Plant preservative and preparation method thereof

A plant preservative and preservative technology, which is applied in the field of food processing to achieve the effects of good preservation effect, good preservation period and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

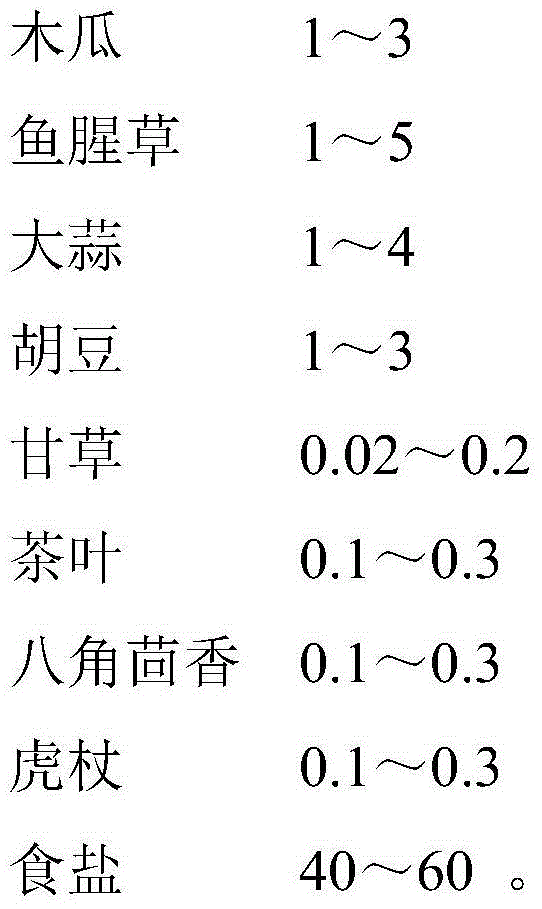

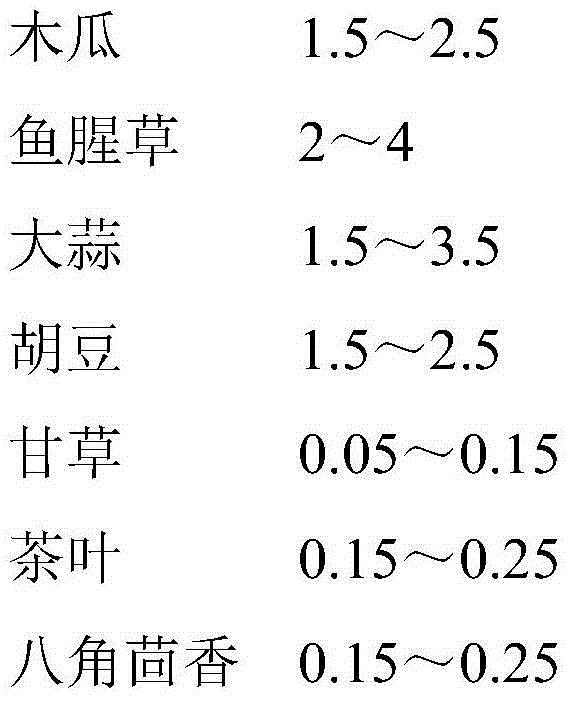

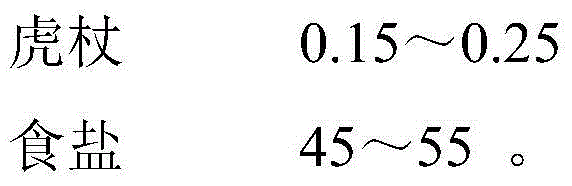

[0028] Plant preservatives, according to the following ratio of raw materials: fresh papaya 1kg, fresh Houttuynia cordata 1kg, garlic 1kg, soybean 1kg, licorice 0.02kg, Kudingcha 0.1kg, star anise 0.1kg, knotweed 0.1kg, salt 40kg.

[0029] According to the ratio of the above raw materials, it is made according to the following method: fresh Houttuynia cordata is extracted from the juice to remove residue, fresh papaya is extracted from the juice to remove residue, garlic is sliced, licorice and Kudingcha are made into powder, whole beans are added, and star anise , Polygonum cuspidatum and table salt are mixed and soaked in water, and then the residue is filtered to obtain a preservative.

[0030] Above-mentioned raw material is put into 300kg fresh capsicum and pickled capsicum kimchi by conventional technology.

Embodiment 2

[0032] Plant preservatives, according to the following ratio of raw materials: fresh papaya 1.5kg, fresh Houttuynia cordata 2kg, garlic 1.5kg, soybean 1.5kg, licorice 0.05kg, Kudingcha 0.15kg, star anise 0.15kg, Polygonum cuspidatum 0.15kg, salt 45kg.

[0033] According to the ratio of the above raw materials, it is made according to the following method: fresh Houttuynia cordata is extracted from the juice to remove residue, fresh papaya is extracted from the juice to remove residue, garlic is sliced, licorice and Kudingcha are made into powder, whole beans are added, and star anise , Polygonum cuspidatum and table salt are mixed and soaked in water, and then the residue is filtered to obtain a preservative.

[0034] Above-mentioned raw material is put into 400kg fresh capsicum and is pickled capsicum pickle by conventional technology.

Embodiment 3

[0036] Plant preservatives, according to the following raw material ratio: fresh papaya 2kg, fresh Houttuynia cordata 3kg, garlic 2.5kg, soybean 2kg, licorice 0.1kg, Kudingcha 0.2kg, star anise 0.2kg, knotweed 0.2kg, salt 50kg.

[0037] According to the ratio of the above raw materials, it is made according to the following method: fresh Houttuynia cordata is extracted from the juice to remove residue, fresh papaya is extracted from the juice to remove residue, garlic is sliced, licorice and Kudingcha are made into powder, whole beans are added, and star anise , Polygonum cuspidatum and table salt are mixed and soaked in water, and then the residue is filtered to obtain a preservative.

[0038] Above-mentioned raw material is put into 500kg fresh capsicum and pickled capsicum kimchi by conventional technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com