Bottom surface appearance inspector

A visual inspection, bottom surface technology, applied in the direction of instruments, optical testing flaws/defects, identification devices, etc., can solve the problems of difficulty in implementation, inaccurate marking, inconvenient inspection marking, etc., to achieve simple structure, convenient maintenance, efficient and rapid inspection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

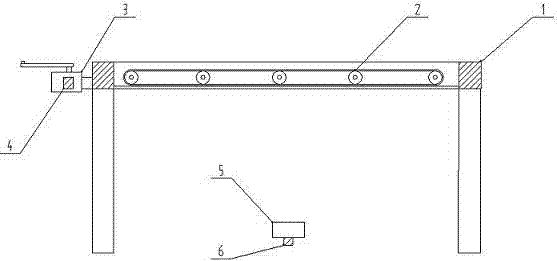

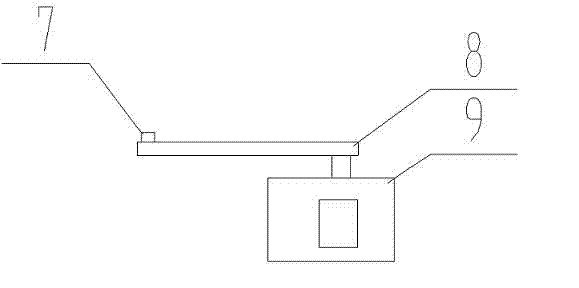

[0014] Such as figure 1 , 2 As shown, a part of the industrial automation assembly line of a bottom surface appearance inspector disclosed by the present invention is used for final appearance inspection of the finished product, which includes an inspection frame 1, a transmission mechanism 2, a guide rail 3, and a marking mechanism 4. A photographing mechanism 5, a support seat 6, and the transmission mechanism 2 are fixed on both sides of the test frame 1 for driving the product placed above to move, and the guide rail 3 is fixed on one end of the test frame 1, and is connected to the test frame 1. The transmission mechanism is arranged vertically, the marking mechanism 4 is sleeved on the guide rail 3, and slides along the guide rail 3, and the shooting mechanism 5 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com