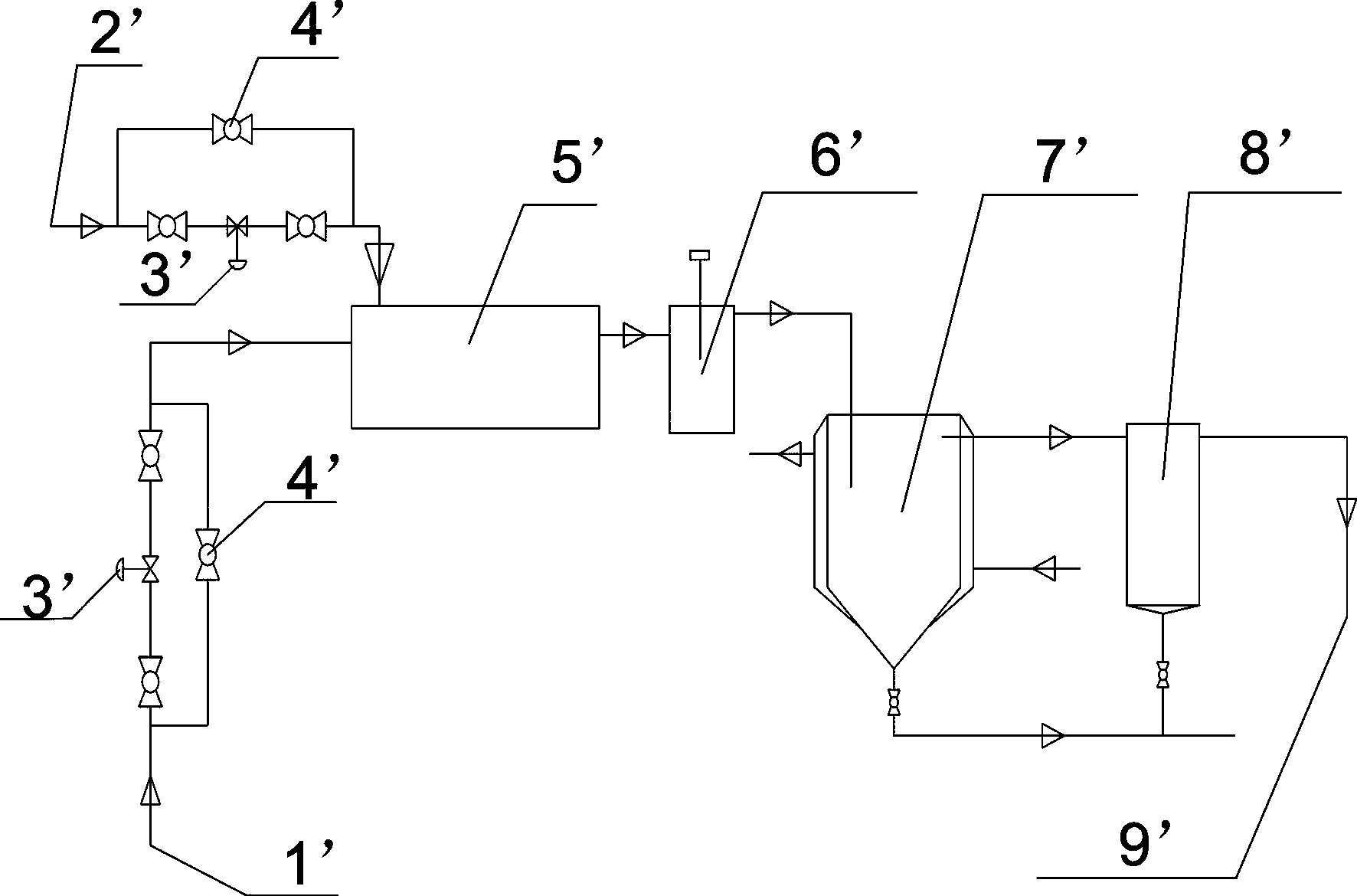

Drying device and method for triethylamine in production process of glyphosate

A technology of production process and drying equipment, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve problems such as long drying time, high consumption of caustic soda, and too fast hydrolysis of dimethyl phosphite, etc. Achieve high porosity and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

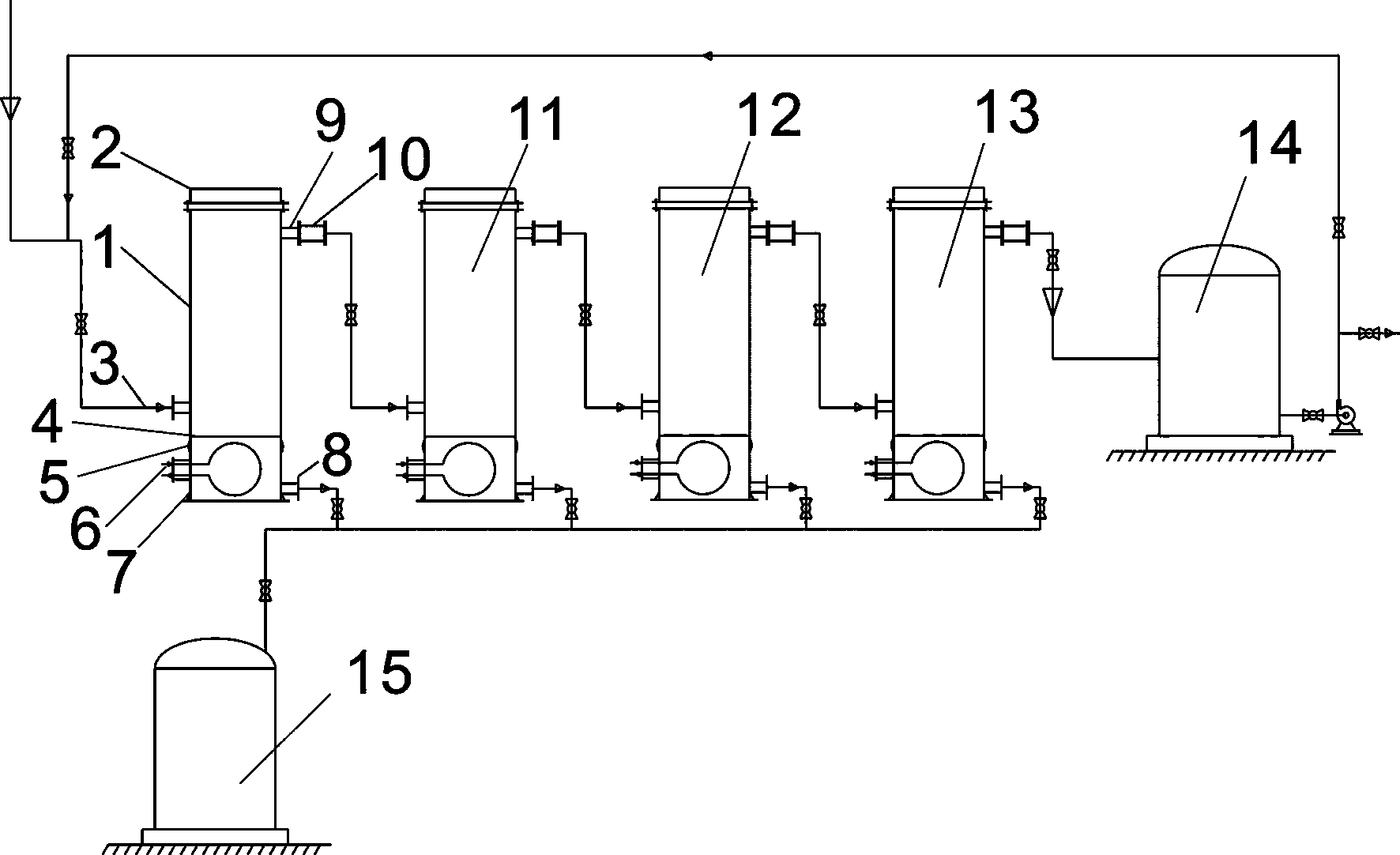

[0016] The triethylamine with a water content of about 1% in the subsequent process of glyphosate production is pumped from the triethylamine primary storage tank to the primary drying tower 1. According to the current glyphosate 100t / day calculation, the input of triethylamine The volume is 80t. When entering the first-level drying tower, the inlet flow rate is kept at 12.6t / h, and then solid alkali is injected into the first-level drying tower 1. The mass ratio of triethylamine aqueous solution and solid alkali is controlled within 1:1.9, and the flow control is put into Within 1480kg / h and keep the height of the solid alkali layer lower than 100mm from the outlet of triethylamine;

[0017] The dried triethylamine is put into the secondary drying tower 11 again, and the inlet flow rate is kept at 12.6t / h, and then the solid alkali is fed into the secondary drying tower 11, and the mass ratio of the triethylamine aqueous solution and the solid alkali is controlled within 1:1.7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com