Ultrasonic monitoring sensor for corrosion of steel bar in concrete and application method of sensor

A technology for ultrasonic monitoring and steel corrosion, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, which can solve the problems of environmental noise interference, low steel corrosion accuracy, and inaccurate detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

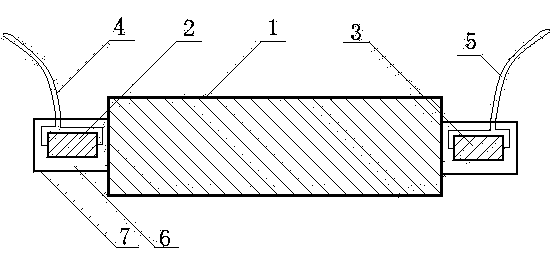

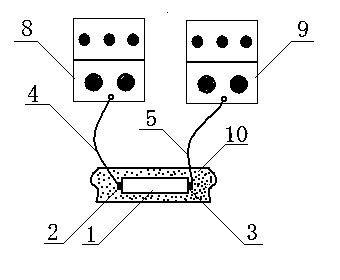

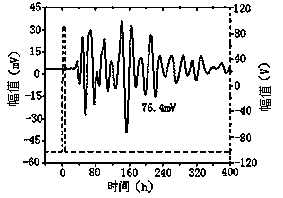

[0010] Referring to the accompanying drawings, the ultrasonic monitoring sensor for steel bar corrosion in the concrete is provided with a steel bar 1, one end of the steel bar 1 is provided with a piezoceramic column 2 for transmitting, and the other end of the steel bar 1 is provided with a piezoceramic column for receiving 3. It is used to receive ultrasonic waves, and the axial direction of the piezoelectric ceramic column 2 and the piezoelectric ceramic column 3 is consistent with the axial direction of the steel bar. The piezoelectric ceramic column 2 for transmitting and the piezoelectric ceramic column 3 for receiving are respectively equipped with The shielding lead wire 4 for transmitting and the shielding lead wire 5 for receiving, the outer surfaces of said piezoelectric ceramic column 2 for transmitting and the piezoelectric ceramic column 3 for receiving are respectively provided with a resin insulating layer 6, and the resin insulating layer 6 is provided with a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com