Fine particle aggregating device under aggregating agent and jet effects

A technology of particle agglomeration and agglomeration agent, applied in the field of flue gas dust removal, it can solve problems such as changing particle surface and increasing effective collision between particles, and achieves the effect of solving bottleneck restrictions, wide operating area and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

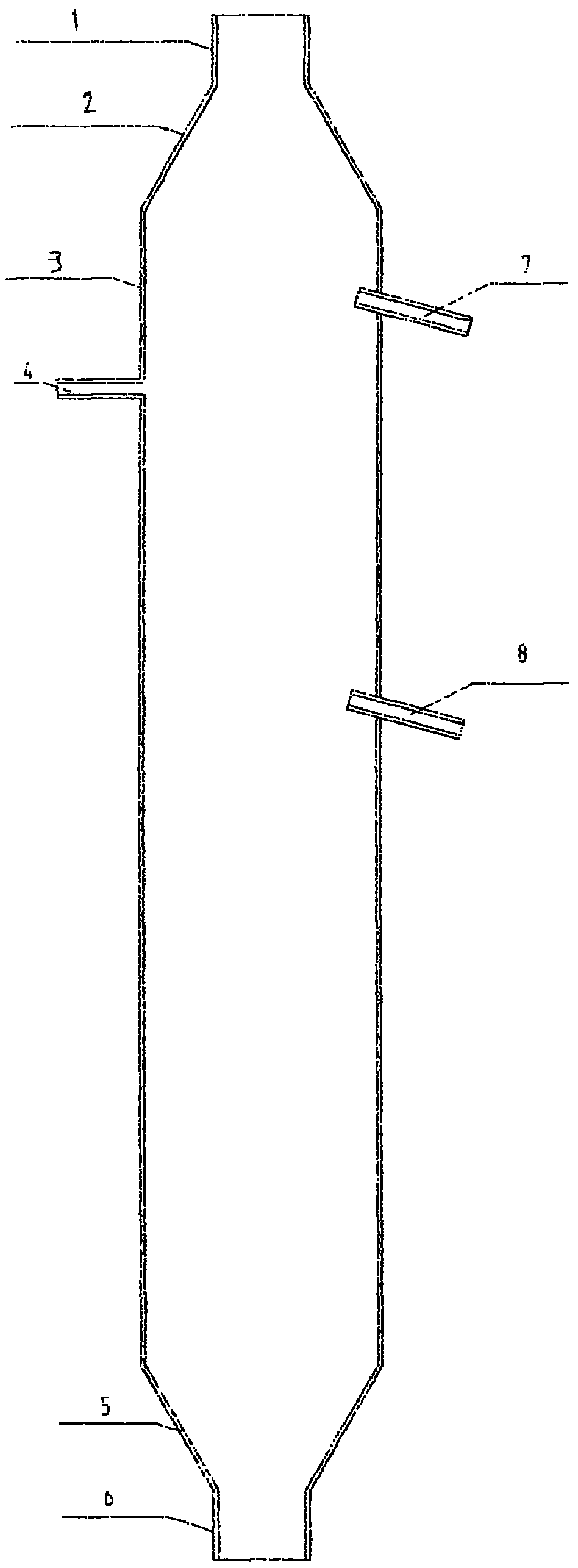

[0011] combined with figure 1 The agglomeration device of the present invention is described. The agglomeration device includes a dusty gas inlet 1, an enlargement section 2, a particle agglomeration chamber 3, a contraction section 5, a narrowing outlet 6, a primary jet tube 7, a secondary jet tube 8 and an agglomerating agent spray port 4 . The particle agglomeration chamber 3 is a three-dimensional vertical equipment with a section of 400×400mm and a height of 2000mm. The dusty gas inlet 1 and the narrowing outlet 5 are circular connection ports with a diameter of 150mm. The enlargement section 2 is a smooth enlargement inlet. In order to achieve the best effect, the included angle of the inlet is 20-30°; the shrinkage section 5 is also a smooth transition structure to reduce the impact of the shrinkage structure on the fragmentation and disturbance of particle aggregates. The primary jet tube 7 is installed on the rear side of the amplification section 3.5d 0 , fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com