Dry type voltage transformer for switchgear

A technology of voltage transformers and switchgear, applied in the direction of inductors, transformers, transformer/inductor coils/windings/connections, etc., can solve the problem of not meeting the requirements for the use of miniaturized switchgear, low insulation protection voltage level, and affecting the normal operation of the power grid Operation and other problems, to improve the electric field distribution, improve the insulation strength, reduce the effect of partial discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

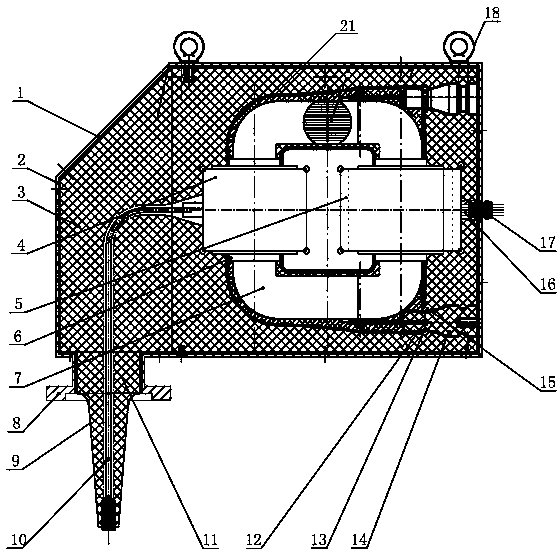

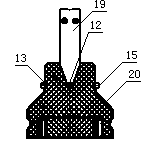

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] Such as figure 1 As shown, the iron core 7 of the dry-type voltage transformer for 66kV switchgear is rectangular, the material is 27ZH105, and the overvoltage factor of the iron core is 2.5. In order to increase the magnetic coupling effect, the number of turns and The balance winding 6 with identical geometric dimensions is used to balance the magnetomotive force of the two legs of the iron core and increase the magnetic coupling effect. The high-voltage primary winding 4 adopts a cascade connection, and two stages with the same number of turns and geometric dimensions are set, respectively wound on the two core columns of the iron core, and are located outside the balanced winding. The series connection of the high-voltage primary winding is connected to the iron The core is used for equal voltage connection, and the voltage transformer core only bears 1∕2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com