target positions of the magnetron sputtering apparatus respectively, and put the Cu target with a purity of 99.99% into the DC sputtering target position;

[0017] 2) Put the clean Si substrate on the coating sample stage of the magnetron sputtering instrument, install a baffle between the target and the substrate of the magnetron sputtering instrument, and pump the coating chamber and the sample chamber through the vacuum system Vacuum, when the vacuum degree reaches 1.0×10 -4 At Pa, the coating chamber is fed with Ar gas, and the Ar gas flow is controlled at 10sccm-30sccm, so that the pressure in the coating chamber and the sample chamber is 0.2Pa;

[0018] The Si substrate was first ultrasonically cleaned in absolute ethanol for 1...

Embodiment 2

[0022] 1) To analyze pure TiO 2 and Co 3 o 4 As raw material, mixed with binder respectively, pre-fired at 80MPa, 500℃ to prepare TiO 2 Target and Co 3 o 4 target, and the TiO 2 Target and Co 3 o 4 The target material is placed in two radio frequency target positions of the magnetron sputtering apparatus, and the Cu target with a purity of 99.99% is placed in the DC sputtering target position;

[0023] 2) Put the clean Si substrate on the coating sample stage of the magnetron sputtering instrument, install a baffle between the target and the substrate of the magnetron sputtering instrument, and pump the coating chamber and the sample chamber through the vacuum system Vacuum, when the vacuum degree reaches 5×10 -4At Pa, the coating chamber is fed with Ar gas, and the Ar gas flow rate is controlled at 10sccm-30sccm, so that the pressure in the coating chamber and the sample chamber is 1Pa;

[0024] The Si substrate was first ultrasonically cleaned in absolute ethanol fo...

Embodiment 3

[0027] 1) To analyze pure TiO 2 and Co 3 o 4 As raw material, mixed with binder respectively, pre-fired at 100MPa, 700°C to prepare TiO 2 Target and Co 3 o 4 target, and the TiO 2 Target and Co 3 o 4 Put the target material into the two RF target positions of the magnetron sputtering apparatus respectively, and put the Cu target with a purity of 99.99% into the DC sputtering target position;

[0028] 2) Put the clean Si substrate on the coating sample stage of the magnetron sputtering instrument, install a baffle between the target and the substrate of the magnetron sputtering instrument, and pump the coating chamber and the sample chamber through the vacuum system Vacuum, when the vacuum degree reaches 9.9×10 -4 At Pa, the coating chamber is fed with Ar gas, and the Ar gas flow rate is controlled at 10sccm-30sccm, so that the pressure of the coating chamber and the sample chamber is 2Pa;

[0029] The Si substrate was first ultrasonically cleaned in absolute ethanol f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com