Constant-temperature constant-humidity wine cellar

A constant temperature and humidity, wine cellar technology, applied in wine cellar appliances, biochemical equipment and methods, etc., can solve the problems of moldy wine cellar, smallpox condensation water corrosion, poor thermal insulation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

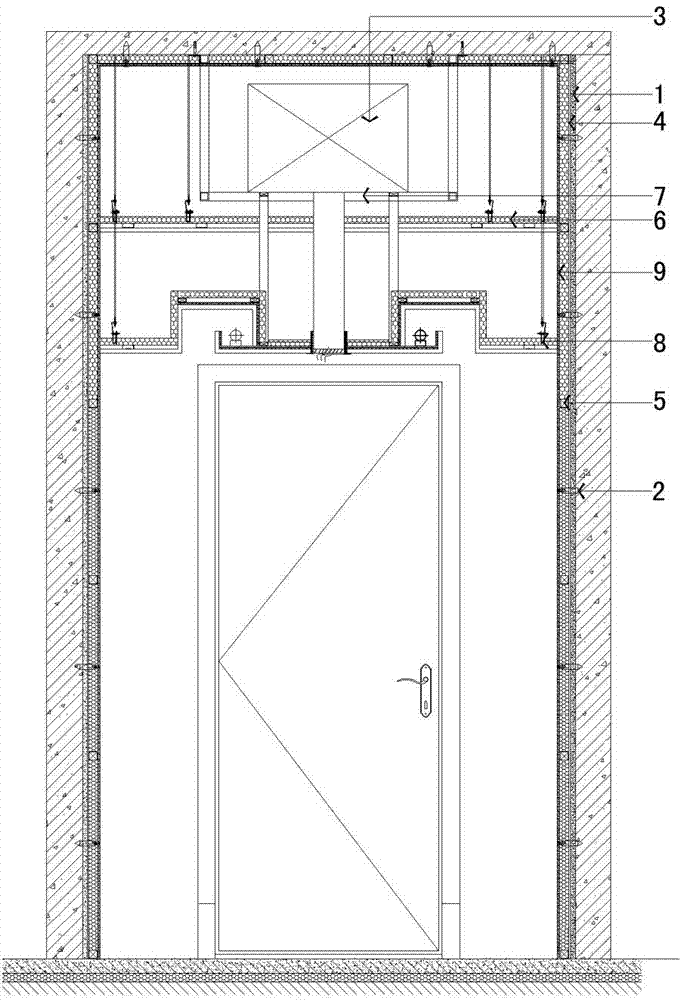

[0023] Example: such as figure 1 Shown, a kind of wine cellar of constant temperature and humidity, it comprises air-conditioning unit 3, steel frame 7, wall surface insulation layer, insulation door, suspended ceiling.

[0024] Such as figure 2 As shown, the air-conditioning unit 3 is installed on the steel frame 7, and is arranged on the top of the wall through the steel frame 7; the lower end of the steel frame 7 is provided with a suspended ceiling, and the lower end of the air-conditioning unit 3 is connected to the room with an air duct, and the suspended ceiling includes an upper ceiling and a lower ceiling. The steel frame 7 is fixed to the lower ceiling through galvanized steel pipes, and the 50mm keel skeleton 8 installed horizontally in the ceiling is covered with a glass fiber cotton layer 6; A light groove is arranged in the groove.

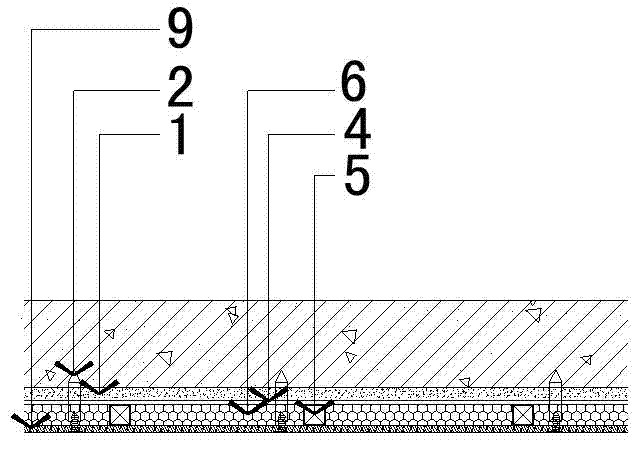

[0025] The wall temperature and humidity structure is provided with a moisture-proof cushion layer 4 with a thickness of 1mm, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com