Treatment method for dyeing wastewater

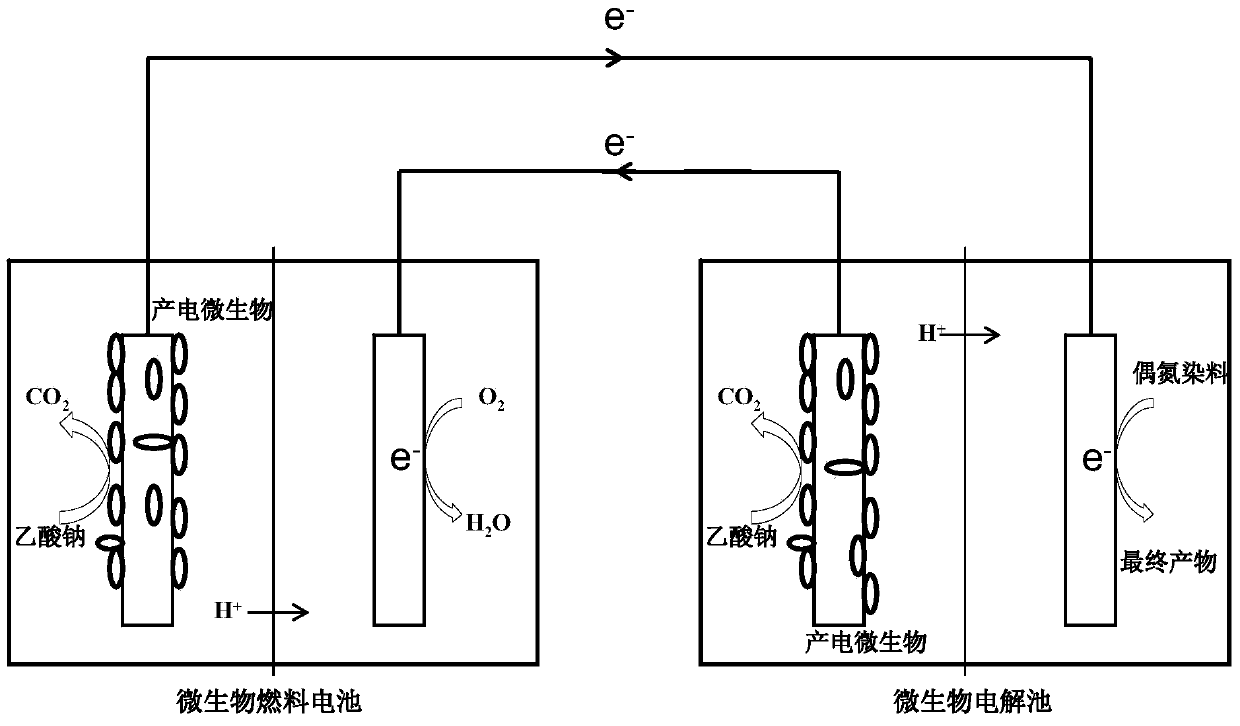

A dye wastewater, fuel cell technology, applied in chemical instruments and methods, textile industry wastewater treatment, biological water/sewage treatment, etc., can solve the problems of wasting energy, low treatment efficiency, small current, etc., to save energy and improve efficiency. , the effect of improving the degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] Example 1: In an uncoupled microbial electrochemical system, when the concentration of the dye wastewater (Acid Orange 7) fed to the cathode is 0.7 mM and the pH is 7, after being degraded by a single MFC, the acid orange 7 (AO7 ) removal efficiency is only 35.0%±2.0%.

example 2

[0028] Example 2: In the novel microbial electrochemical coupling system of this embodiment, when the concentration of the dye wastewater AO7 in the cathode feedwater in the MEC is consistent with the concentration in Example 1, and the same pH is 7, after the coupling system of this embodiment is degraded, The removal efficiency of AO7 was calculated to be 79.0%±1.0%.

[0029] Using methyl orange as the dye wastewater, it can be known through treatment that:

[0030] Example 1: In an uncoupled microbial electrochemical system, when the concentration of the dye wastewater (methyl orange) fed into the cathode is 0.9mM and the pH is 7, after degradation by a single MFC, the methyl orange (MO ) removal efficiency is only 50.0% ± 0.5%.

[0031] Example 2: In the new microbial electrochemical coupling system of the present invention, when the concentration of the dye wastewater MO in the cathode feedwater in the MEC is consistent with the concentration in Example 1, and the same p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com