Method for utilizing low-concentration acetic acid wastewater

A low-concentration acetic acid and waste water technology, applied in chemical instruments and methods, water pollutants, water/sewage multi-stage treatment, etc., can solve the problems of strict operation requirements, high equipment investment cost, large floor area, etc., and achieve treatment Good effect, safe and stable operation, high processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: it comprises the following steps:

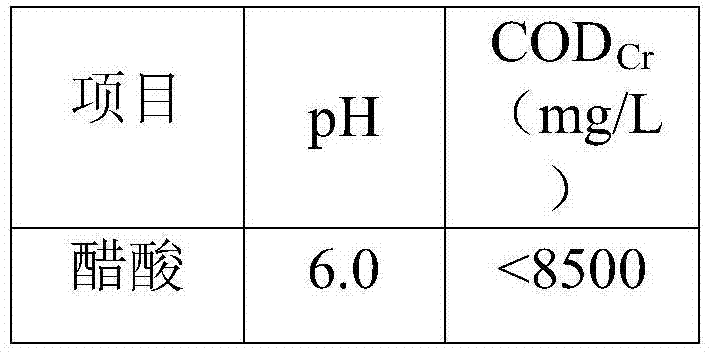

[0020] (1) Filtration treatment: first filter and remove acetic acid wastewater;

[0021] (2) Neutralization treatment: Add potassium hydroxide to the filtered acetic acid wastewater for neutralization reaction, use a mixer to stir the acetic acid wastewater and potassium hydroxide to fully mix, acetic acid and potassium hydroxide react to form potassium acetate, and adjust the concentration of acetic acid wastewater pH to 8;

[0022] (3) Concentration treatment: the acetic acid waste water obtained after neutralization is passed to the cooling water tower to replenish water for the cooling water tower. With the operation of the cooling water tower system, the concentration of potassium acetate in the cooling water of the cooling water tower increases;

[0023] (4) Evaporation and crystallization: After the potassium acetate in the cooling water of the cooling tower reaches 50g / L, the obtained cooling water is evaporate...

Embodiment 2

[0024] Embodiment 2: it comprises the following steps:

[0025] (1) Filtration treatment: first filter and remove acetic acid wastewater;

[0026] (2) Neutralization treatment: Add potassium hydroxide to the filtered acetic acid wastewater for neutralization reaction, use a mixer to stir the acetic acid wastewater and potassium hydroxide to fully mix, acetic acid and potassium hydroxide react to form potassium acetate, and adjust the concentration of acetic acid wastewater pH to 7;

[0027] (3) Concentration treatment: the acetic acid waste water obtained after neutralization is passed to the cooling water tower to replenish water for the cooling water tower. With the operation of the cooling water tower system, the concentration of potassium acetate in the cooling water of the cooling water tower increases;

[0028] (4) Evaporation and crystallization: After the potassium acetate in the cooling water of the cooling tower reaches 2700g / L, the resulting cooling water is evapor...

Embodiment 3

[0029] Embodiment 3: it comprises the following steps:

[0030] (1) Filtration treatment: first filter and remove acetic acid wastewater;

[0031] (2) Neutralization treatment: Add potassium hydroxide to the filtered acetic acid wastewater for neutralization reaction, use a mixer to stir the acetic acid wastewater and potassium hydroxide to fully mix, acetic acid and potassium hydroxide react to form potassium acetate, and adjust the concentration of acetic acid wastewater pH to 9;

[0032] (3) Concentration treatment: the acetic acid waste water obtained after neutralization is passed to the cooling water tower to replenish water for the cooling water tower. With the operation of the cooling water tower system, the concentration of potassium acetate in the cooling water of the cooling water tower increases;

[0033] (4) Evaporation and crystallization: After the potassium acetate in the cooling water of the cooling tower reaches 20g / L, the obtained cooling water is evaporate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com