Method for improving CIGS mechanical efficiency for scribing in special vacuum adsorbing positioning mode

A vacuum adsorption, vacuum adsorption platform technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve problems such as positioning offset, easy to damage the film surface, and the clip cannot fully grasp the glass.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

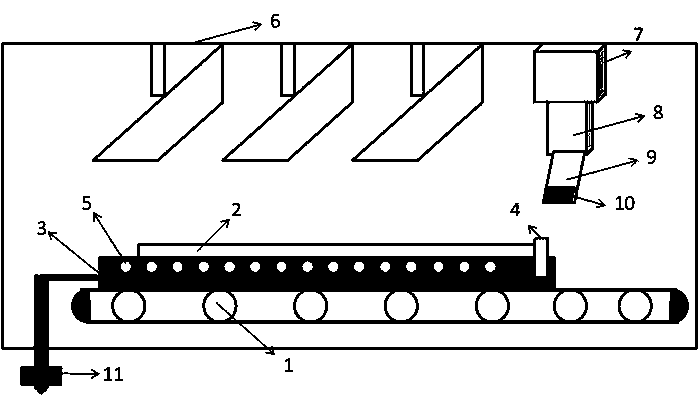

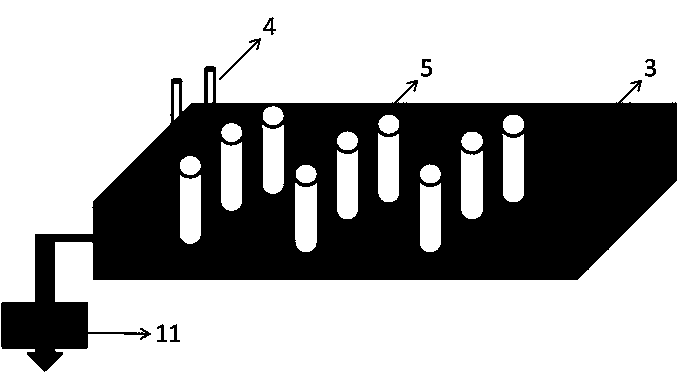

[0008] Hereby the present invention is cooperated with accompanying drawing, detailed description is as follows: figure 1 It is a schematic diagram of the mechanical scribing machine for improving the efficiency of CIGS mechanical scribing by the special vacuum adsorption positioning of the present invention. It can be seen from the figure that CIGS glass 2 is placed on the vacuum platform of the mechanical scribing machine in such a way that the film surface is tangent upward. 3, the vacuum platform can be conveyed by the track bearing 1, and then the glass is pushed onto Pin 4 to fix it. At this time, the vacuum pump 11 is turned on. This vacuum pump is a small pump, which can pump the pressure to several kpa. At this time, the vacuum The vacuum hole 5 on the platform 3 starts to absorb, and the glass will be completely absorbed until it cannot move. Press down, and the mechanical cutter head 9 under the pressing cylinder will make the tungsten steel knife 10 fully conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com