Novel tool for reducing gas residual rate of SF6 steel cylinder

A technology of cylinder gas and residual rate, applied in the field of tools, can solve problems such as low work efficiency, potential safety hazards, uneven heating area, etc., and achieve the effect of low cost, small capital investment, strong practical application value and promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

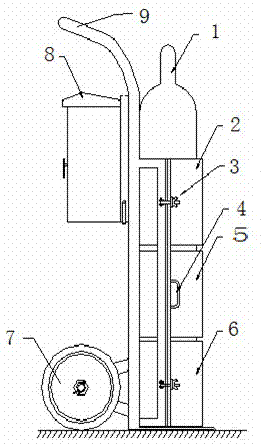

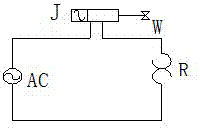

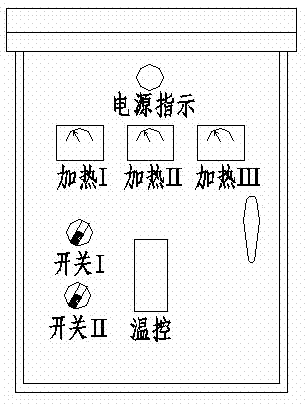

[0011] From Figure 1 to Figure 3 It can be seen that the present invention includes a vertical gas cylinder 1 heating trolley 9, an electric control cabinet 8 mounted on the heating trolley 9, and three sets of heaters, upper, middle and lower; The outer surface is equipped with an insulation layer; the temperature control probe W is installed in the upper heating plate, and the digital temperature controller is installed in the electric control cabinet 8. The control temperature setting range is 10-35℃; on the right side of the upper heating plate A protective switch for safety protection is installed on the surface.

[0012] The electric control cabinet includes fuses, power indicator lights, leakage circuit breakers, ammeters, etc. There are three 0-10A AC ammeters on the panel, which indicate the current value of each phase of the three-phase electricity. The normal working ammeter indicates the same, if there is any indication of the ammeter , Find out whether the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com