Wave-spring processing system and processing method

A wave spring and processing system technology, applied in the field of spring manufacturing, can solve the problems of unreasonable wave spring process arrangement, non-correspondence between wave peaks and wave troughs, and insufficient closeness between layers, so as to save equipment costs and low manufacturing costs , the effect of high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

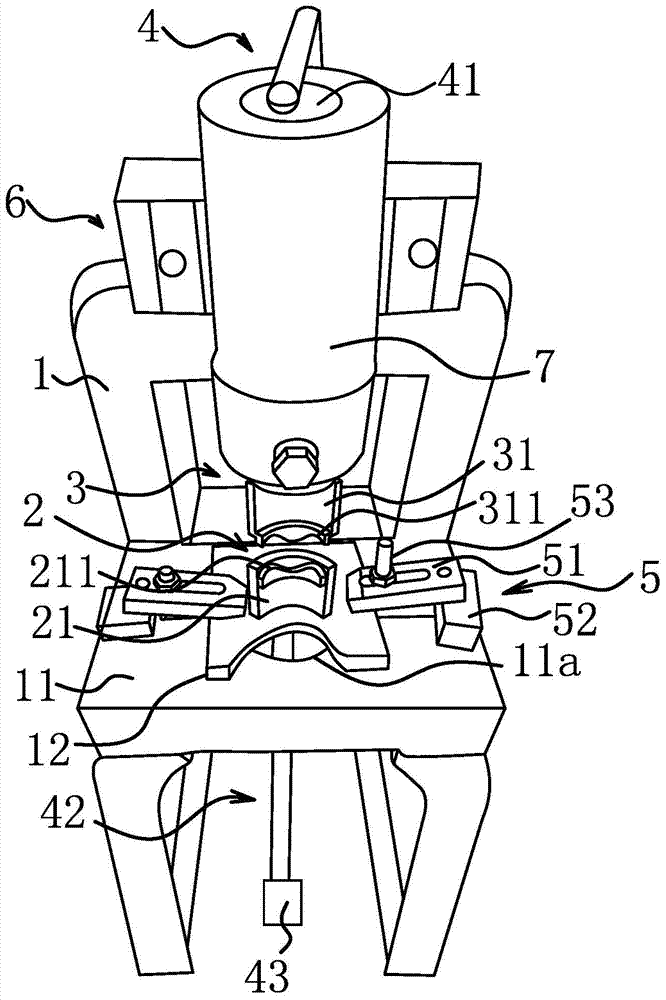

[0025] like figure 1 As shown, the wave spring processing system includes a frame 1, and a static mold 2 and a movable mold 3 opposite to each other are arranged on the frame 1. The static mold 2 is fixed on the frame 1, and the movable mold 3 is connected with a drive The movable mold 3 and the static mold 2 are interlocked or separated from each other by a drive mechanism 4. The static mold 2 is tile-shaped and a static tile block 21 is provided inside the static mold 2. The end of the static tile block 21 has a wavy shape. The static molding surface 211 of the movable mold 3 is tile-shaped and a movable tile block 31 is provided on the inner side of the movable mold 3. There is a wavy dynamic molding surface 311 at the end of the movable tile block 31. The static molding surface 211 and the dynamic molding surface The molding surface 311 is opposite and the static molding surface 211 coincides with the dynamic molding surface 311 when the movable mold 3 is fastened with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com