Bead head nozzle electrostatic spinning device

A technology of electrospinning and bead-head nozzles, applied in textile and papermaking, filament/thread forming, fiber processing, etc., can solve problems such as needle blockage and inconvenient cleaning, and achieve the effect of improving working speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

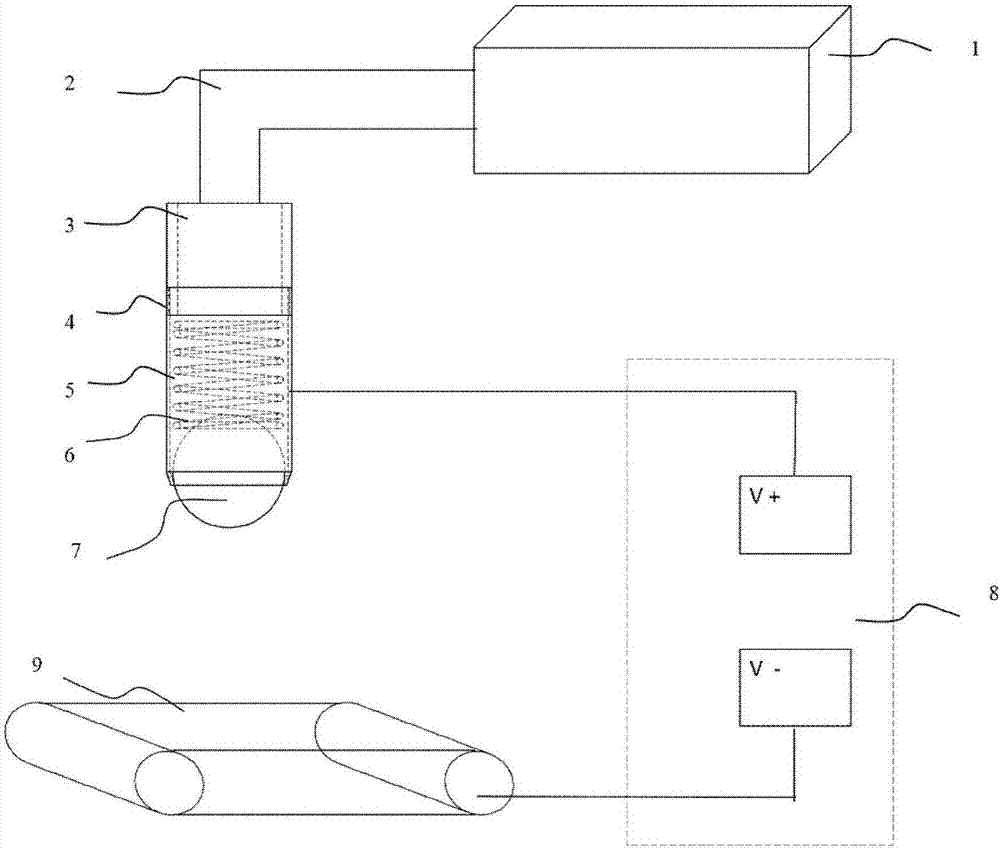

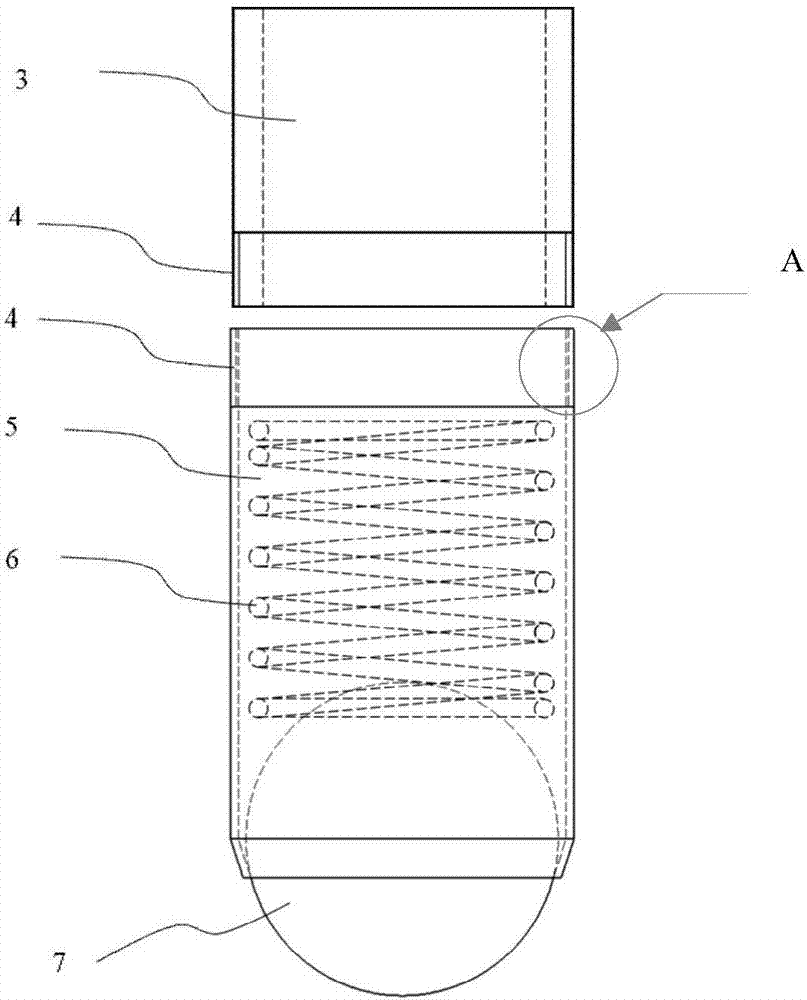

[0032] The spinning experiment of embodiment adopts bead nozzle electrostatic spinning device of the present invention (referring to figure 1 ), the closing part of the bead-head electrospinning nozzle is properly processed so that the closing part of the round platform at the lower part of the liquid outlet tube contacts with the sphere to form a slit. The bead head is made of metal stainless steel with a diameter of 0.5mm; the configured 3% The PVP solution is added to the propulsion pump device, and the PVP solution is supplied to the bead-head spinning system through the liquid inlet pipe. The vertical spinning method is adopted. When the high-voltage power supply reaches 12KV and the receiving distance is 1cm, the electrospinning effect is the best. Silk rate 0.005ml / min.

Embodiment 2

[0034] The spinning experiment of embodiment adopts bead nozzle electrostatic spinning device of the present invention (referring to figure 1 ), the closing part of the bead-head electrospinning nozzle is properly processed so that the closing part of the round platform at the lower part of the liquid outlet pipe contacts with the sphere to form a slit. The bead head is made of metal stainless steel with a diameter of 6.3mm. 5% of the configured The PVP solution is added to the propulsion pump device, and the PVP solution is supplied to the bead-head spinning system through the liquid inlet pipe. The vertical vertical spinning method is adopted. When the high-voltage power supply reaches 12KV and the receiving distance is 7cm, the electrospinning effect is the best. Rate 0.1ml / min.

Embodiment 3

[0036] The spinning experiment of embodiment adopts bead nozzle electrostatic spinning device of the present invention (referring to figure 1 ), the closing part of the bead-head electrospinning nozzle is properly processed so that the closing part of the round table at the lower part of the liquid outlet tube contacts with the sphere to form a slit. The bead head is made of metal copper and has a diameter of 6.3mm. The PVP solution is added to the propulsion pump device, and the PVP solution is supplied to the bead-head spinning system through the liquid inlet pipe. The vertical vertical spinning method is adopted. When the high-voltage power supply reaches 12KV and the receiving distance is 7cm, the electrospinning effect is the best. Rate 0.1ml / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com