Engineering machinery cover and engineering machinery

A technology for engineering machinery and fuselage, which is applied in the field of engineering machinery covers, can solve problems such as unfavorable fuselage protection, damage to hydraulic piping and electrical wiring, etc., to prevent foreign objects such as steel bars or wood, improve opening efficiency, and improve bending rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

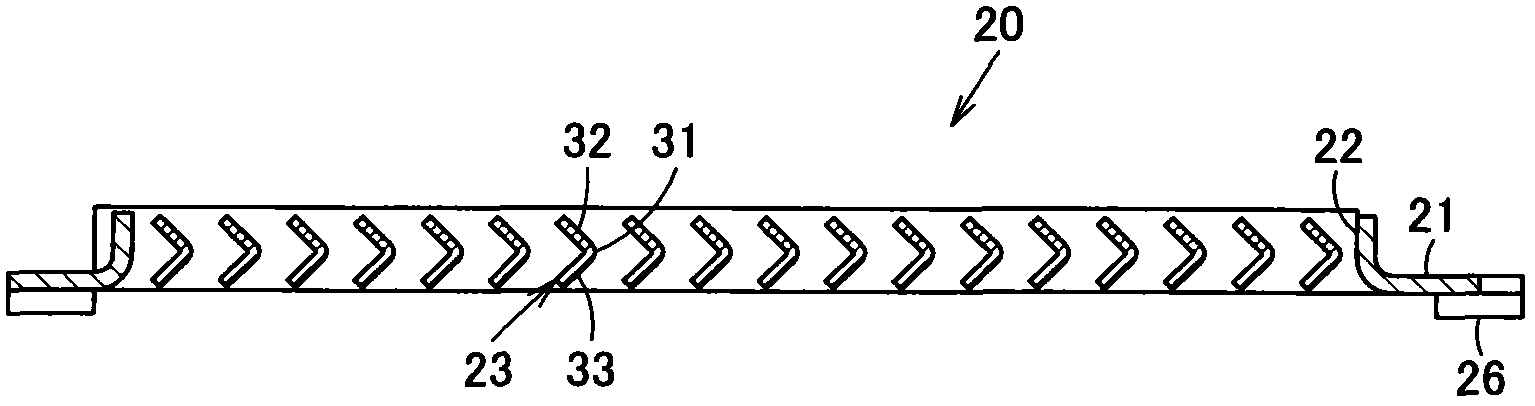

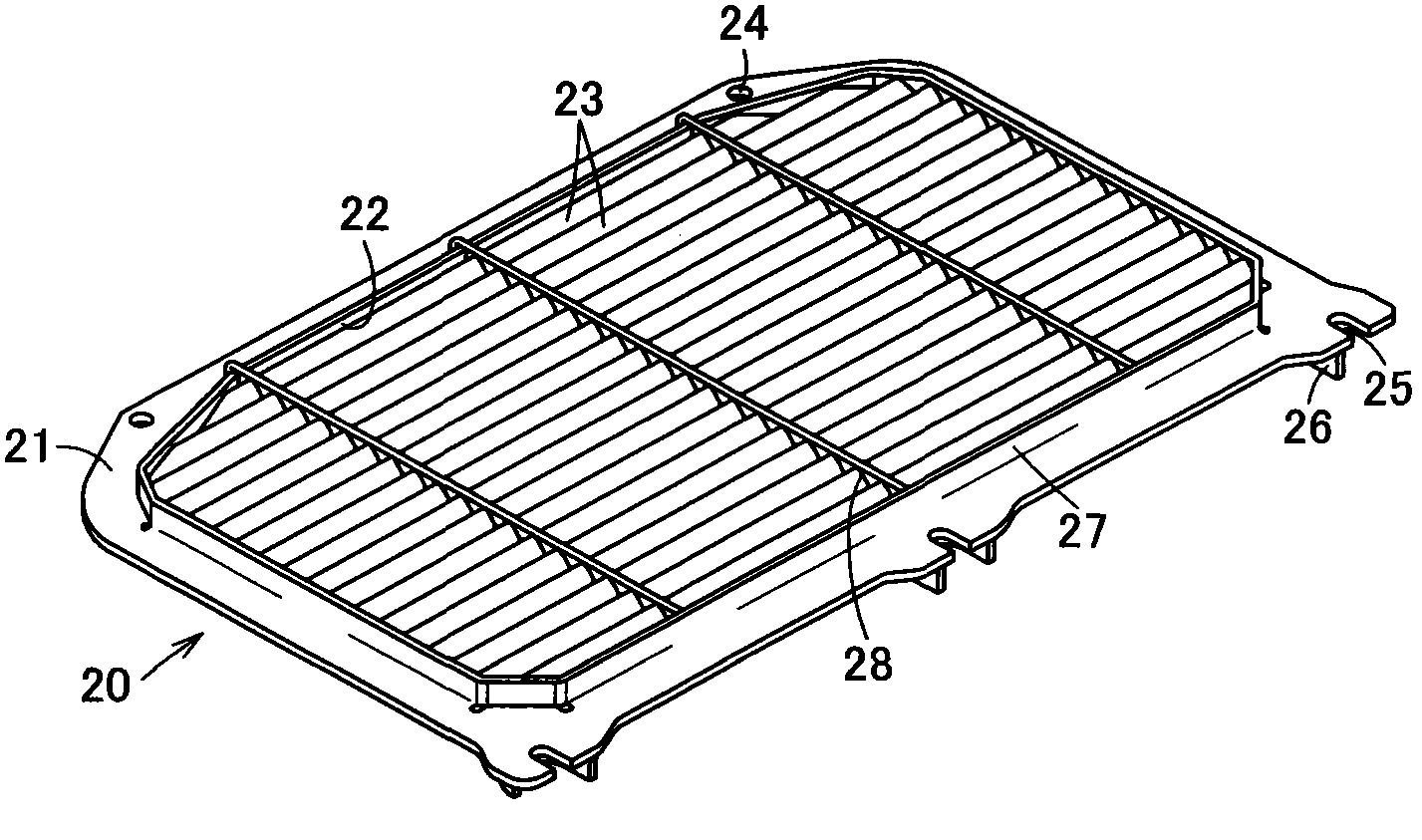

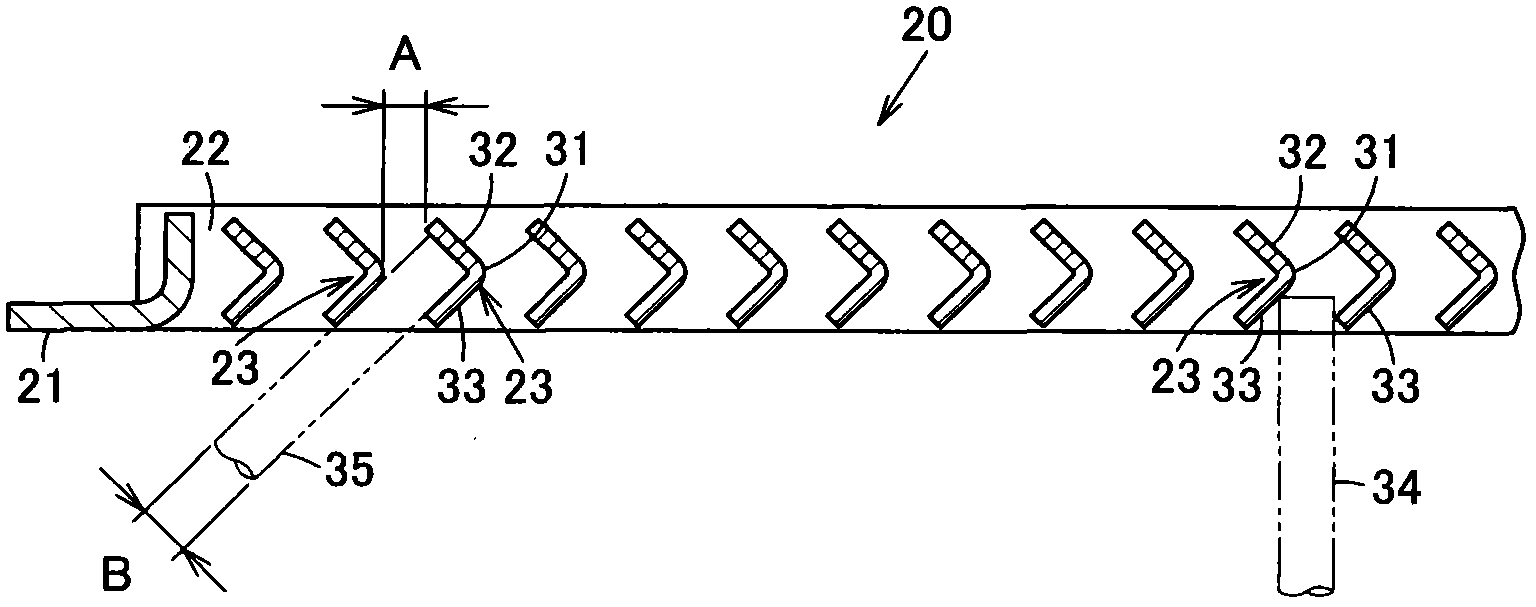

[0042] Below, based on Figure 1 to Figure 4 An embodiment is shown in detail of the invention.

[0043] Figure 4 A hydraulic excavator 11 as a construction machine is shown, which has: a lower traveling body 12; an upper rotating body 13 as a fuselage which is rotatably provided on the lower traveling body 12 and has an opening at the bottom; Working device 14 on body 13. The working device 14 is composed of a boom 15 operated by a hydraulic cylinder, an arm 16 , and attachments 17 such as fork grippers.

[0044] On the upper rotating body 13, there are: a cab 18, a fuel tank (not shown), a working oil tank (not shown), a machine room 19, etc., and an engine (not shown) is housed in the machine room 19 and the engine (not shown) through the engine room 19 is housed. A hydraulic pump (not shown) driven by the engine, etc.

[0045] A plurality of openings (not shown) for maintenance are provided on the bottom of the upper rotating body 13 , and bottom covers for closing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com