Cooling device manufacturing method, cooling device and lighting device

A lighting device and heat dissipation device technology, which is applied in the direction of lighting devices, cooling/heating devices of lighting devices, lighting and heating equipment, etc., can solve the problems of fragile ceramic materials, damage to heat sinks, and reduce the heat dissipation performance of heat sinks, etc., to achieve Long life and high light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

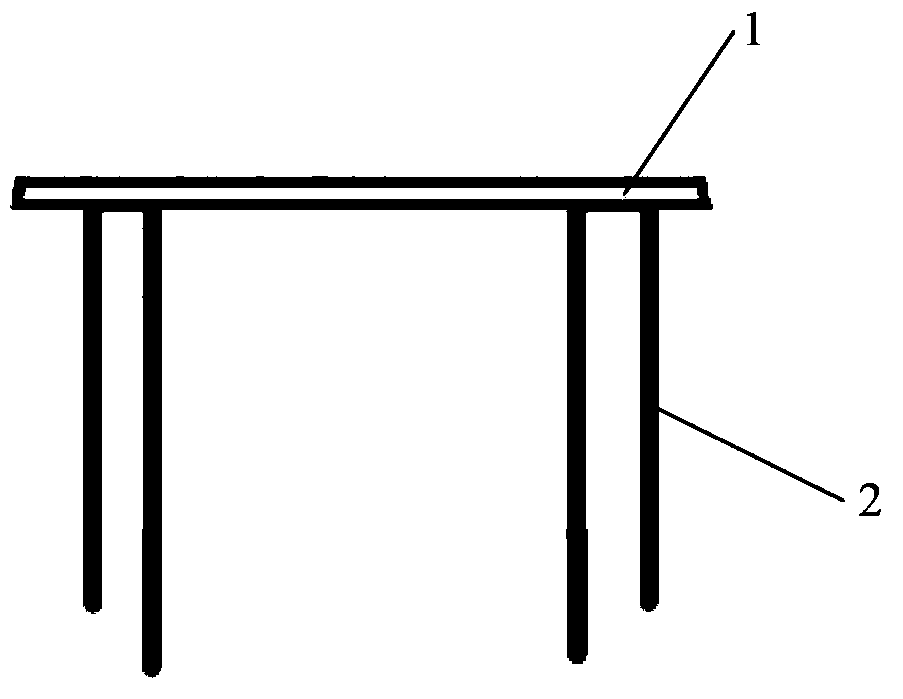

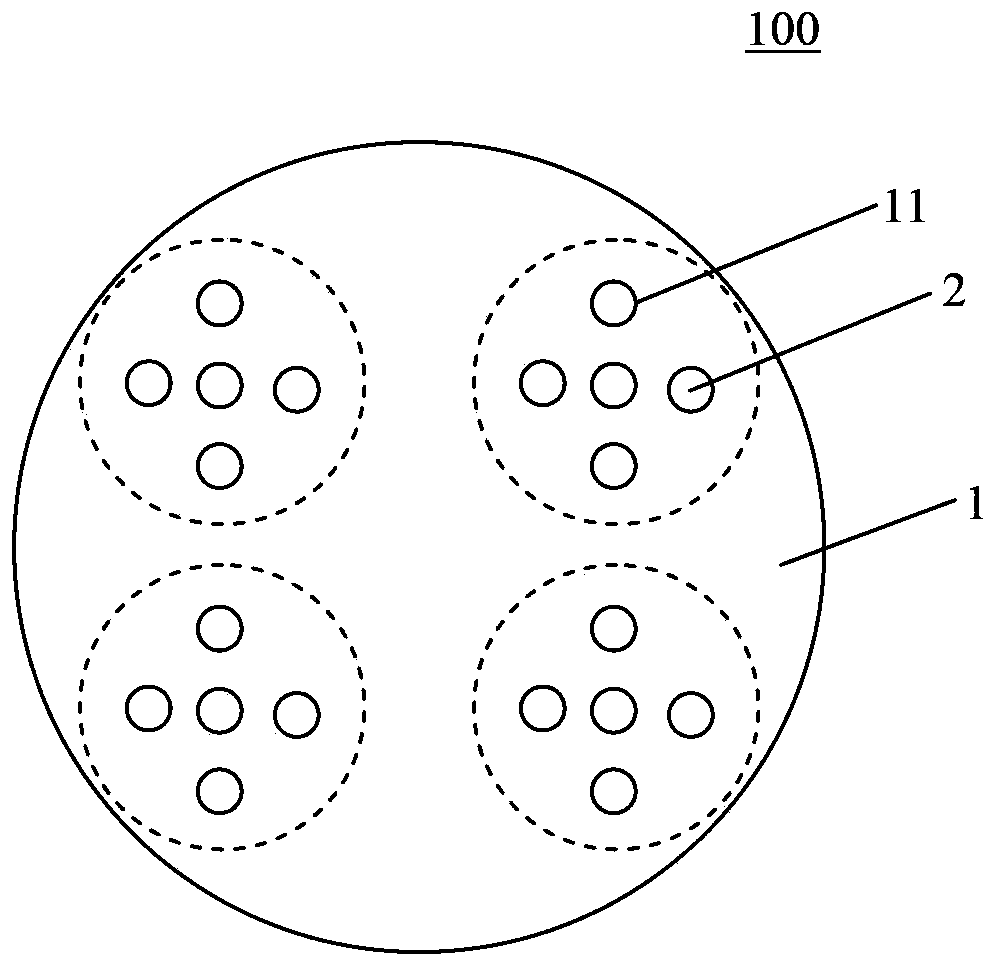

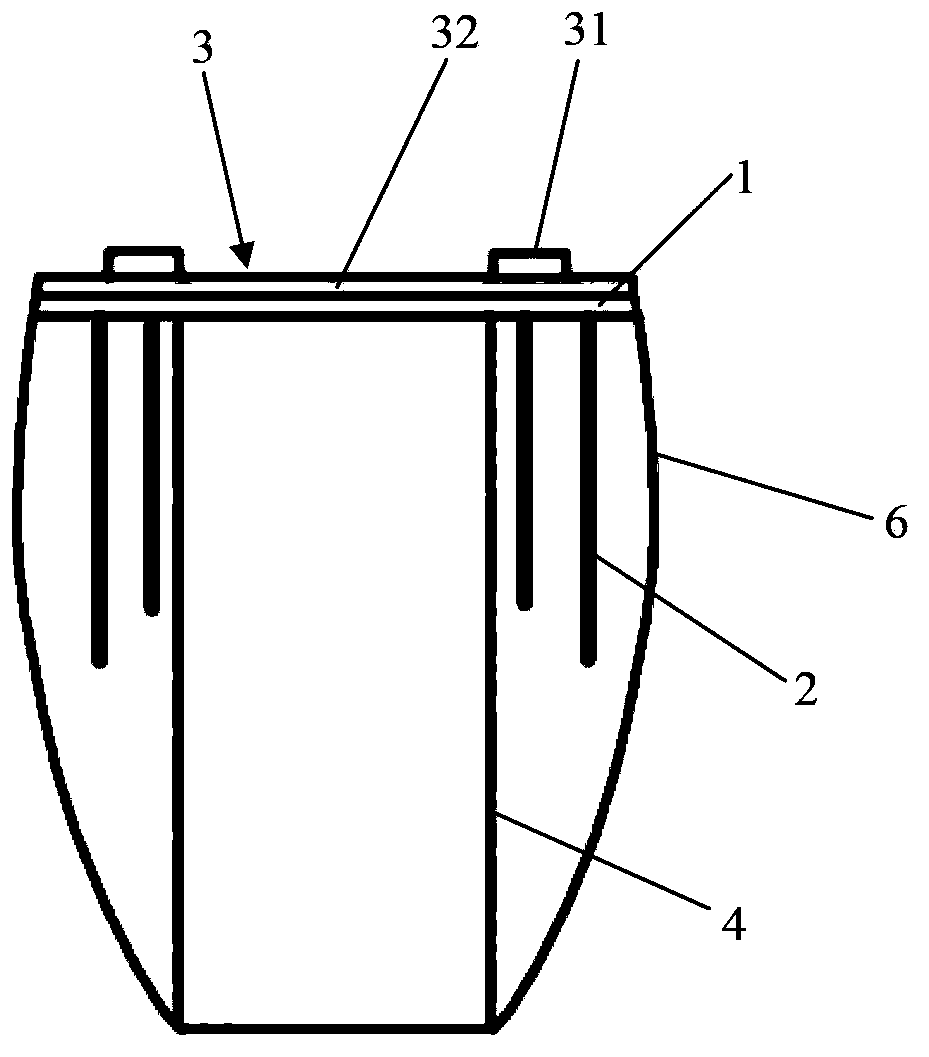

[0025] figure 1 A schematic diagram of a heat dissipation device 100 according to the present invention is shown. It can be seen from the figure that the heat dissipation device 100 according to the present invention includes a base 1 and a plurality of heat sinks 2 arranged on the base 1 . In the method according to the invention, firstly in step a) a base body 1 made of metal by a forging process is provided, then in step b) at least one cooling element 2 is provided which is made of metal by a casting process or by forging process, and finally fix the heat sink 2 to the base 1 in step c. Since the base body 1 is made by a forging process, the base body 1 is usually in the shape of a plate, and the plate-shaped base body 1 has a very simple outline, which is very easy to be processed by a forging process. At the same time, the plate-shaped base 1 can be more closely in thermal contact with the circuit board as the heat source, thereby maximally increasing the contact area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com