Construction method of large-span multi-curvature thin-shell reinforced concrete structures

A reinforced concrete and construction method technology, applied in the direction of formwork/formwork/work frame, building structure, and on-site preparation of building components, which can solve the problems of concrete slippage, difficulty in positioning and height control of vertical poles, and load-bearing of glass fiber reinforced plastic formwork The capacity can not meet the requirements and other problems, to achieve the effect of force balance, solve the oblique thrust, and save construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

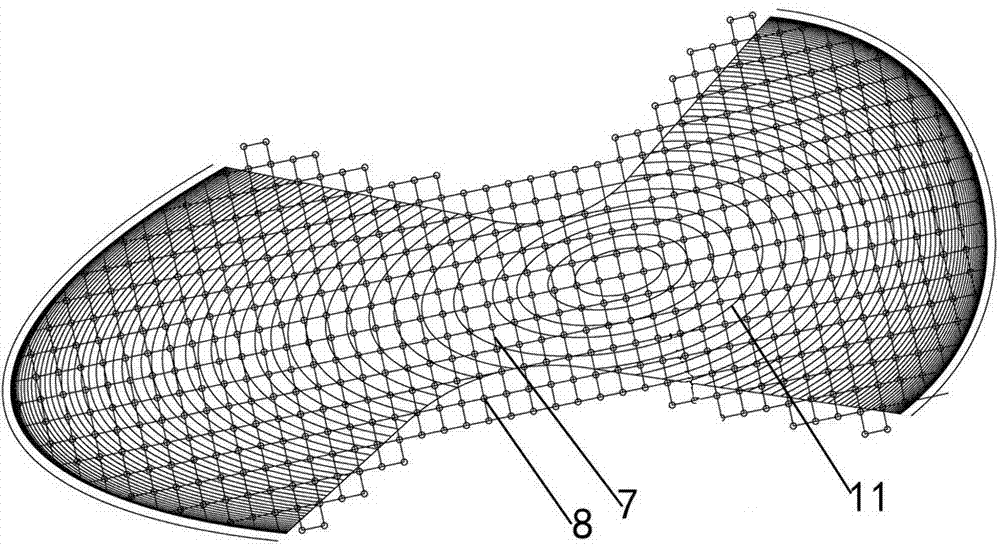

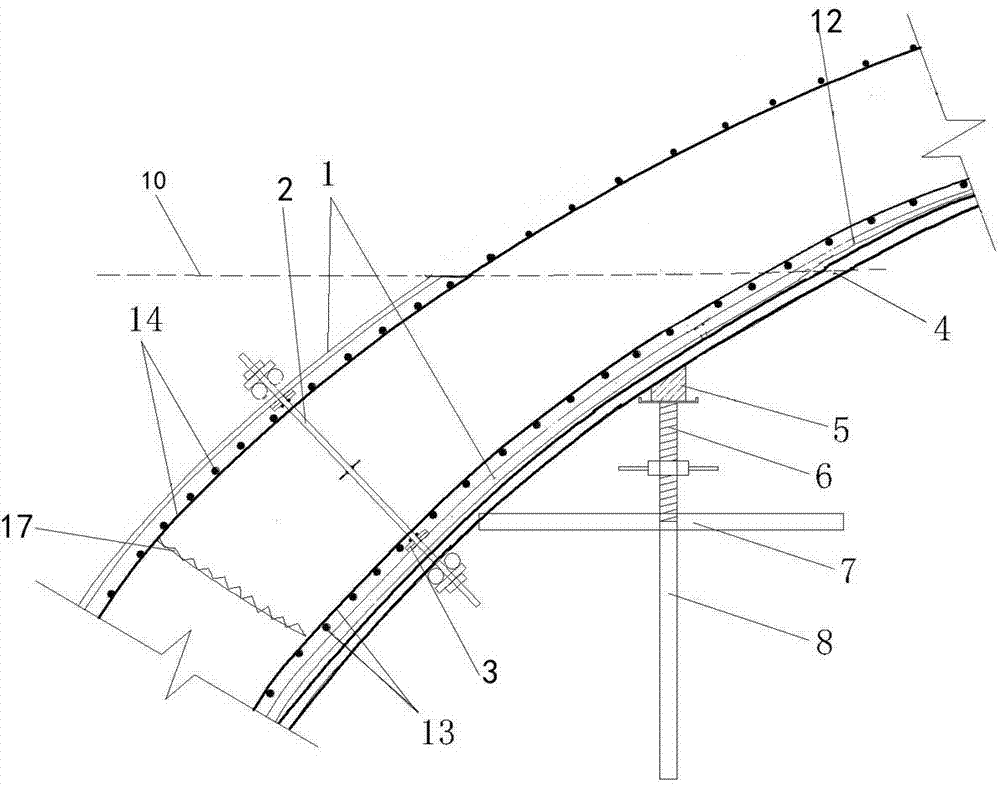

[0043] The eggshell-shaped reinforced concrete structure involved in the embodiment of the present invention is the exterior decoration structure of the gate. Designed according to the reasonable service life of 50 years, the safety level of the building structure is Class II, and the seismic fortification intensity is 8 degrees, such as Figure 4 As shown, the elevation of the top of the eggshell-shaped reinforced concrete structure of the present invention is 4.45m, the span of the shell is 42m, which is relatively large, and the surface curvature of the structure varies widely and irregularly, which makes the design and construction of the formwork difficult. .

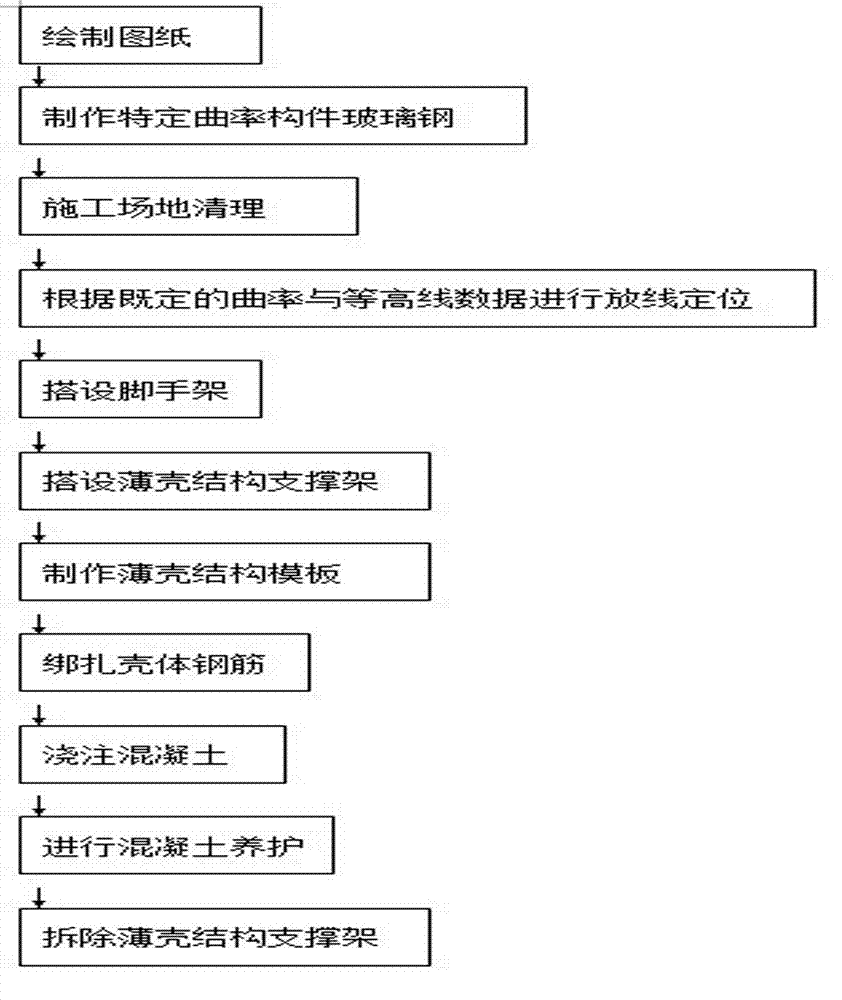

[0044] figure 1 It is the construction flowchart of the large-span multi-curvature thin-shell reinforced concrete structure construction method of the present invention, and the specific construction method is as follows:

[0045] 1 Draw construction drawings

[0046]Draw the 3D model diagram through the Rhino s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com