Energy-saving cooling method

A cooling method and cooling method technology, applied in chemical instruments and methods, sustainable manufacturing/processing, inorganic chemistry, etc., can solve problems such as easy scaling and blockage, easy corrosion and leakage, and difficult inspection and maintenance, and achieve easy operation and maintenance Simple, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

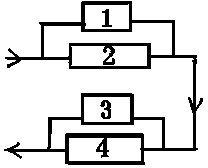

[0017] figure 1 It is a schematic diagram of an embodiment of an energy-saving cooling method of the present invention.

[0018] It can be seen from the figure: a combined device that uses an air-cooled heat exchanger 2 plus a water-cooled heat exchanger 3, and connects a bypass valve 1, 4 in parallel to the two heat exchangers 2, 3; Different, the material can be fully water-cooled, or air-cooled-water-cooled, or fully air-cooled, three different cooling combinations.

[0019] In summer, first use the air-cooled heat exchanger 2 to cool the material, and when the temperature of the material is cooled to 50°C, then connect the cooling water heat exchanger 3 to cool the material to the required temperature.

[0020] In winter, the cooling water heat exchanger 3 is closed, and only the air-cooled heat exchanger 2 is used to exchange heat for the material to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com