Touch panel and touch display panel

A touch panel and display module technology, which is applied in the direction of instruments, electrical digital data processing, and input/output process of data processing, etc. It can solve problems such as the reduction of manufacturing engineering yield and the damage of touch panel components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0069] A first embodiment of the present invention provides a touch panel, which includes a substrate, a first conductive layer, an insulating layer, and a second conductive layer.

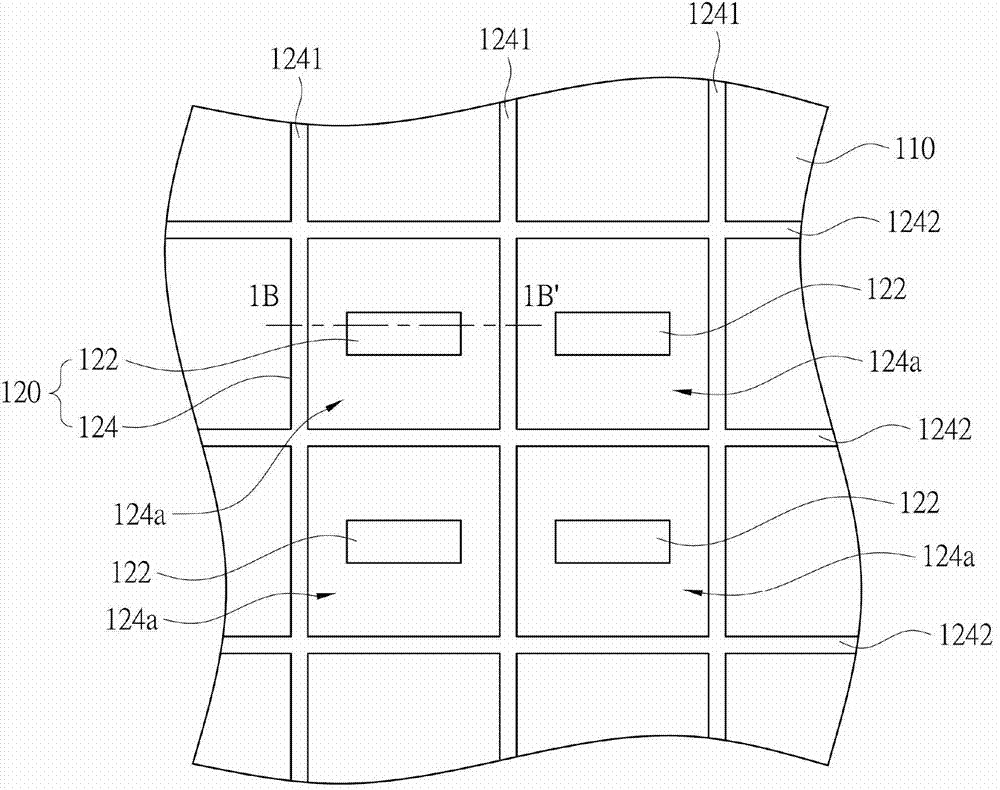

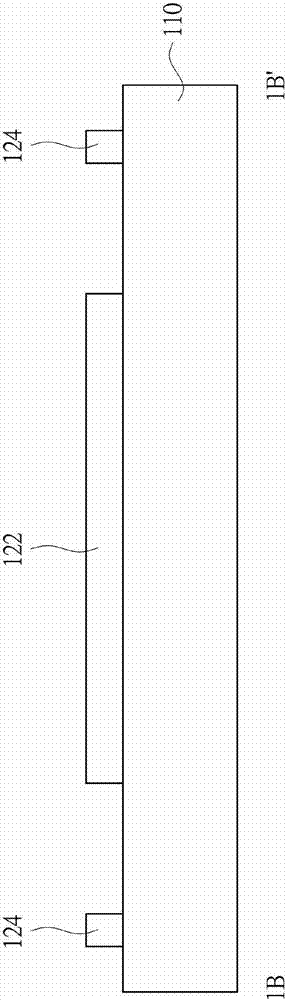

[0070] Figure 1A It is a schematic top view showing the first conductive layer 120 of this embodiment. Figure 1B to show along Figure 1A The schematic cross-sectional view of the line segment 1B-1B'. The first conductive layer 120 is disposed on the substrate 110 . The substrate 110 may be a glass substrate, a quartz substrate or a plastic substrate. The first conductive layer 120 can be made of transparent conductive material or metal. The transparent conductive material is, for example, indium tin oxide (ITO), indium zinc oxide (IZO), zinc oxide (ZnOx), indium gallium zinc oxide (IGZO), gallium zinc oxide (GZO), or a combination thereof. Metals such as molybdenum (Mo), chromium (Cr), neodymium (Nd), titanium (Ti), copper (Cu), silver (Ag), gold (Au), zinc (Zn), indium (In), gallium ( Ga),...

no. 2 approach

[0088] A second embodiment of the present invention provides a touch panel, which includes a substrate, a first conductive layer, an insulating layer, and a second conductive layer.

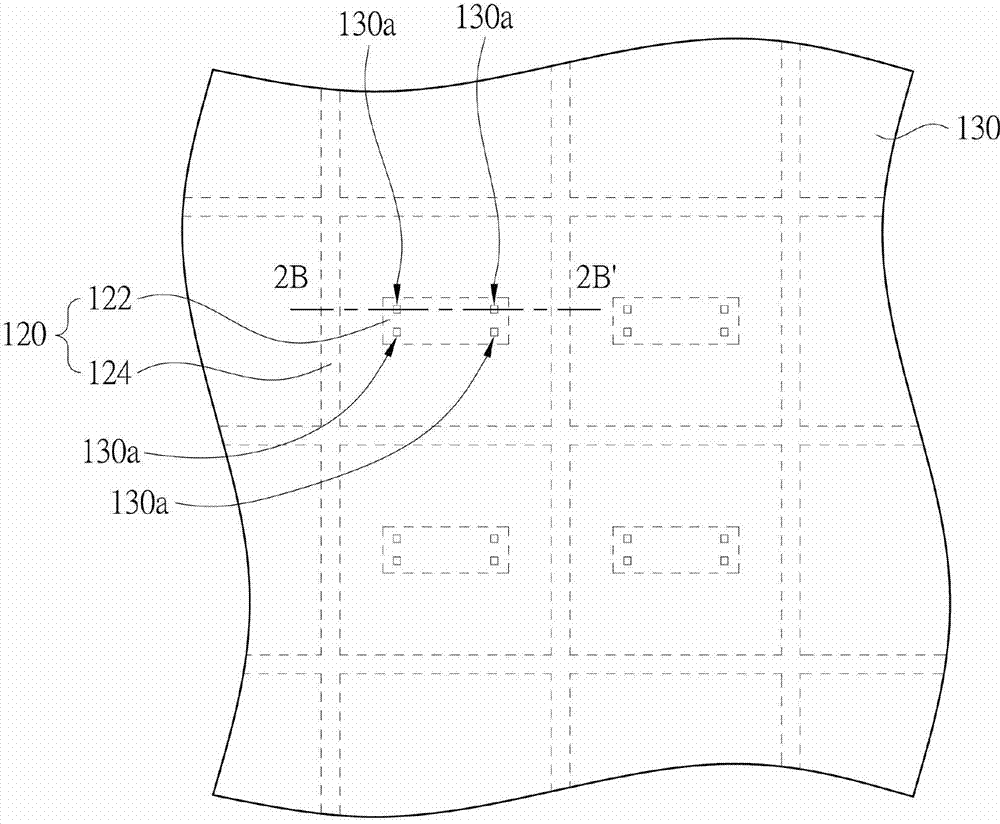

[0089] Figure 9A It is a schematic top view showing the first conductive layer 220 of this embodiment. Figure 9B to show along Figure 9A The schematic cross-sectional view of the line segment 9B-9B'. The first conductive layer 220 is disposed on the substrate 210 . The first conductive layer 220 includes a first sensing series 222 and at least two sensing pads 224 . The first sensing series 222 includes at least one bridge line 2222 and a plurality of sensing pads 2224 . The bridge wire 2222 connects two adjacent sensing pads 2224 in series to form a first sensing series 222 . The two sensing pads 224 are respectively located on opposite sides of the first sensing series 222 . Overall, the first conductive layer 220 may include a plurality of first sensing series 222 and a plurality of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com