Putty spraying machine

A putty sprayer and spray gun technology, which is applied in construction, building construction and other directions, can solve the problems of huge waste of working time, complicated mechanical assembly, and high labor waste rate, and achieves low manufacturing cost, labor saving, and work efficiency improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

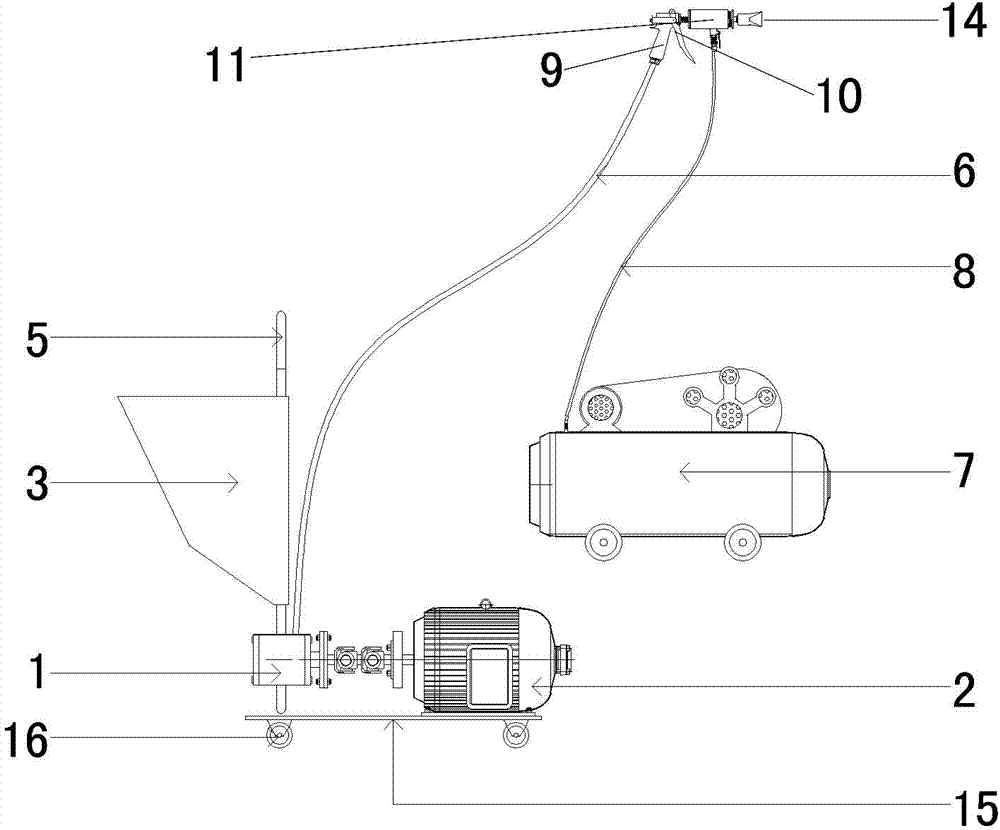

[0030] Example: such as figure 1 Shown, a kind of putty spraying machine, it comprises feeding mechanism, air compressor 7, pressure spray gun.

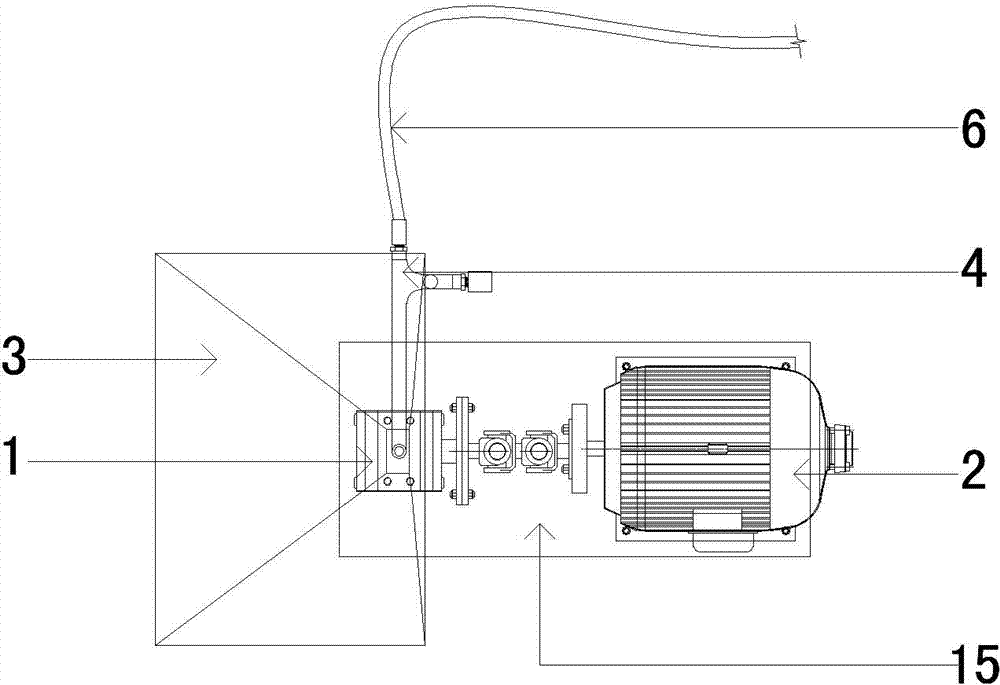

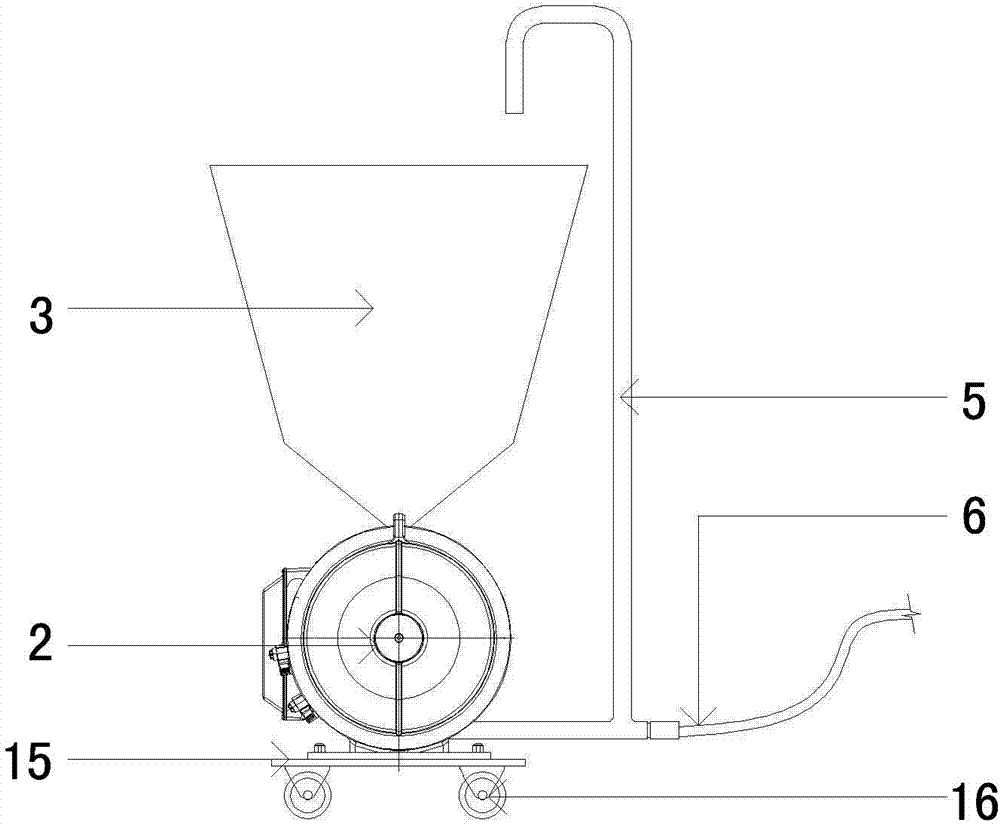

[0031] Such as figure 2 , image 3 As shown, the feeding mechanism includes a motor 2, a gear pump 1, and a feed hopper 3. The motor 2 is a 7.5KW, 380V motor, and the model of the gear pump 1 is WBZ-63. The feeding mechanism is installed on the galvanized steel plate 15 with universal wheels 16 for easy movement; the motor 1 is connected with the gear pump 1, the feeding hopper 3 is set at the feeding port on the upper part of the gear pump 3, and the connecting pipe 4 is connected Connecting to the outlet end of the gear pump 1, the connecting pipe 4 is connected to the feeding handle 9 of the pressure spray gun through the feeding hose 6; the connecting pipe 4 is a three-way pipe, and the third port of the three-way pipe is connected to the metal pipe 5, and the metal pipe The outlet faces the feed hopper 3, and the metal pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com