Weather-proof mildew-resistant antibacterial polycarbonate composition

A mildew-proof and anti-bacterial polycarbonate technology, applied in the field of polymer composite materials, can solve the problems of difficult molding, high impact strength, notch sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific examples, but the examples are only used to illustrate the present invention rather than limit the present invention.

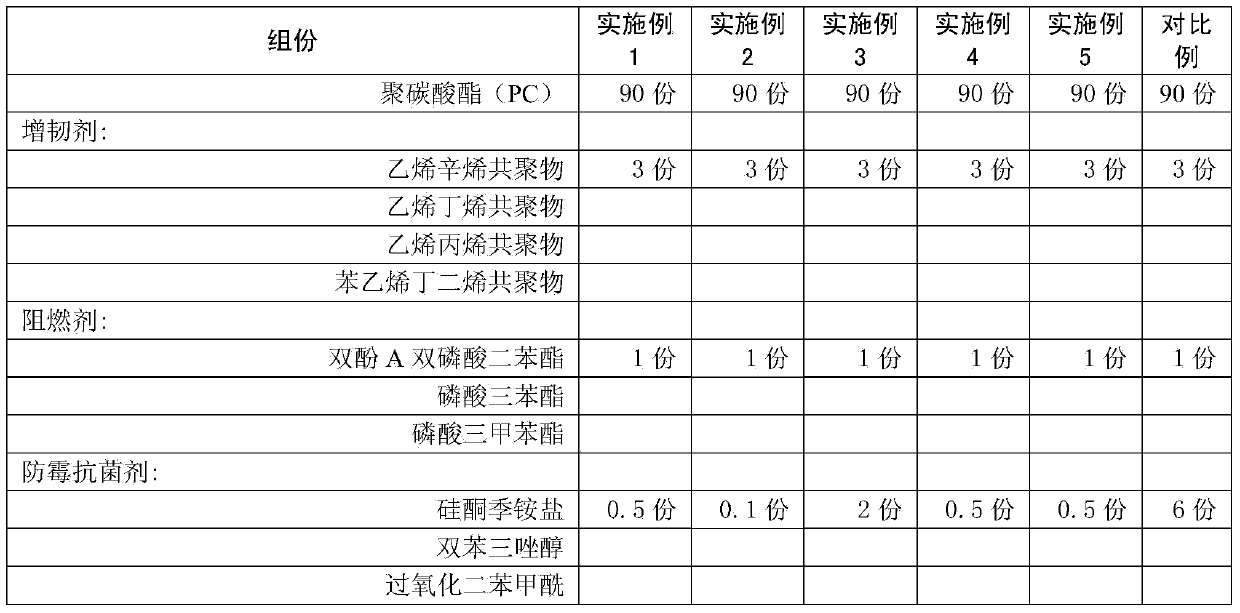

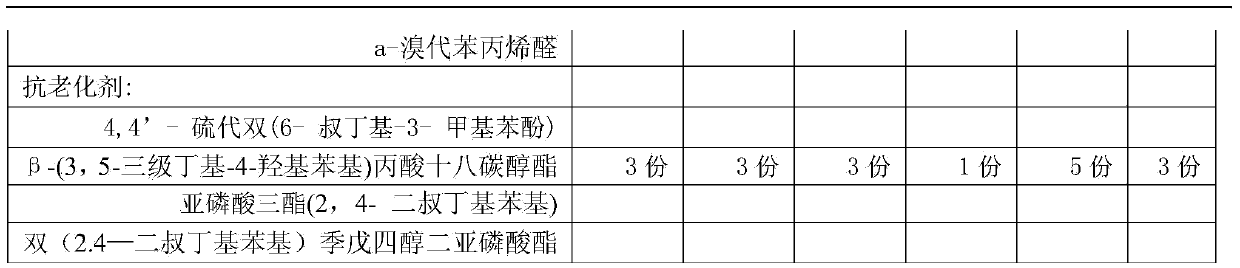

[0012] The composition of a kind of weather-resistant, mildew-proof and antibacterial polycarbonate composition of various embodiments of the present invention and comparative examples is as shown in Table 1 in parts by weight:

[0013] Table I:

[0014]

[0015] manual

[0016]

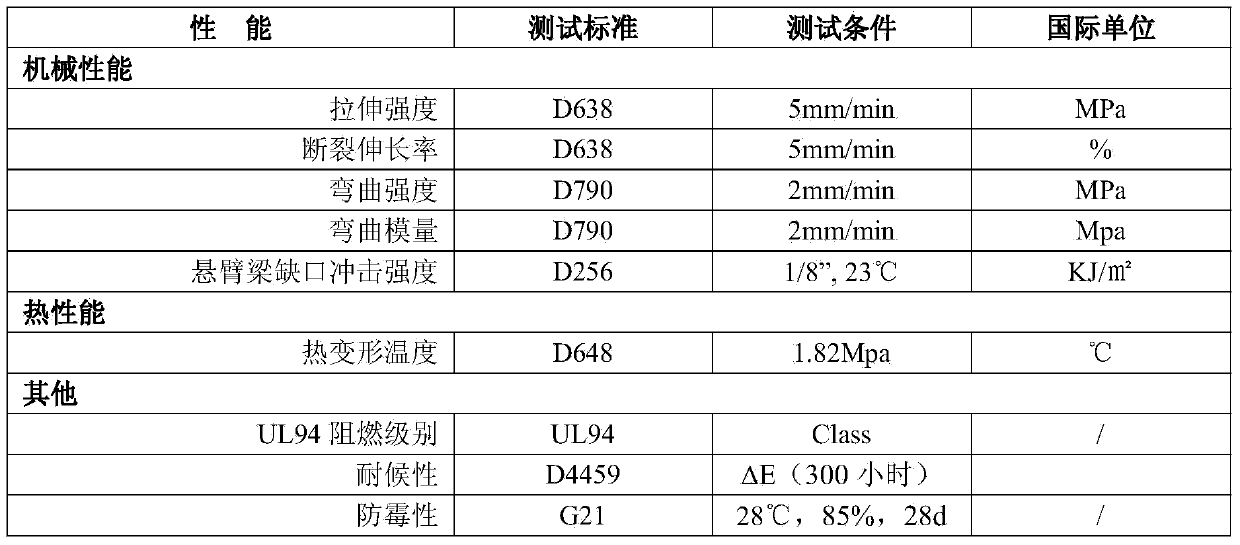

[0017] A weather-resistant, mildew-proof, and anti-bacterial polycarbonate composition according to each embodiment of the present invention is prepared by extruding and granulating after mixing the components uniformly to obtain a cold-resistant, mildew-proof, and anti-bacterial polycarbonate resin polymer. In the above examples and comparative examples, a high-speed mixer was used for mixing, and a 75L twin-screw extruder was used for extrusion with a rotation speed of 450r / min. The te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com