Volume variable rotation compressor

A rotary compressor and variable capacity technology, which is applied in the field of compressors, can solve the problems of air leakage and air leakage at the sliding plate, and achieve the effects of avoiding air leakage, low production cost, and good leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

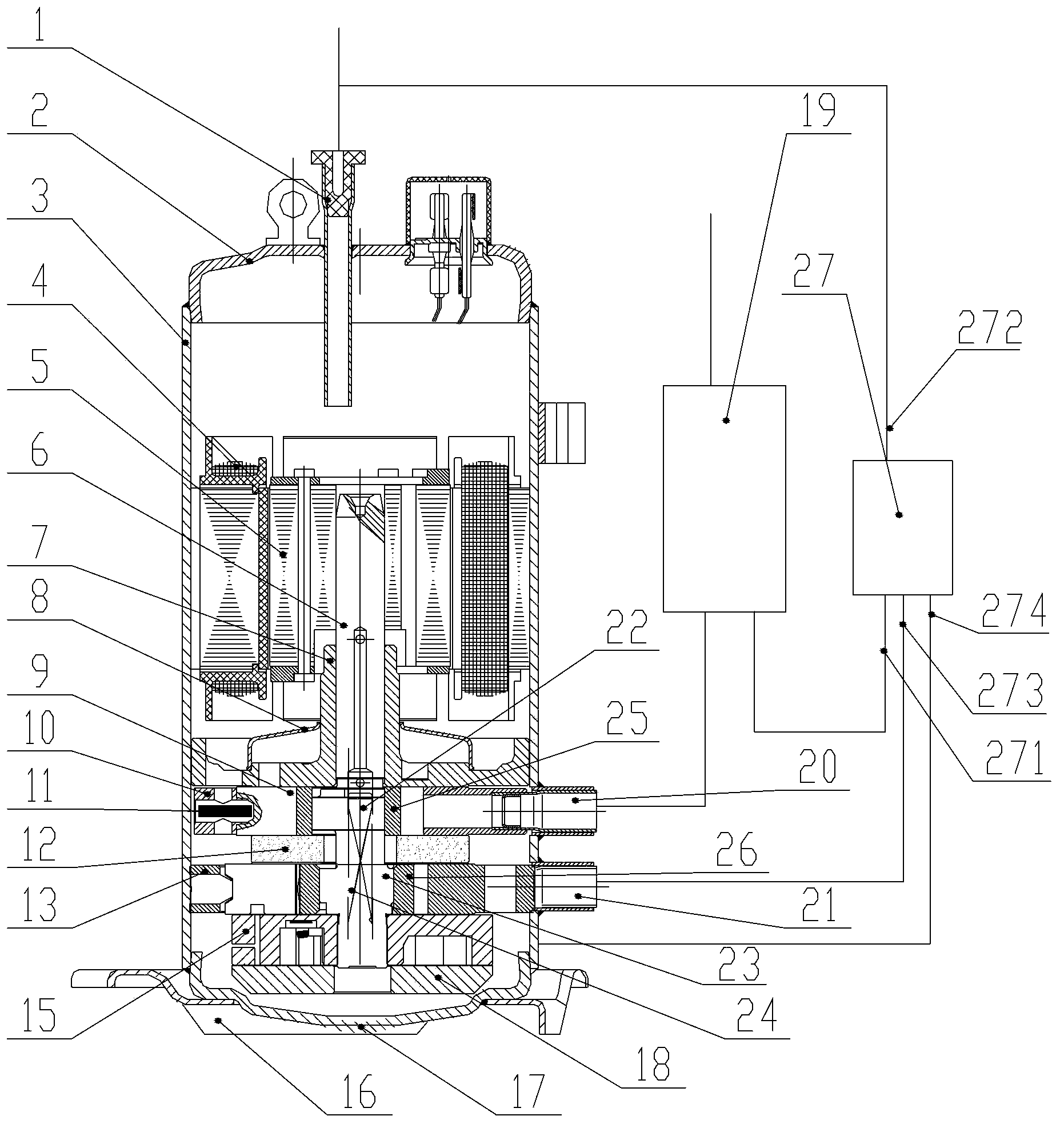

Embodiment 1

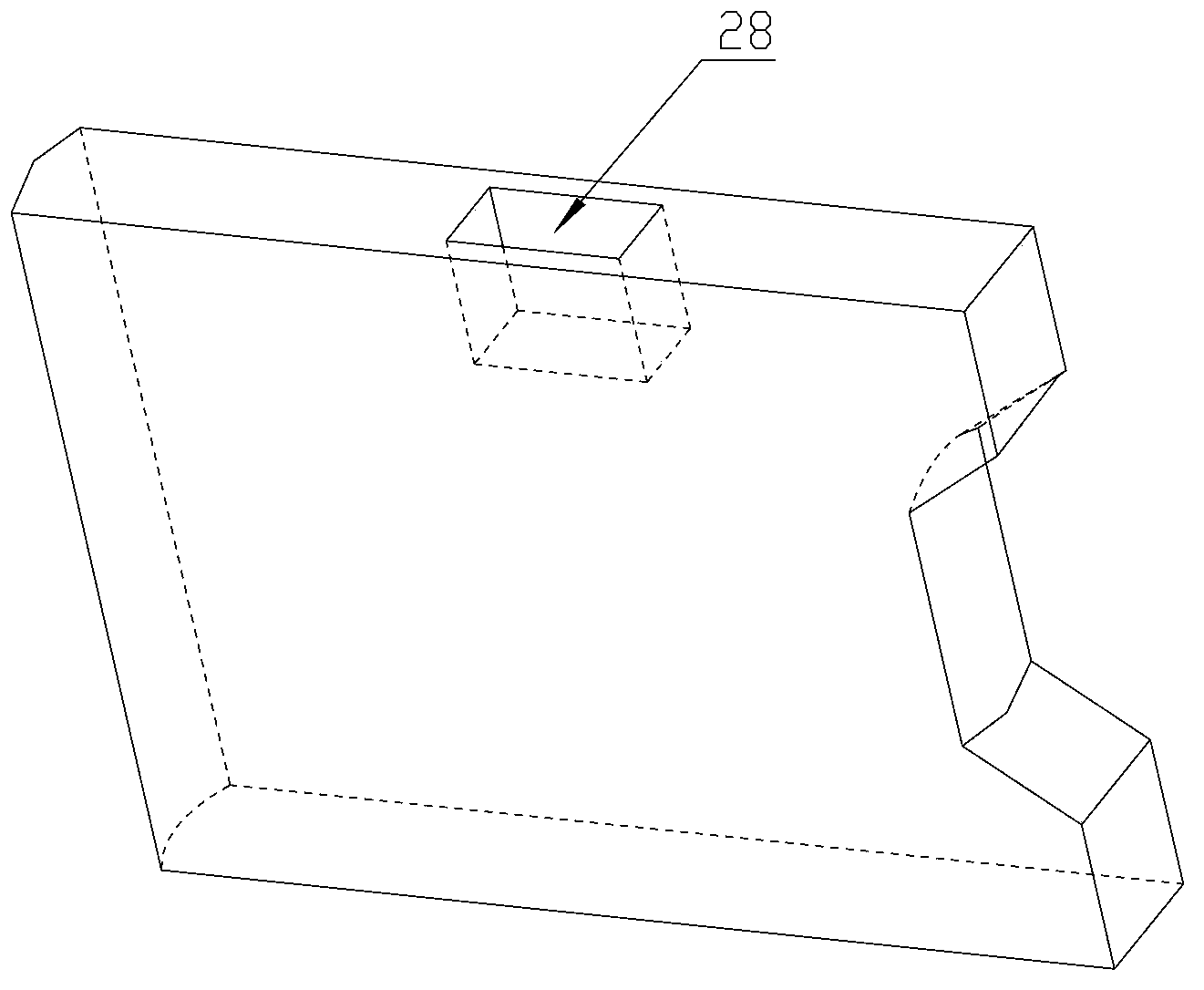

[0048] Such as Figure 1 to Figure 5 As shown, a groove 28 is provided on the end face of the sliding slide 14, and the setting of the groove 28 is equivalent to opening a blind hole in the sliding slide 14. The shape of the groove 28 can be square or circular, preferably square. The end face of the groove 28 is in contact with the sealing end face of the lower flange 15. The lower flange 15 is provided with a lower flange channel 29 for communicating with the groove 28. The diameter of the lower flange channel 29 is d, and the lower flange channel 29 can be It is set as a through hole for communicating with the second outlet of the gas switching device 27; but for the convenience of taking over the pipe, the lower end of the lower flange passage 29 is not opened and becomes a blind hole, and a lower method is set on the side wall of the lower flange passage 29 The blue bypass hole 30, the lower flange bypass hole 30 communicates with the lower flange channel 29, and is used t...

Embodiment 2

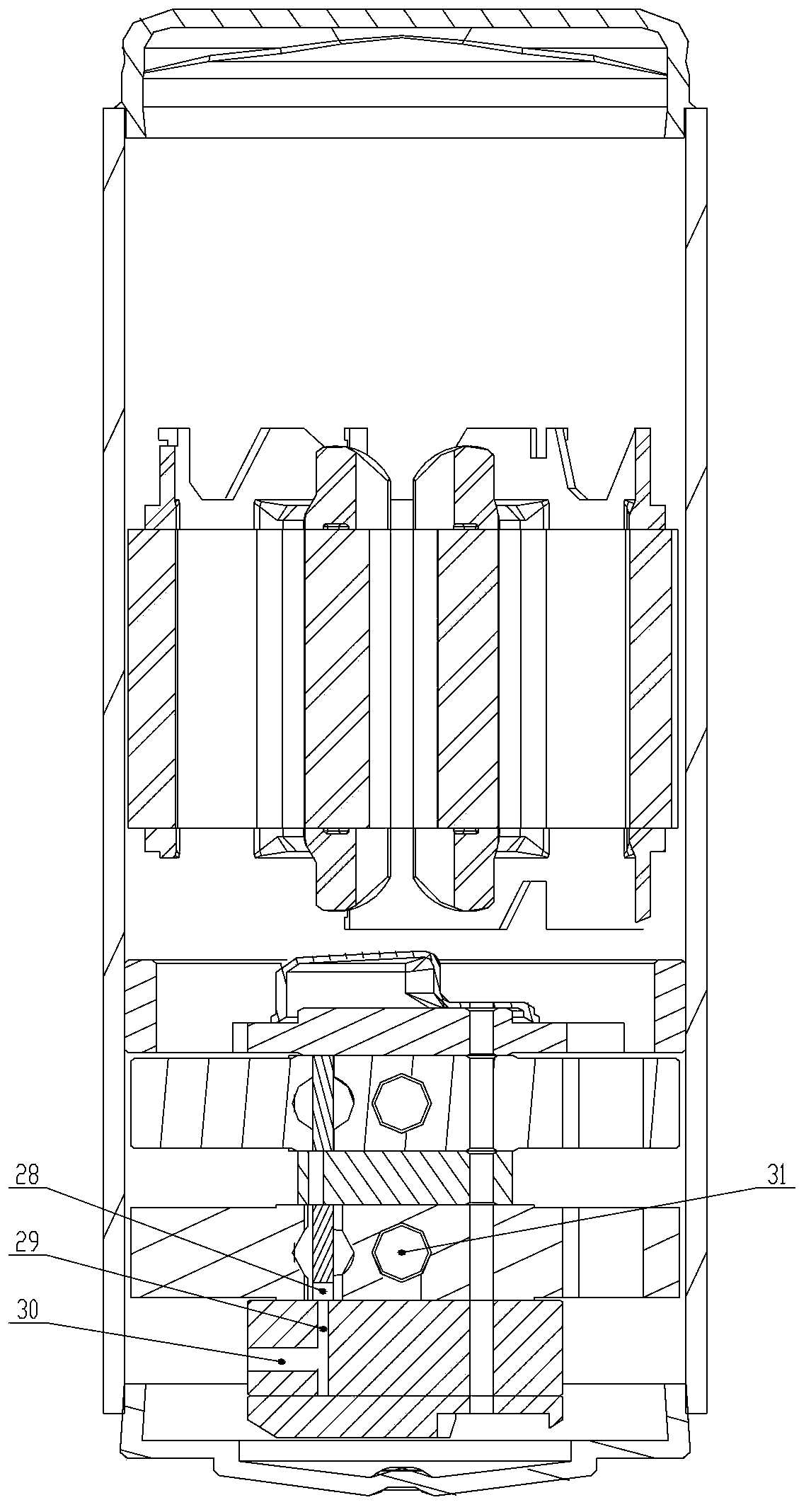

[0058] refer to Figure 6 to Figure 10 , as another embodiment, the difference from Example 1 is that the groove 28 is arranged on the lower flange 15, and is located on an end surface where the lower flange 15 cooperates with the lower cylinder 13, preferably the centerline of the groove 28 is in line with the The center line of the lower slide 14 faces each other, and the lower flange channel 29 is located in the middle of the groove 28 and communicates with the groove 28. One side of the lower flange channel 29 has a lower flange bypass hole 30 for connecting with the gas. The second outlet of the switching device 27 is communicated.

[0059] In order to ensure sealing, the distance between the inner wall of the groove 28 and the outer wall of the sliding slide 14 is greater than or equal to 0.5-1.2mm, and the diameter d of the lower flange channel 29 is less than or equal to the width A of the groove 28 .

[0060] When the center line of the groove 28 coincides with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com