Hot air isolating door of thermal power station coal mill

A hot air isolation door, coal mill technology, applied in windows/doors, door/window accessories, door/window applications, etc., can solve the problems of incomplete soot blowing, incomplete door closing, fragile and other problems, and achieve good economic benefits and social effects, high degree of intelligence, and the effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

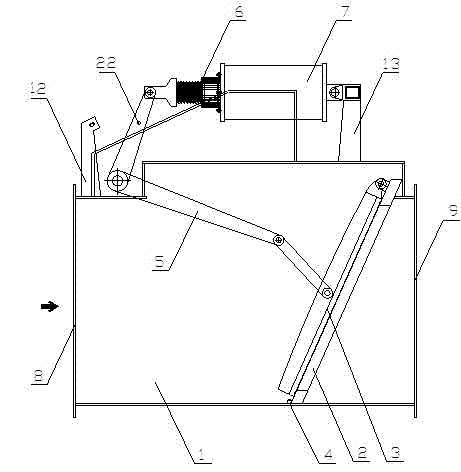

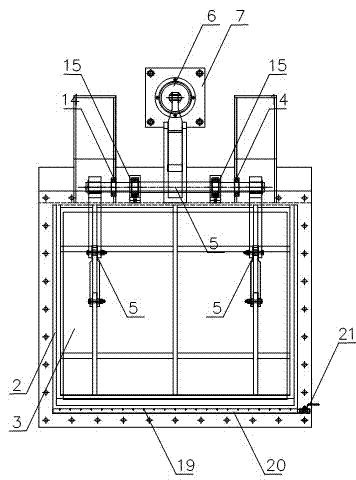

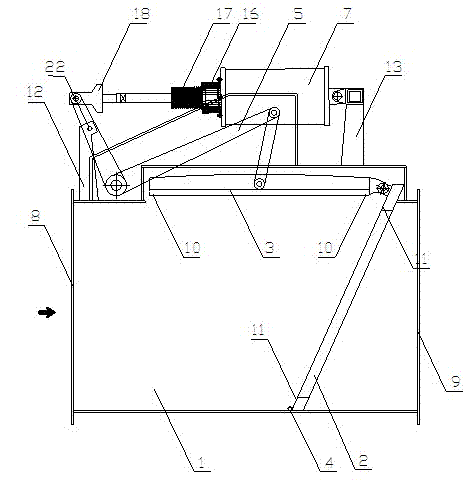

[0019] Such as figure 1 , figure 2 and image 3 As shown, the hot air isolation door of a coal mill in a thermal power station includes an air duct door body 1, a door frame 2, a door panel 3, a soot blowing mechanism 4, a four-link transmission mechanism 5, a buffer device 6 and a driving cylinder 7. The air duct door body 1 is a rectangular duct with a cross section, and its two ends are respectively an air inlet 8 and an air outlet 9; the door frame 2 is fixed at one end of the air outlet 9 of the air duct door body 1 at a certain angle; The upper side of the door panel 3 is hinged with the upper side of the door frame 2, and when the door panel 3 is attached to the door frame 2, the door panel 3 is pressed on the door frame 2, and there is an Ω-shaped hard seal 10 around the adjacent surfaces of the door frame 2 and the door panel 3, and the There is a circumferential groove 11 on the other adjacent surface corresponding to the Ω-shaped hard seal 10, and when the door p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com